17

MAINTENANCE

WARNING:

When servicing use only identical replacement parts. Use of any other parts may create

a hazard or cause product damage.

WARNING

To avoid serious personal injury make sure the drill press is turned OFF and the cord is

unplugged from the power source before performing any maintenance or adjustment.

GENERAL MAINTENANCE

After using your drill press, clean it completely and lubricate all sliding and moving parts.

Apply a light coat of automotive type paste wax to the table and column to help keep

the surfaces clean.

LUBRICATION

The ball bearings in the quill and V-belt pulley are permanently lubricated. To lubricate

the spindle, pull quill down to maximum depth and oil moderately once every three

months. Oil all slide bars lightly every two months. If cranking becomes difficult, grease

bracket lightly.

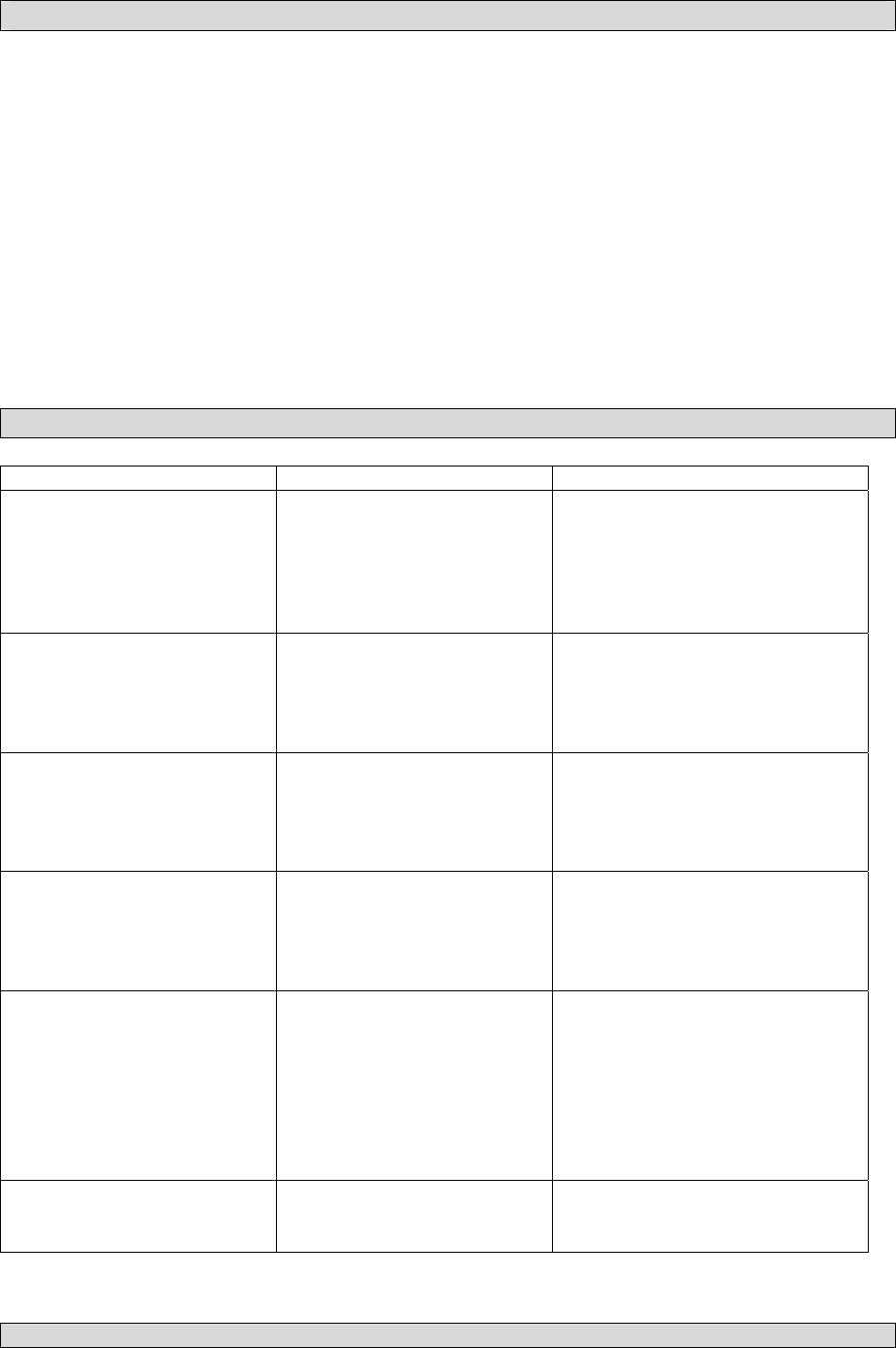

TROUBLE SHOOTING

TROUBLE PROBABLE CAUSE REMEDY

Noisy operation

A) Incorrect belt tension

B) Dry spindle

C) Loose pulley

D) Loose belt

E) Bad bearing

A) Adjust tension

B) Remove spindle/quill

assembly and lubricate

C) Tighten pulley

D) Adjust belt tension

E) Replace bearing

Excessive drill wobble

A) Loose chuck

B) Worn spindle shaft or

bearing

C) Bad chuck

A) Tighten by pressing

chuck down against table

B) Replace spindle shaft

or bearing

C) Replace chuck

Motor won’t start

A) Power supply

B) Motor connection

C) Switch connections

D) Motor windings burned

E) Bad switch

A) Check power cord

B) Check motor connection

C) Check switch connections

D) Replace motor

E) Replace speed

Drill binds in workpiece

A) Excessive pressure

on feed handle

B) Loose belt

C) Loose drill

D) Speed too fast

A) Apply less pressure

B) Check belt tension

C) Tighten drill with key

D) Change speed

Drill burns or smokes

A) Incorrect speed slow

down RPM

B) Chips are not

discharging

C) Dull drill or not cut

properly for material

D) Needs lubrication

E) Feed pressure wrong

A) Refer to speed chart

B) Clean drill

C) Clean sharpness and

taper

D) Use lubrication while

drilling

E) Apply less pressure

Table difficult to raise A) Needs lubrication

B) Bent rack

C) Table lock tightened

A) Lubricate with light oil

B) Straighten rack

C) Loosen clamp

SERVICE CENTER