User Connections 59

4

User Connections

Rear Panel Connections (All Models)

Make application load connections to the output terminals or bus bars, analog connector, and digital connector as shown on

the rear-panel drawing for your model power supply. These connections are organized by series as follows:

Series 664xA and 665xA

Series 667xA

Series 668xA and 669xA

Make controller connections (GPIB and serial link) as shown in Figure 4-6 at the end of this chapter.

Load Wire Selection (All Models)

Fire Hazard To satisfy safety requirements, load wires must be large enough not to overheat when

carrying the maximum short-circuit current of the power supply. If there is more than one load, then

any pair of load wires must be capable of safely carrying the full-rated current of the supply. With

the larger-capacity supplies (such as Series 668xA), use of two or more load wires in parallel may be

required.

Table 4-1 lists the characteristics of AWG (American Wire Gauge) copper wire.

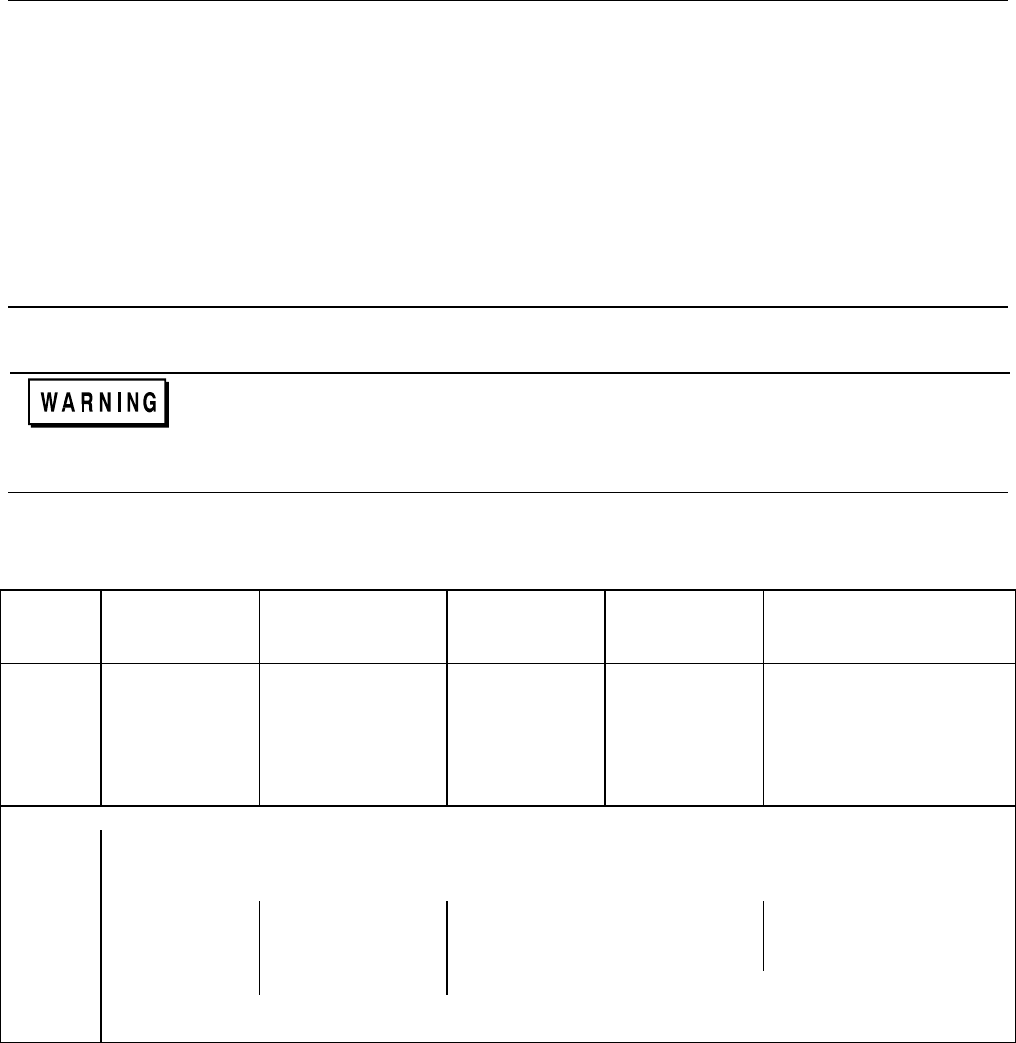

Table 4-1. Stranded Copper Wire Capacity and Resistance

AWG

Ampacity

l

Resistance

2

AWG

Ampacity

1

Resistance

2

No.

(Ω

ΩΩ

Ω/m)

No.

(Ω

ΩΩ

Ω/m)

14 25 0.0103 2 140 0.00064

12 30 0.0065 1/0 195 0.00040

10 40 0.0041 2/0 225 0.00032

8 60 0.0025 3/0 260 0.00025

6 80 0.0016 4/0 300 0.00020

4 105 0.0010

NOTES:

1. Ampacity is based on 30 °C ambient temperature with conductor rated at 60 °C. For ambient temperature other

than 30 °C, multiply the above ampacities by the following constants:

Temp (°C) Constant

Temp (°C) Constant

21-25 1.08 41-45 0.71

26-30 1.00 46-50 0.58

31-35 0.91 51-55 0.41

36-40 0.82

2. Resistance is nominal at 75 °C wire temperature.