MAINTENANCE

-32-

For Machines Mfg. Since 8/09

Model SB1018

MAINTENANCE

Maintenance Schedule

Daily

• Check/correctloosemountingbolts.

• Check/correct damaged or dull saw blade.

• Check/correct worn or damaged wires.

• Clean/protect table.

• Cleanmetalchipsfromupperandlower

wheel areas, and empty the chip chute.

• Correct any other unsafe condition.

Monthly

• CheckforV-belttension,damage,orwear.

• Lubricateall components outlined in this

section, with the exception of the gearbox.

Yearly

• Lubricate gearbox.

Always disconnect

machine from power before

performing maintenance or

serious personal injury may

result.

!

Cleaning

Use a brush and a shop vacuum to remove chips

andotherdebrisfromthemachine.Keepthe

non-painted surfaces rust-free with a quality rust

preventative.

Periodically, remove the blade and thoroughly

clean all metal chips or built-up grease from the

wheel surfaces and blade housing.

Lubrication

Before applying lubricant, wipe the area clean for

best results.

Lubricate the following areas

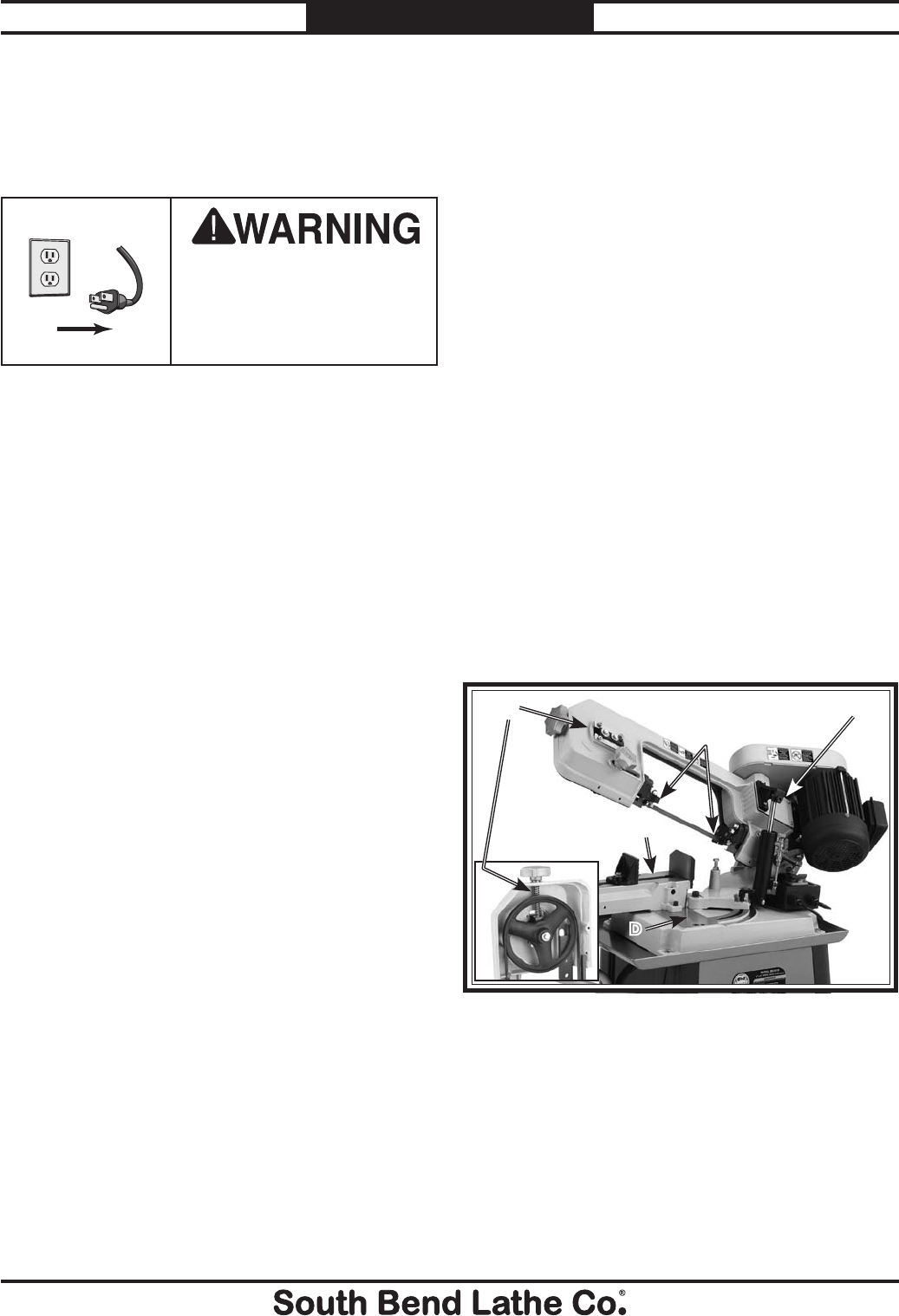

A. Blade Tension Mechanism: Open the main

blade guard, and apply a few drops of oil on

the tension knob lead screw.

B. Blade and Guides: Apply a few drops of

light machine oil on the blade and the blade

guides daily.

C. Gear Box: Change the gear oil annually

(Page 33).

D. Table and Machined Surfaces: Keepbare

metal surfaces rust-free with regular

applications of a quality rust preventative.

For long term storage you may want to

consider products like Boeshield T-9™.

E. Vise Leadscrew: Clean the leadscrew,

then paint it with multi-purpose grease as

needed.

Figure 43. Lubrication points.

A

B

C

D

E

For optimum performance from your machine,

follow this maintenance schedule and refer to

any specific instructions given in this section.