14

Maintenance

Replacing blades

1. Disconnect the saw from its electrical power source to

prevent accidental start-ups.

2. Raise the saw arm to its full vertical position and lock it

in place using the quick shut off valve on the hydraulic

control cylinder.

3. Lift the safety cover in the lower portion of the blade

guard door by sliding it upward. There is no need to

remove it completely from its slot.

4. Remove the two screws with plastic knobs which hold

the blade guard door closed and swing the door open to

expose the drive and idler wheels, and the blade.

5. Turn the blade tension handle counterclockwise until

the blade hangs loose in the saw arm.

6. Use leather gloves to prevent cuts and scratches and

use protective eyewear which meets ANSI Specification

Z87.1. and pull the blade off of the drive wheels and out of

the blade guides. Store the blade carefully before

proceeding.

7. Slide the new blade into the blade guides -- then loop

the blade over the upper and lower drive wheels.

Note: it is possible to install the blade backwards. The

teeth on the blade should be pointing downward, toward

the motor, at the time the blade is installed.

8. Push the blade so it is seated against the shoulders of

the wheels. When it is seated against the shoulders...

9. ...turn the blade tension wheel clockwise to increase

tension on the blade. Don't over-tension the blade.

Tension it enough so it doesn't slip while cutting.

10. When you are satisfied that the saw is tensioned

correctly, reconnect the saw to its electrical power source.

11. Check the tracking of the blade according to

instructions in the section on Adjusting blade tracking,

below.

12. Close the wheel guard door and secure it using the

two plastic knobbed screws.

13. Slide the safety cover downward in its slot until it is

fully closed.

14. The new blade is installed and ready for the Blade

break-in procedures.

Adjusting blade tracking

If the blade is fully tensioned, release tension

slightly before attempting to adjust the saw blade tracking.

A badly worn or bent blade will be extremely difficult to

track properly -- if it can be tracked successfully, at all.

The track of the saw blade is adjusted using the track

adjustment mechanism on the idler wheel. The track

adjustment tilts the wheel to "steer" the blade on the

wheels. Tracking adjustment is performed with the saw

arm in vertical position, blade guard doors open and the

saw running. Therefore, USE EXTREME CAUTION

WHEN PERFORMING BLADE TRACKING CHECKS AND

ADJUSTMENTS.

To adjust blade tracking:

1. Loosen the sliding plate draw block bolt slightly so the

adjustment set screw will be able to move the draw block.

2. Turn the coolant pump switch OFF, if coolant is used.

3. Turn the saw ON.

4. Insert a 4mm hex wrench in the socket head track

adjustment set screw.

5. Turn the track adjustment set screw so the blade starts

to move away from the shoulder -- then immediately turn

the screw the other direction so the blade stops -- then

moves slowly toward the shoulder.

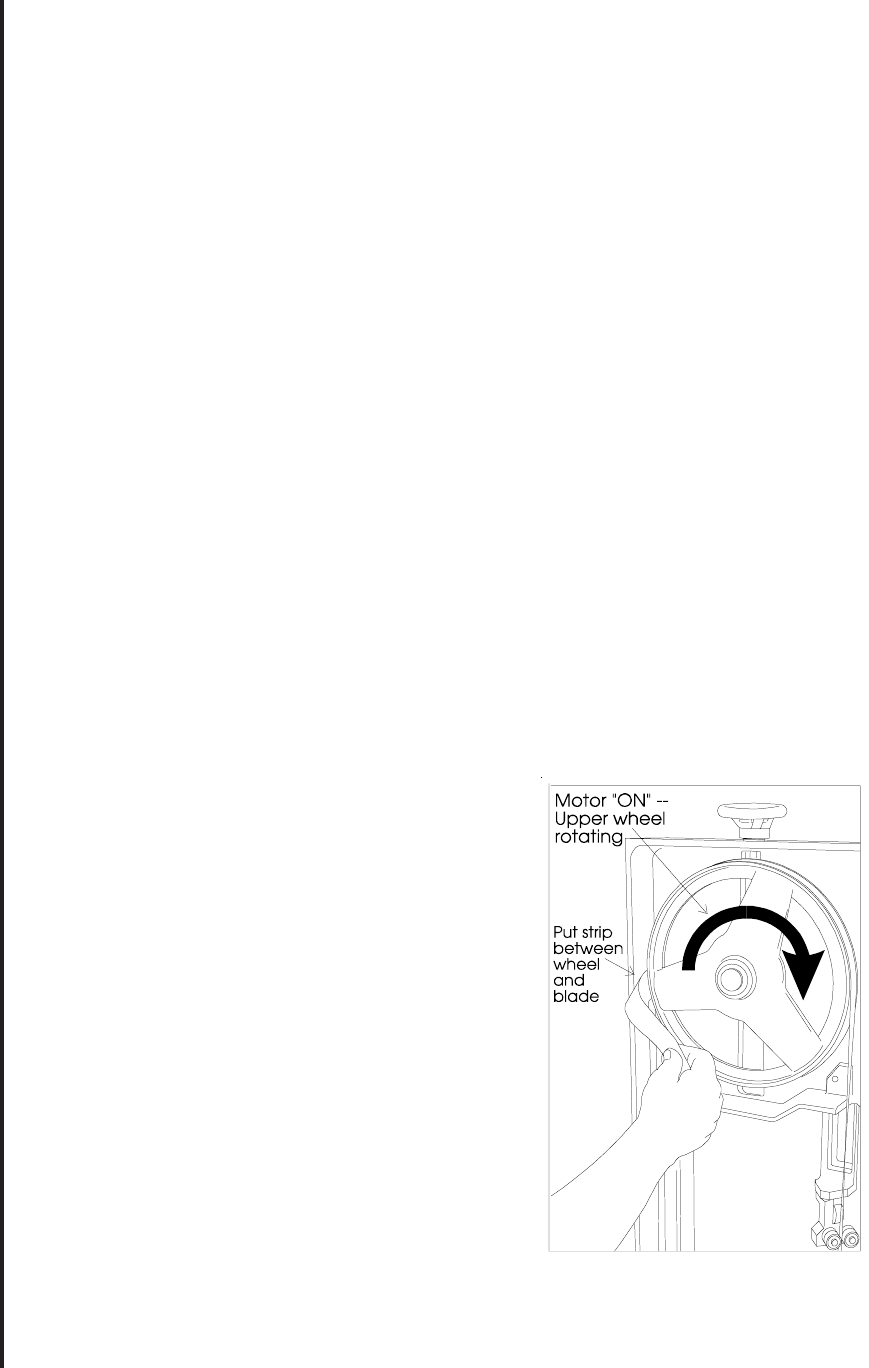

6. Use the blade tracking adjustment screw to stop the

motion of the blade on the wheel as it gets close to the

shoulder. Now, put a strip of paper between the blade and

wheel as shown in Figure 9. KEEP FINGERS CLEAR OF

THE BLADE AND WHEEL. (That's why the paper strip

should be at least 6 inches long.)

7. The paper should not be cut, this first attempt. Next,

turn the track adjustment set screw a tiny amount more

and repeat the insertion of the paper between the blade

and wheel.

You may have to repeat this step several times before the

blade and shoulder cut the paper into two pieces. Don't

be in a hurry. Patience and accuracy here will pay off with

better, more accurate, quieter cutting and much longer

machine and blade life.

8. When the paper is cut, turn the adjustment screw

counterclockwise, slightly. This assures that the blade is

not touching the shoulder of the wheel.

9. Tighten the two bolts which hold the draw block.

Figure 9: Inserting the paper strips between the blade

and wheel to adjust blade-to-shoulder clearance