ProSpray3.29•3.31 13

GB

Cleaning the unit (shutting down)

8. Cleaning the unit (shutting down)

A clean state is the best method of ensuring operation without

problems.Afteryouhavenishedspraying,cleantheunit.Under

no circumstances may any remaining coating material dry and

harden in the unit.

The cleaning agent used for cleaning (only with an igni tion point

above21°C)mustbesuitableforthecoatingmaterialused.

• , refer to the operating manual of

the spray gun.

Clean and remove tip.

For a standard tip, refer to Page 19, Section 12.2.

If a non-standard tip is installed, proceed according to the

relevant operating manual.

1. Remove suction hose from the coating material.

2. Closethereliefvalve,valvepositionSPRAY(p spray).

3. SwitchtheunitON.

4. Pull the trigger of the spray gun in order to pump the

remaining coating material from the suction hose, high-

pressure hose and the spray gun into an open container.

Attention

5. Immerse suction hose with return hose into a container

with a suitable cleaning agent.

6. Turnthepressurecontrolknobintothebluezone-

pulsating pressure for unit cleaning.

7. Open the relief valve, valve position PRIME

(k circulation).

8. Pump a suitable cleaning agent in the circuit for a few

minutes.

9. Closethereliefvalve,valvepositionSPRAY(p spray).

10. Pull the trigger of the spray gun.

11. Pump the remaining cleaning agent into an open container

until the unit is empty.

12. Switch the unit OFF.

Attention

Never spray down the unit with high-pressure or

Wipe down unit externally with a cloth which has been immersed

in a suitable cleaning agent.

Cleantheltercartridgeregularly.

Asoiledorcloggedhigh-pressureltercancauseapoorspray

pattern or a clogged tip.

1. Turnthepressureregulatorknobintotheblackzoneuntil

it stops (no pressure).

2. Open the relief valve, valve position PRIME

(k circulation).

3. Switch the unit OFF.

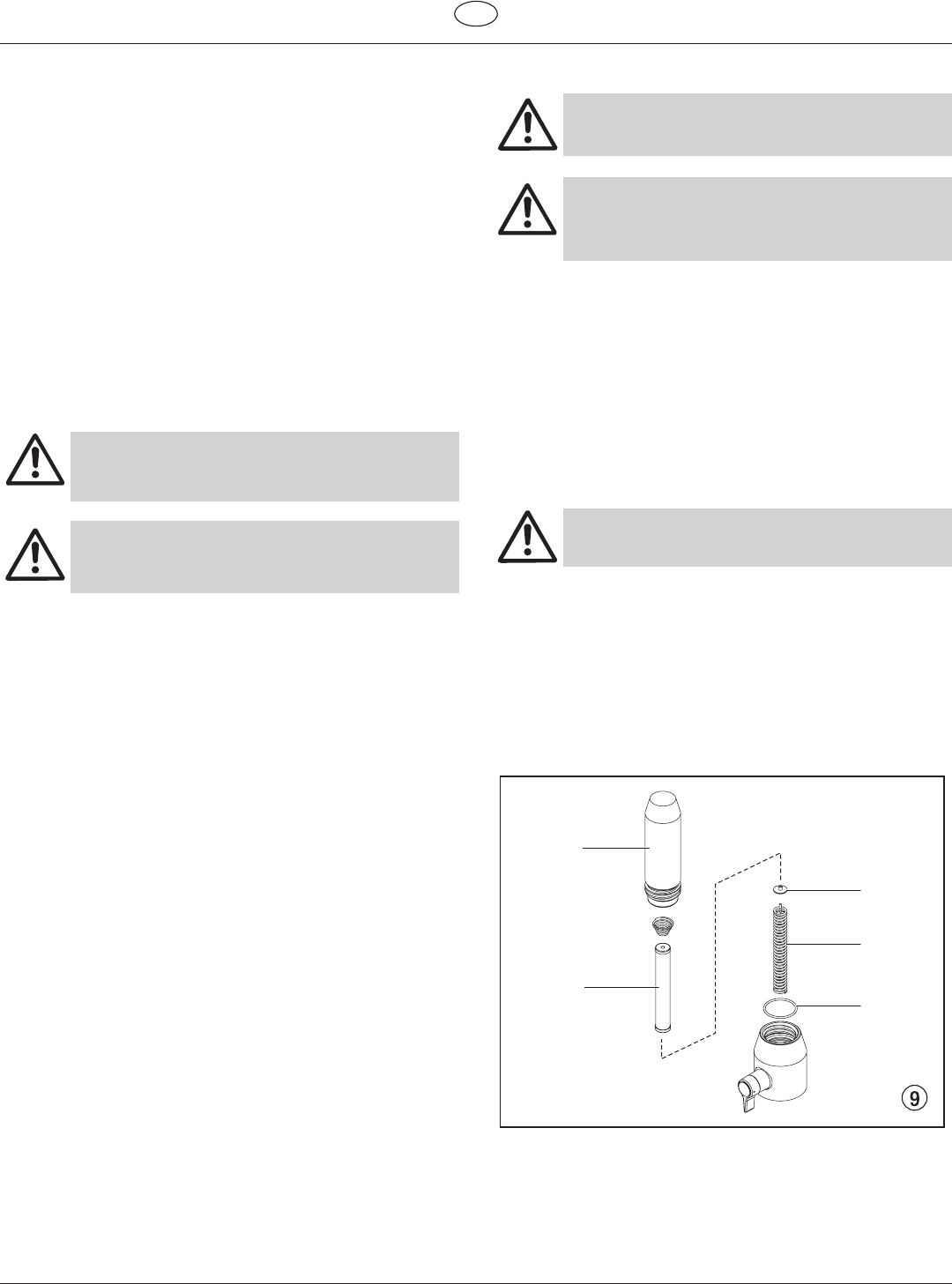

4. Unscrewthelterhousing(Fig.9,Item1).withastrap

wrench.

5. Pulltheltercartridge(2)fromthebearingspring(3).

6. Clean all the parts with the corresponding cleaning agent.

Ifnecessary,replacetheltercartridge.

7. Check the O-ring (4), replace it if necessary.

8. Place the bearing ring (5) against the bearing spring (3).

Slidetheltercartridge(2)overthebearingspring.

9. Screwinlterhousing(1)andtightenitasfaraspossible

with the strap wrench.

1

2

3

5

4