SERVICE

For Machines Mfg. Since 8/09 Model SB1020

-37-

SERVICE

Blade Brush Angle Stops

The Model SB1020 has a blade brush to help

keep metal chips off the blade wheels. It will

wear over time and require re-adjustment when

it no longer contacts the blade.

Tools Needed Qty

Hex Wrench 4mm .................................................1

To adjust the blade brush:

1. DISCONNECT BANDSAW FROM POWER!

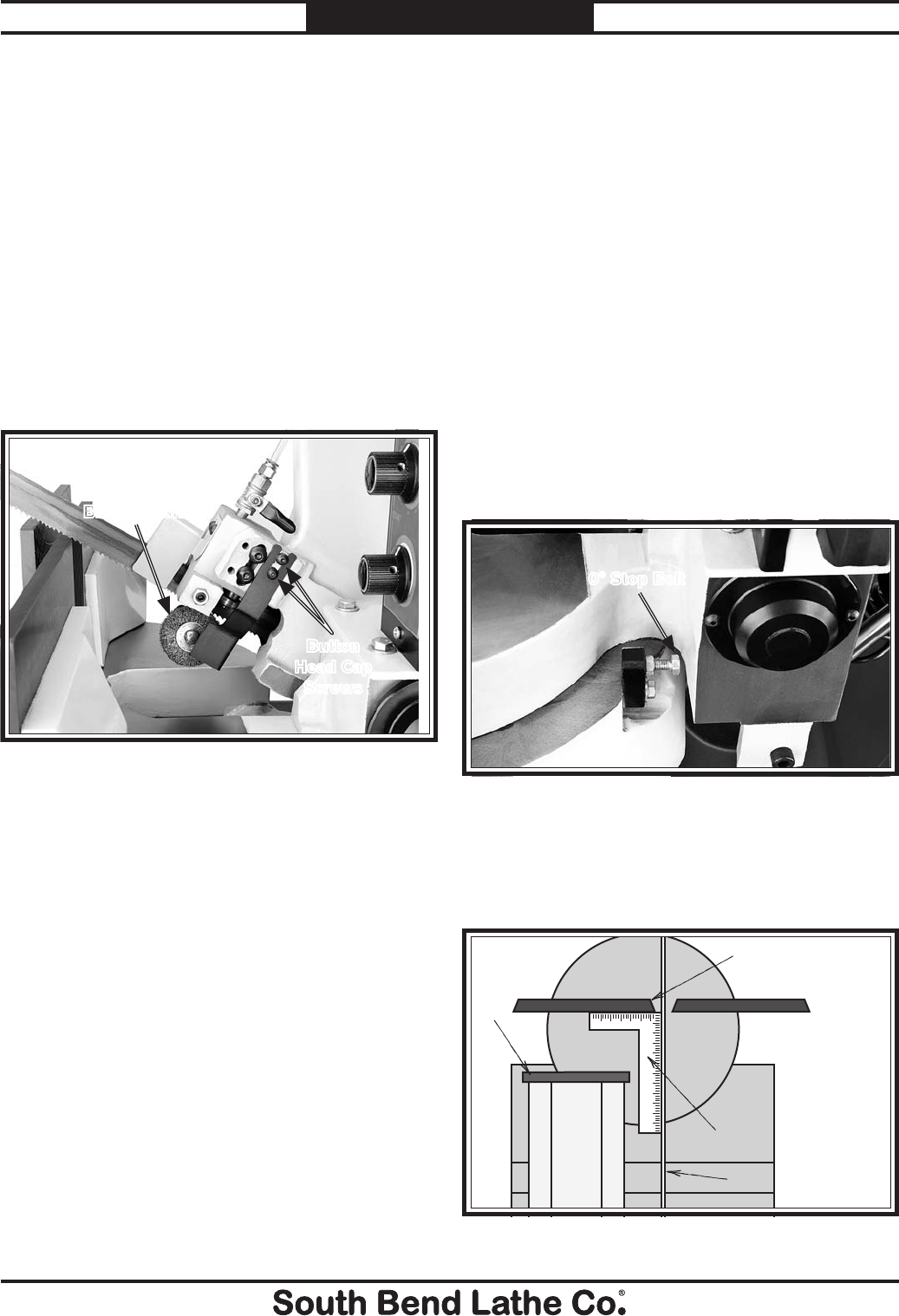

2. Loosen the button head cap screws shown in

Figure 41.

The swivel base is equipped with three angle

stops to provide quick adjustments to 60° to the

left, 0°, and 45 to the right°. If cuts made using

these stops are not sufficiently accurate, the

stops will need to be adjusted.

Tools Needed Qty

Wrench 12mm .......................................................1

To adjust the angle stops:

1. DISCONNECT BANDSAW FROM POWER!

2. Rotate the headstock to the right

approximately 10°, engage the 0° angle stop

(Figure 42) by flipping it up, then rotate the

headstock to the left until it stops against

the 0° stop. Tighten the headstock lock lever.

Figure 41. Blade brush adjustments.

Blade Brush

Button

Head Cap

Screws

Figure 42. 0° Angle stop.

0° Stop Bolt

3. Slide the blade brush bracket as needed so

the blade extends approximately

1

⁄8" into the

bristles of the brush. Hold the bracket in

position, then re-tighten the button head cap

screws.

Figure 43. Testing vise/blade squareness.

Stationary Jaw

Movable

Jaw

Square

Blade

Vise

45° R

60° L

3. Lower the headstock, then place a square

flat on the table and against both the

stationary jaw and the blade, as shown in

Figure 43.