Operating Instructions

Welding Guidelines (Continued)

ARC WELDING BASICS

Four basic techniques affect weld quality. These are: amperage

setting, weld angle, arc length, and travel speed. Proper use of

these techniques is necessary for good weld quality.

AMPERAGE SETTING

The correct amperage involves the adjustment of the welding

machine to the required amp setting. This is regulated by a

knob on the welder. The amperage required depends on the size

(diameter) of electrode used and the thickness of the work piece.

Consult specifications listed on the welder. Excessive amps burn

through light metals and the weld bead is flat and porous (See

Figure 4). The bead appears high and irregular if the amperage is

too low.

WELD ANGLE

Weld angle is the angle at which the electrode is held during

the welding process. Using the correct angle ensures proper

penetration and bead formation. Electrode angle involves two

positions - travel angle and work angle (See Figure 5).

Travel angle is the angle in the line of welding and may vary from

5º to 45º from the vertical, depending on welding conditions.

Work angle is the angle from horizontal, measured at right

angles to the line of welding.

For most applications, a 45º travel angle and 45º work angle

is sufficient. For specific applications, consult an arc welding

handbook.

NOTE: Right handed welders should weld from left to right. Left

handed welders should weld from right to left. The electrode

should always point into the weld puddle as shown.

ARC LENGTH

Arc length is the distance from the work piece to the tip of the

electrode, the distance which the arc must travel. A proper

arc length is essential to generate the heat needed for welding

(See Figure 4). An arc that is too long produces an unstable arc,

reduces penetration, increases spatter, and causes flat and wide

beads. Too short an arc does not create enough heat to melt the

work piece, the electrode has a tendency to stick, penetration

will be poor, and uneven beads with irregular ripples result. A

proper arc should be no longer than the diameter of the rod.

The sound of a proper arc is a steady, crisp sizzle, similar to

bacon frying.

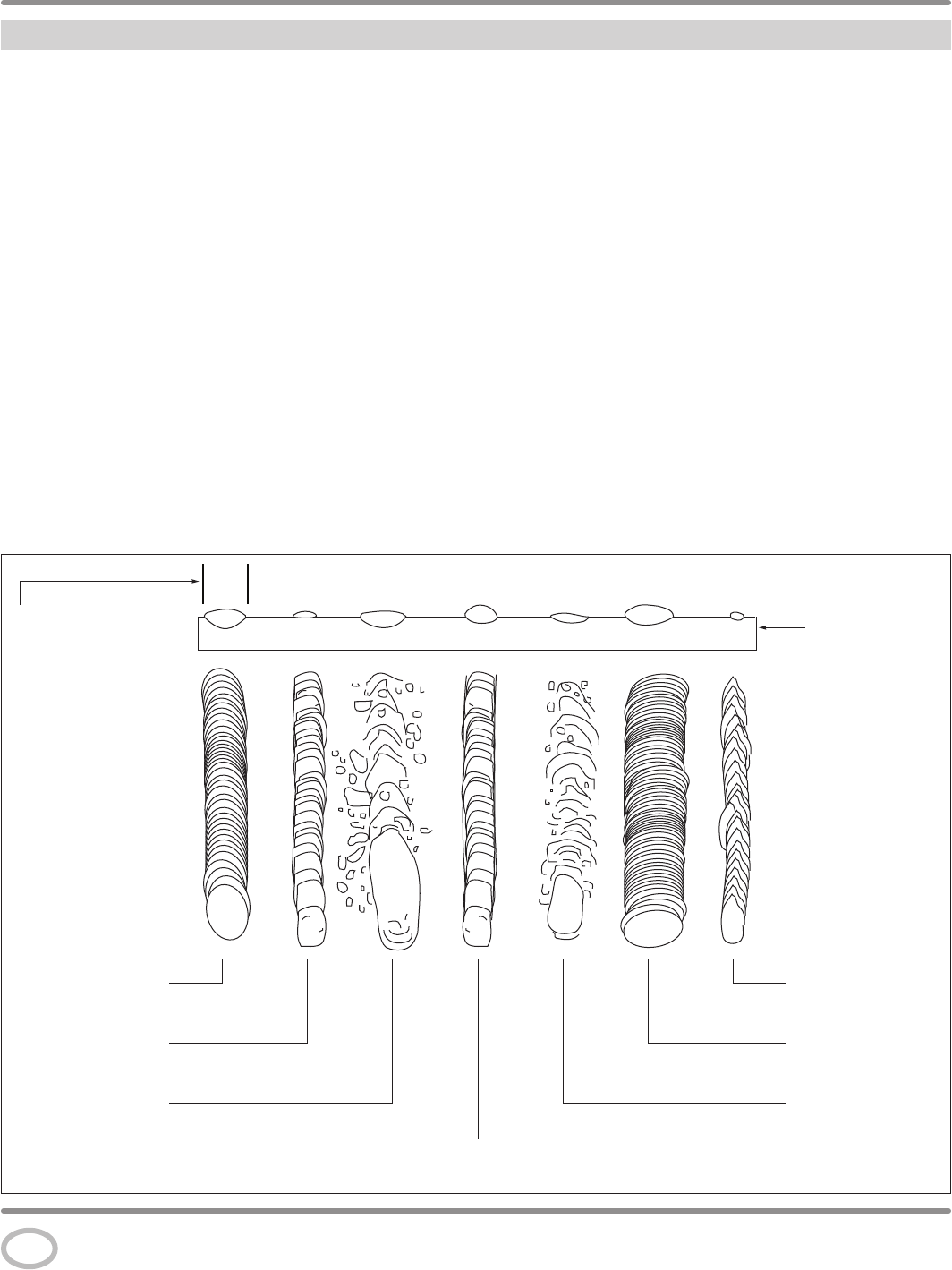

W

Work Piece

Figure 4 - Weld Appearance

NOTE: Weld bead

width (W) should be

approximately twice

the diameter for the

electrode rod used.

Amperage Too Low

Amperage Too High

Arc Length Too Short

Speed Too Fast

Speed Too Slow

Normal Amps,

Arc Length,

Speed

Arc Length Too Long

Work Piece

www.campbellhausfeld.com

14