10

Operating Instructions and Parts Manual

Airless Paint Systems

www.chpower.com

Electrical System (Cont.)

REPLACEMENT OF ELECTRICAL

COMPONENTS

NOTE: Refer to Electrical System

Diagram (page 20) and LCD Diagram

(page 22).

PRESSURE CONTROL ASSEMBLY

(ELECTRICAL CONTROL BOARD)

1. Unplug machine's power cord.

2. Remove four screws from pressure

control assembly.

3. Disconnect all leads from pressure

control assembly.

4. Reassemble in reverse order.

SENSOR

1. Remove the screws and lower the

pressure control assembly.

2. Disconnect swivel from sensor by

holding sensor with 7/8" wrench

and loosening swivel with 11/16"

wrench.

3. Disconnect sensor lead from the

board. Carefully pull sensor lead

out of the terminal box and remove

sensor.

4. Reassemble in reverse order.

POTENTIOMETER

1. Lower pressure control assembly as

described above.

2. Disconnect potentiometer lead

from pressure control assembly.

3. Use a 1/16" allen wrench, loosen set

screw in the potentiometer knob

and remove knob and spacer.

4. Using a 1/2" wrench or deep socket,

remove the nut from the

potentiometer shaft assembly.

5. Pull entire potentiometer assembly

out of terminal box.

6. Replace in reverse order.

LIQUID CRYSTAL DISPLAY (LCD)

1. Lower pressure control assembly as

described above.

2. Unscrew the four nuts (6/32") and

remove LCD Display assembly.

3. If unable to loosen the four nuts,

hold them and unscrew the four

screws. Then remove the LCD

Display Assembly. If the display is

removed in this manner, the mylar

label must be replaced.

4. Reassemble in reverse order, while

making sure that the four spacers

and the four washers are in place.

Tighten the four nuts handtight

and seal with blue loctite. DO NOT

overtighten the nuts as this will

damage the display.

ON-OFF TOGGLE SWITCH

1. Lower the pressure control

assembly as described above.

2. Disconnect the two wires on the

switch.

3. Use a 9/16" wrench to loosen the

nut on the toggle switch shaft.

4. Reassemble in reverse order.

FUSE HOLDER

1. Lower pressure control assembly as

described above.

2. Disconnect the two wires on the

holder.

3. Remove holder cover and fuse.

4. Use 11/16" wrench to remove the

nut from the holder shaft.

5. Reassemble in reverse order.

Service

SPRAY GUN

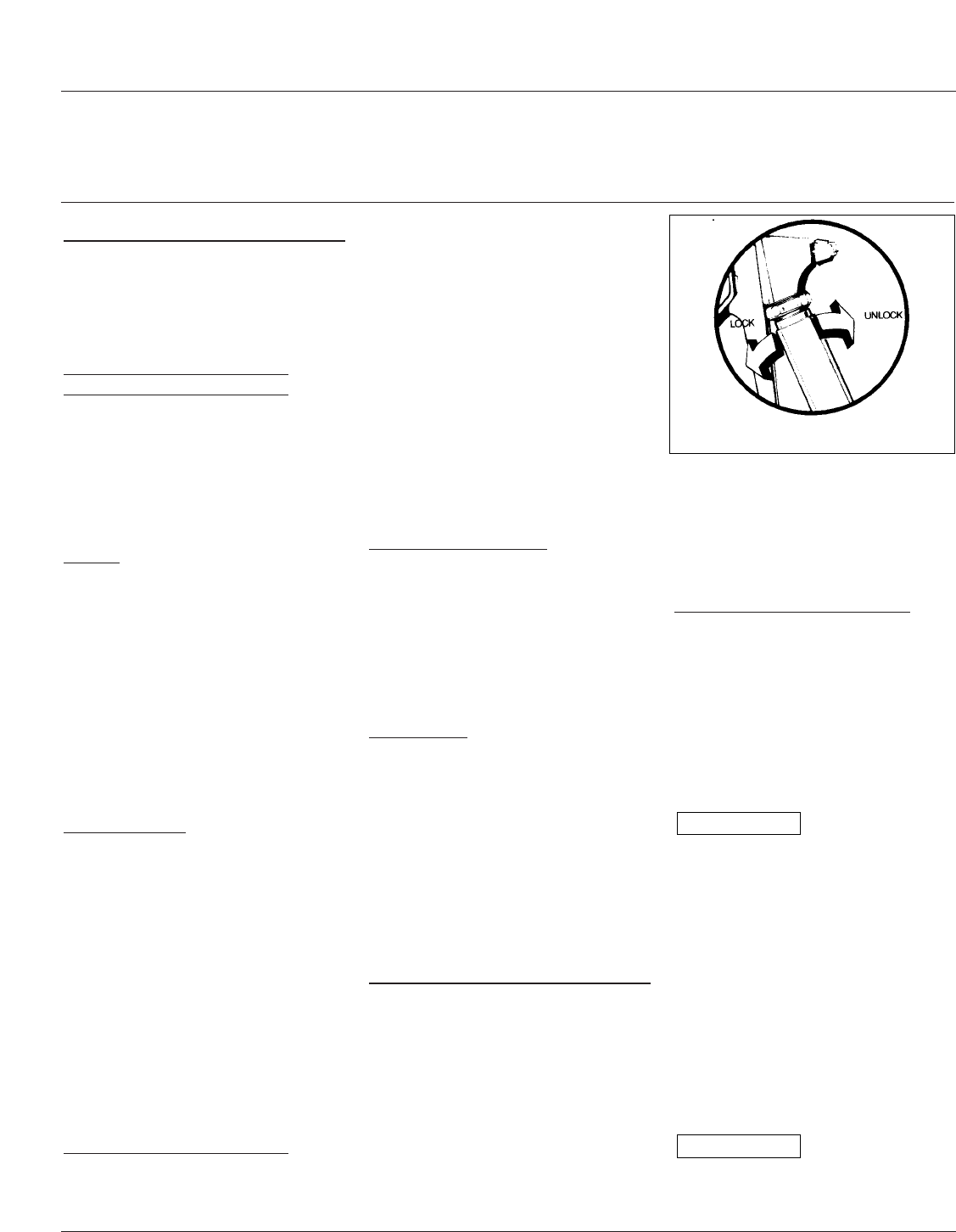

Prior to servicing gun: Attach spray

gun to hose and tighten fittings

securely. Set the gun trigger lock. The

gun trigger lock should always be set

when the gun is not being triggered

(see Figure 10).

Hold gun with trigger locked and push

trigger against the lock . Then adjust

nut so that the retainer will move

freely back and forth approximately

1/32" to allow valve spring unit to seat

the valve ball.

IMPORTANT: Readjust nut periodically

for wear of valve seat and valve ball.

Otherwise, leakage will occur.

REPLACING VALVE BALL HOLDER

Kit #2-007

Parts Needed: 3 Tip Washers, 1 Valve

Seat, 1 Valve Ball Holder, 2 Seals-Teflon

Dismantling:

1. Unscrew rev guard and remove spray

tip and seal.

2. Unscrew valve seat with 1/2" socket

wrench.

When removing and

replacing valve

seat, hold the trigger in the open

position so that the valve ball is lifted

off the valve seat. Failure to life the

ball off the seat will result in a

scrathed, leaky valve.

3. Unscrew valve ball together with the

brass part of the assembly. Do not pull

on the parts or the packing may get

damaged.

4. Unscrew the valve ball from the

brass part of the assembly.

Reassembling is done in reverse

sequence. Screw the new valve ball

with holder into the brass part.

Tighten valve ball

and brass part on

threaded end of the shaft by hand until

you feel a positive stop. Do not tighten

NOTICE

NOTICE

Figure 10 - Setting Trigger Lock

AL2710