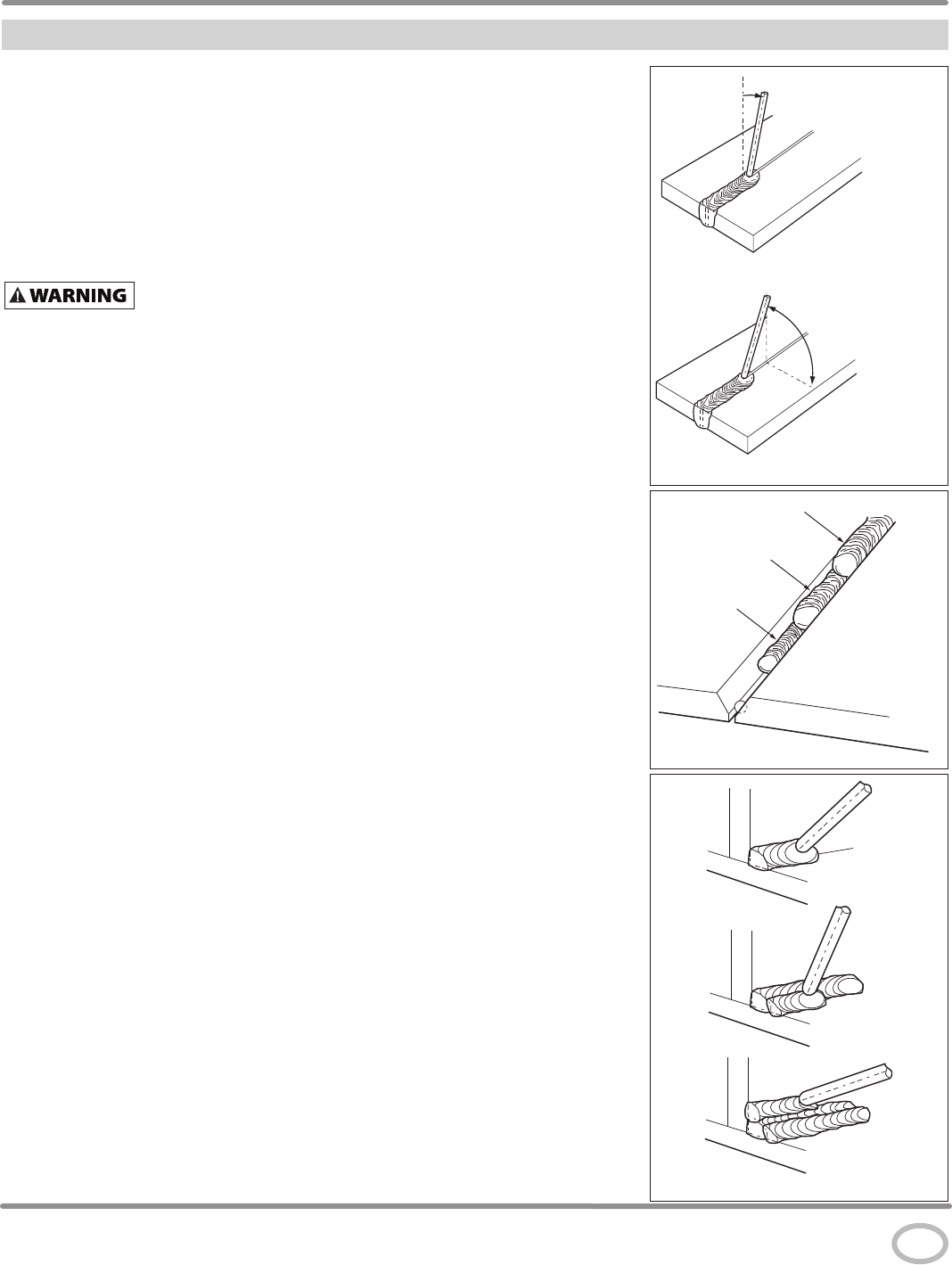

TRAVEL SPEED

The travel speed is the rate at which the electrode is moved across the weld area (See

Figure 4). When the speed is too fast, the bead is narrow and bead ripples are pointed

as shown. When the speed is to slow, the weld metal piles up and the bead is high and

wide. To control travel speed, watch the width of the weld bead (not the arc) when

welding. The weld bead is the orange, molten metal behind the arc. The width should

be approximately twice the diameter of the welding rod. Control travel speed to obtain

a consistent bead width.

SLAG REMOVAL

Wear ANSI compliant safety glasses (ANSI Standard Z87.1) and protective

clothing when removing slag. Hot, flying debris can cause personal injury

to anyone in the area.

After completing the weld, wait for the welded sections to cool. A protective coating

called slag now covers the weld bead which prevents contaminants in the air from

reacting with the molten metal. Once the weld cools to the point that it is no longer

glowing red, the slag can be removed. Removal is done with a chipping hammer.

Lightly tap the slag with the hammer and break it loose from the weld bead. The final

clean-up is done with a wire brush. When making multiple weld passes, remove the

slag before each pass.

WELDING POSITIONS

Four basic welding positions can be used; flat, horizontal, vertical, and overhead.

Welding in the flat position is easier than any of the others because welding speed can

be increased, the molten metal has less tendency to run, better penetration can be

achieved, and the work is less fatiguing.

Other positions require different techniques such as a weaving pass, circular pass, and

jogging. A higher skill level is required to complete these welds.

All work should be performed in the flat position if possible. For specific applications,

consult an arc welding handbook.

WELD PASS

Sometimes more then one pass is necessary to fill the joint. The root pass is first,

followed by filler passes and the cover pass (See Figures 6 and 7). If the pieces are thick,

it may be necessary to bevel the edges that are joined at a 60º angle. Remember to

remove the slag before each pass.

Welding Guidelines (Continued)

www.campbellhausfeld.com

15

5º - 45º

Travel Angle

Work Angle

Figure 5 - Weld Angle

Cover

Filler

Root

Figure 6 - Weld Passes

Figure 7 - Multiple Weld Passes

GR3000