Calibration 95

A

Calibration

Introduction

The power supply may be calibrated either from the front panel or from a controller over the GPIB. The procedures given

here apply to all models.

Important These instructions do not include verification procedures. If you need to perform verification as a

erequisite to or as part of your calibration procedure, see “Appendix B - Verification”.

Equipment Required

The equipment listed in Table A-1, or equivalent, is required for calibration.

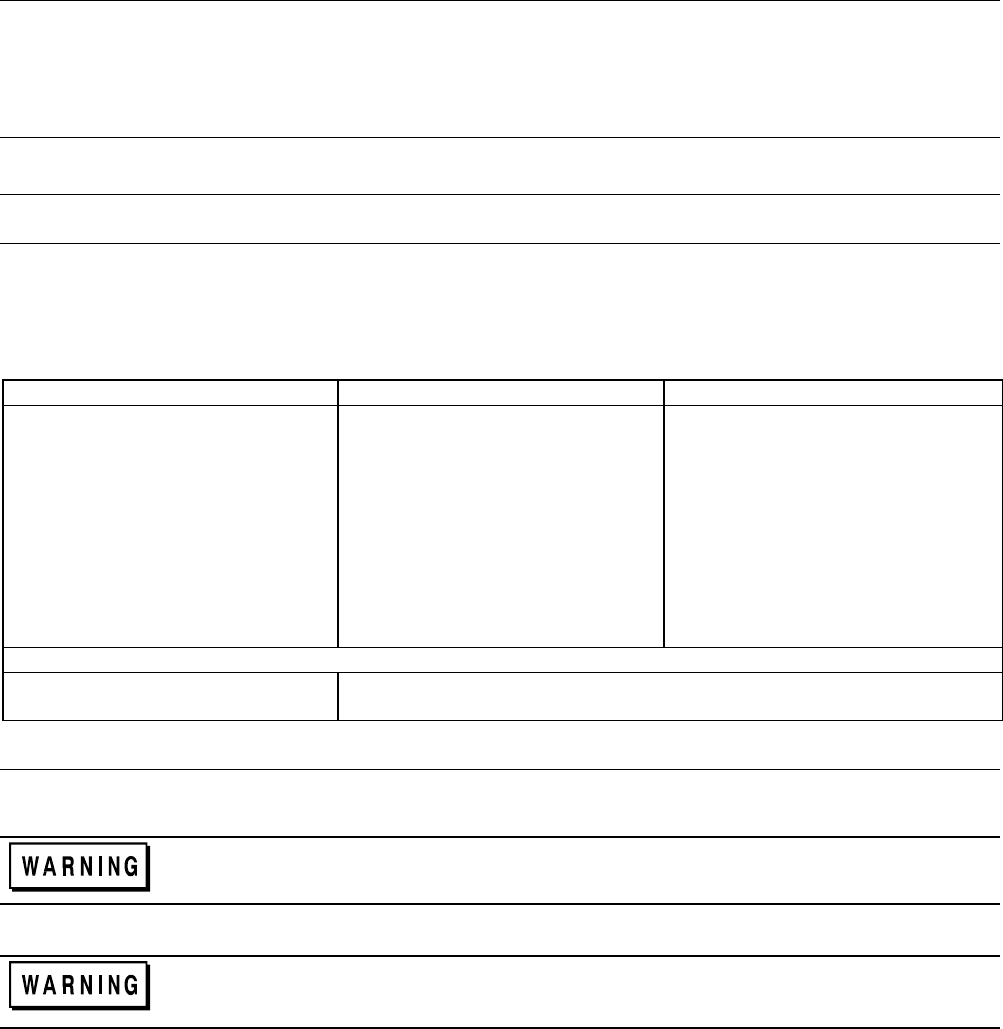

Table A-1. Equipment Required for Calibration

Equipment Characteristics Recommended Model

Voltmeter D-c accuracy 0.005%, 6 digits Agilent 3456A or 3458A

Shunt resistor

Agilent 6641A, 51A, 52A

100 A, 0.01 Ω, 0.04%, 100 W

Guildline 9230/100

Agilent 6642A, 43A, 44A, 45A,

6643A, 54A, 55A

15 A, 0.1 Ω, 0.04%, 25 W

Guildline 9230/15

Agilent 6671A

300 A, 0.001 Ω, 0.04%,100 W

Guildline 9230/300

Agilent 6672A, 73A, 74A, 75A

300 A, 0.001 Ω, 0.04%, 100 W

Guildline 9230/300

Agilent 6680A, 81A, 6690A

1000 A, 0.1 mΩ, 0.05%

Burster 1280S

Agilent 6682A, 83A, 84A,

6691A, 92A

300 A, 0.001 Ω, 0.04%,100 W

Guildline 9230/300

For Calibration Over the GPIB

GPIB Controller

IBM compatible PC with GPIB Interface

General Procedure

Because the power supply output must be enabled during calibration, voltages or currents

hazardous to personnel and/or damaging to equipment can appear at the output terminals.

ENERGY HAZARD. Series 668xA/669xA supplies can provide more than 240 VA at more than 2

V. If the output connections touch, severe arcing may occur resulting in burns, ignition or welding of

parts. Do not attempt to make connections to live output circuits.

Parameters Calibrated

The following parameters may be calibrated:

• Output voltage.

• Output voltage readback.