LOCATION

Selecting the proper location can significantly increase

performance, reliability and life of the unit.

◆ For best results locate the unit in an environment that is

clean and dry. Dust and dirt in the unit retain moisture and

increase wear of moving parts.

◆ There are mounting holes in the bottom of the open frame

models to permanently mount the unit if desired. The bolt

pattern is 20 inch x 26 inch and will accept 1/2 inch bolts.

The wheels (if present) must be removed.

◆ Store electrodes in a clean, dry location with low humidity to

preserve the flux coating.

LUBRICATION

CHECK ENGINE AND PUMP OIL LEVELS

BEFORE OPERATING! Follow lubrication

instructions before operating compressor.

1. Oil is NOT mixed with the gasoline, however adequate

oil supply is necessary for proper engine lubrication.

Refer to the Engine Manual for SAE, API and fill quantity

specifications.

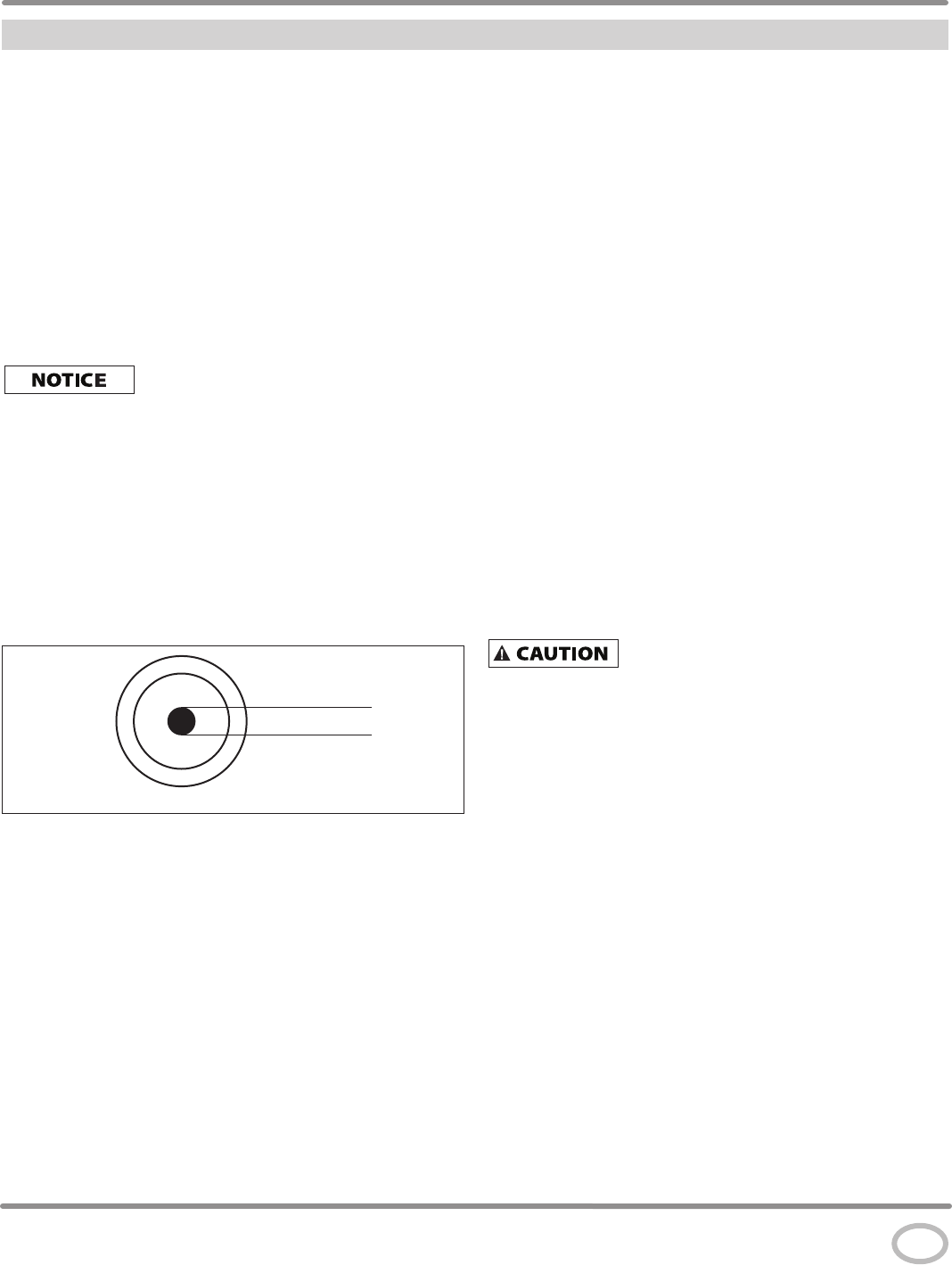

2. Remove pump breather and fill pump with 8.5 oz. of oil. Use

full synthetic motor oil like Mobil 1

®

10W-30. Do not use

regular automotive oil such as 10W-30. Additives in regular

oil can cause valve deposits and reduce pump life. For

pumps with an oil sight glass, oil level can be monitored and

maintained as shown in Figure 1.

GROUNDING

1. Use the ground terminal and wing nut on the frame to

connect the unit to a suitable ground source. Securely fasten

the end terminal of the ground wire to the ground terminal

on the frame. Tighten the washer and wing nut on top of the

ground wire end terminal.

2. The ground wire should be made of #8 gauge wire. Do

not use wire with a higher gauge number. Higher gauge

numbers indicate thinner wire, which may not provide an

adequate ground path.

3. The other end of the ground wire must be securely fastened

to an approved ground source.

The following are ground sources approved by the National

Electric Code. Other ground sources may be acceptable.

Refer to the National Electric Code and local regulations for

further ground source information. If not sure of regulations

or procedures, obtain assistance from a qualified (licensed or

certified) electrical technician.

a. An underground water pipe at least ten feet in length

b. A non-corrosive underground pipe at least eight feet in

length and 3/4 inch diameter

c. A steel or iron underground rod at least eight feet in

length and 5/8 inch diameter

d. A non-ferrous rod at least eight feet in length, 1/2 inch in

diameter, and approved for grounding purposes

Any rod or pipe used for grounding must be driven to eight feet

deep or buried in the deepest possible trench.

STARTING

1. Remove all electrical loads from the unit.

2. Set compressor switch to OFF position.

3. Move fuel shut-off lever as far as possible to the right to

enable fuel flow.

4. Set the engine switch to the RUN position.

5. For a cool engine, pull the choke knob out.

6. Push and hold the START switch until the engine starts,

then release.

7. After each start up, allow the engine to run for 2 to 3

minutes with no load.

8. As the engine warms up and stabilizes, adjust the choke

knob in fully.

Engine speed is preset to provide proper output

voltage. Never attempt to modify or adjust

engine speed or output voltage.

ENGINE BREAK-IN

After initial start-up, the engine should be broken in according

to the manufacturer’s instructions. Refer to the engine manual

for the proper break-in procedure.

COMPRESSOR BREAK-IN

Open the drain valves in the end of the two tanks. Turn the

compressor switch to ON and allow the pump to run without a

load for 30 minutes. After 30 minutes, close the drain petcocks

and pressure will begin to build in the tanks.

SHUT-OFF

1. Shut off and remove all electrical load devices from the unit

2. Set compressor switch to OFF position.

3. Allow the engine to run for

2-3 minutes with no electrical loads.

4. Set the engine switch to the OFF position.

5. Verify that the unit has completely stopped.

6. Close the fuel supply valve.

7. Allow the unit to cool before installing any covers or storing

unit.

GR3000

Pre-Operation

www.campbellhausfeld.com

7

Figure 1

Full

Add Oil