-38-

For Machines Mfg. Since 8/09

Model SB1020

SERVICE

The Model SB1020 is equipped with limit

switches that prevent the saw from operating

if the blade is not properly tensioned and stop

the saw motor when it reaches the end of a cut.

If either of these functions does not operate

correctly, you will need to adjust the appropriate

limit switch.

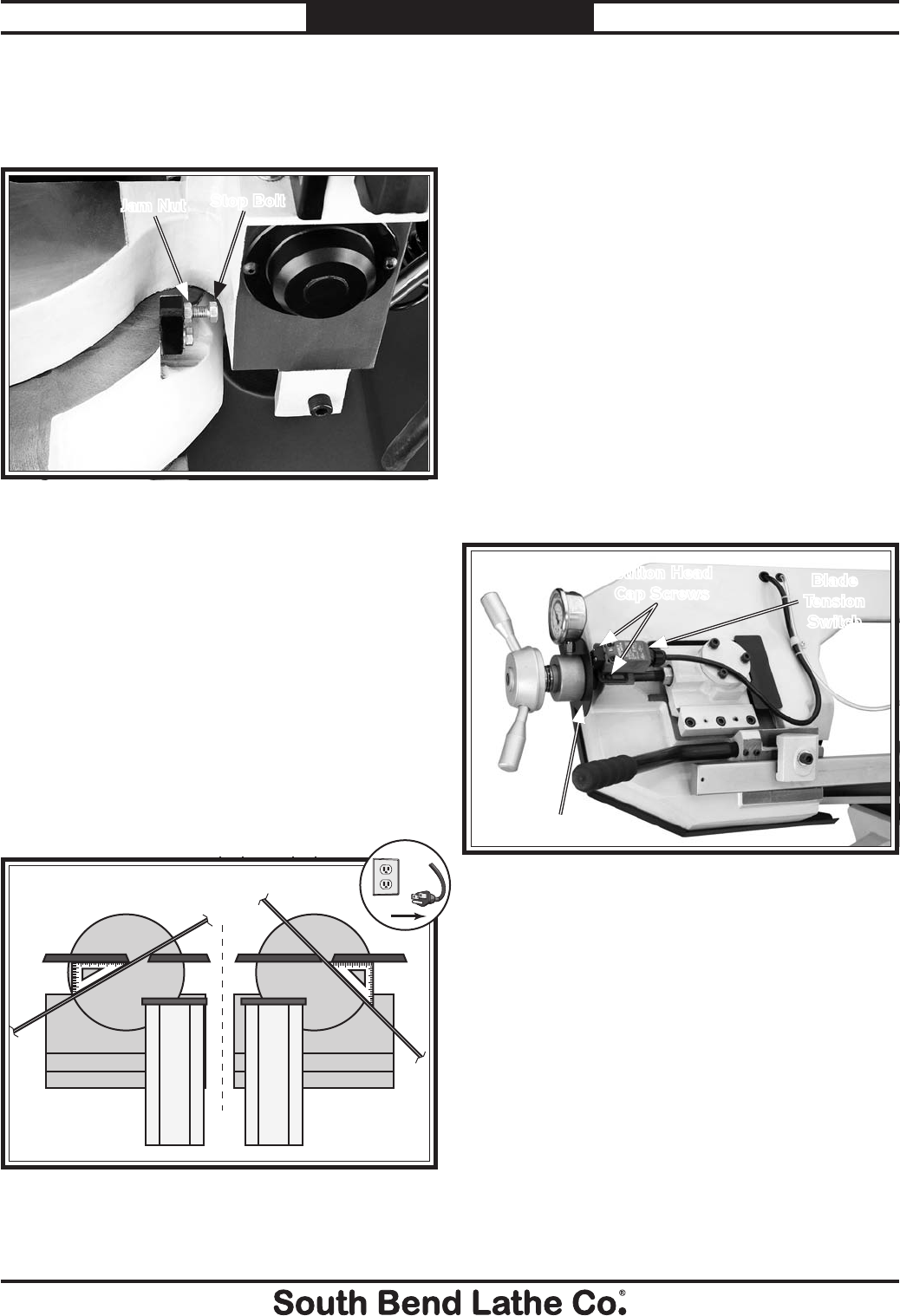

To adjust the blade tension switch:

1. DISCONNECT BANDSAW FROM POWER!

2. Tension the blade until the tension gauge

reads 20,000 PSI, which is the transition

from yellow to green.

3. Use a 3mm hex wrench to loosen the two

button head cap screws that secure the blade

tension switch bracket shown in Figure 46.

Limit Switches

Figure 44. Stop adjustment.

Jam Nut

Stop Bolt

4. If the square does not fit snugly against both

the stationary jaw and the blade, loosen the

jam nut shown in Figure 44, then thread

the stop bolt inward.

5. Loosen the headstock lock lever, rotate the

headstock so that the blade is square to

the vise, then re-tighten the headstock lock

lever.

6. Adjust the stop bolt as needed until it just

touches the cast iron swivel base, as shown

in Figure 44, then snug the jam nut against

the stop block without turning the stop bolt.

7. Repeat this procedure for the 60° left and 45°

right stops using a 45° square and a 30°/60°

triangle (or an adjustable square), as shown

in Figure 45.

Figure 45. 60° left and 45° right stop adjustment.

Stationary Jaw

Movable

Jaw

Square

Blade

Vise

45° R

60° L

!

Figure 46. Blade tension limit switch.

Switch Plate

Button Head

Cap Screws

Blade

Tension

Switch

4. Slide the switch away from the switch plate

to make sure it releases, then slowly slide it

back towards the switch plate just until you

hear the switch click. Hold it in this position,

the re-tighten the button head cap screws.

5. Release tension from the blade. If the switch

does not immediately click again, signaling

that tension has been released, repeat Steps

3–4, slightly adjusting the switch away from

the switch plate.