4

Operating Instructions and Parts Manual

HVLP Paint Sprayers

How Your HVLP

System Works

Your turbine system has three

components: the turbine unit, an air

hose and a spray gun. The turbine unit,

when connected to the correct

electrical power supply and powered

on, provides a continuous source of

clean, warm, dry, High Volume Low

Pressure air. The air hose connects the

turbine unit to the spray gun. Air flows

through the hose to the nozzle of the

specially designed spray gun.

Atomization of the coating is achieved

when the air mixes with the stream of

fluid passing through the tip/nozzle.

This low pressure atomization principle

achieves minimum misting (overspray)

to the spray environment.

The turbine blower has one air hose

outlet on the side of the unit and is

designed to run one spray gun. The 4-

stage model has the capability to run

two spray guns at the same time with

an optional “Y” connector. When

using only one spray gun, always be

sure that one outlet is capped.

How Your HVLP

Spray Gun Works

Turbine Spray Guns are bleeder type

spray guns. When the turbine is turned

on, air will constantly flow through the

air cap. This helps makes the

equipment more durable. Air also

flows through the air feed tube in

order to pressurize the cup, and deliver

fluid to the tip/nozzle. When the paint

flow screw is opened and the trigger

pulled back, fluid flows through the

tip/nozzle, mixing with the air flow

delivered from the air cap. The spray

gun projects a fine atomized mist on

your work piece.

www.chpower.com

Pre-Operation

PREPARING TO USE YOUR HVLP

TURBINE SYSTEM

1. Connect the air hose to the turbine.

Pull back the spring loaded quick

disconnect coupler and insert the

male connector on the air hose into

the turbine connector. Release the

ring. Your air hose will be locked

into place. To disconnect, pull back

on the connector to release the air

hose.

If you have just

finished spraying,

the metal coupler at the turbine end

may be hot.

2. Plug the electric cord into a

correctly grounded electrical outlet.

Be sure the electric current is the

correct voltage. If you need to use

an extension cord, be sure it is at

least 12 gauge wire and has a

correctly grounded outlet.

3. Select a safe, well ventilated area

where you will spray your work

piece. Locate your turbine unit

away from the area where you will

be directly spraying. Do not cover

or enclose the turbine. It is

important to draw cool/ambient air

through the unit for optimum

performance. Avoid placing the

!

CAUTION

turbine in a warm environment or

in direct sunlight.

FAMILIARIZING YOURSELF WITH

YOUR SPRAY GUN

HVLP Spray Gun:

1. Slide the lever to one side,

releasing the cup from the holding

pins on the cup. Reverse the

procedure to install the cup onto

the gun body. Make sure the cup is

secure. Be sure the cup is centered

on the gasket under the top of the

cup.

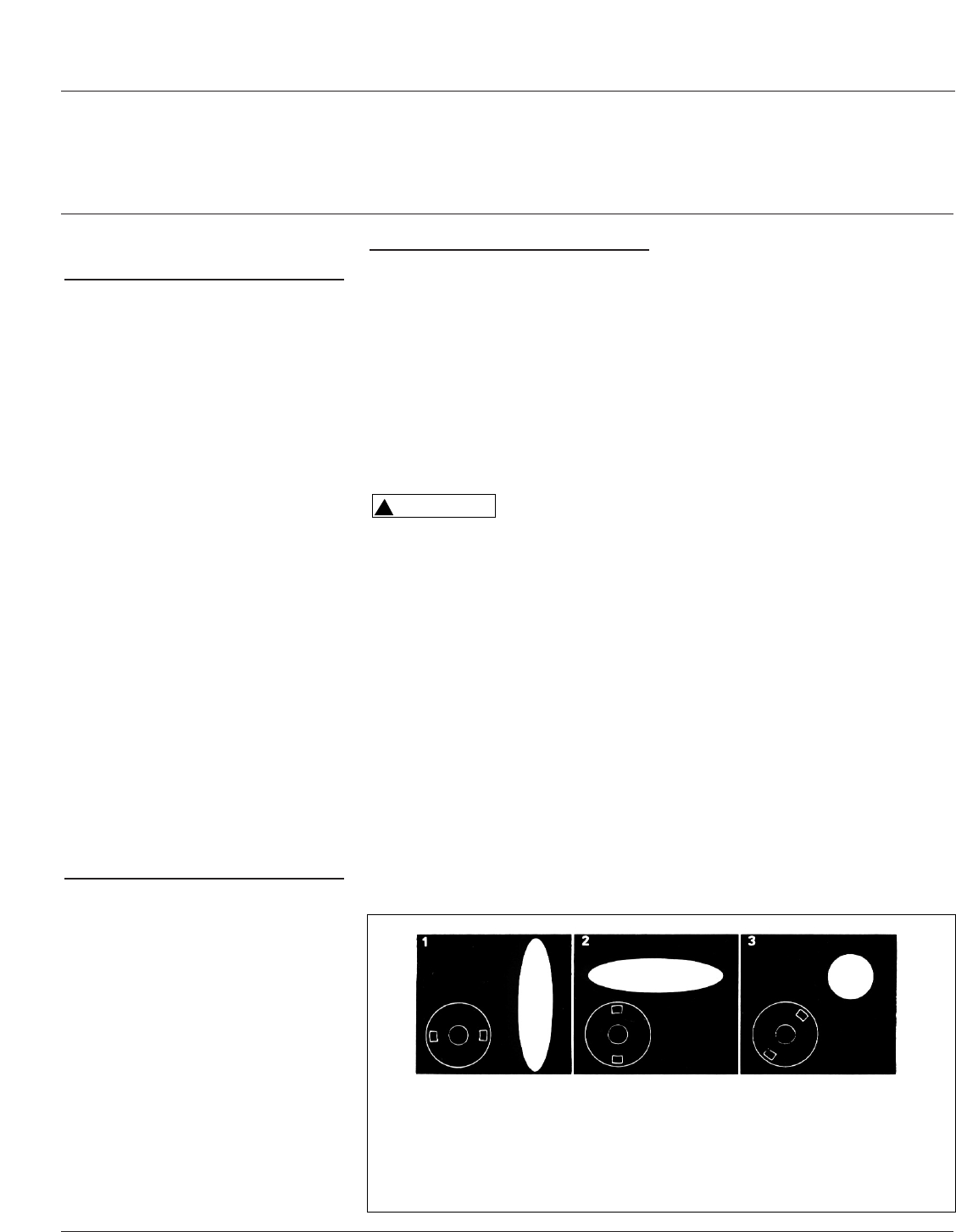

2. Familiarize yourself with the

controls on the spray gun. There

are three main controls: rotating

air cap, material flow knob and air

cap locking ring. Click the rotating

air cap into each position:

horizontal, vertical and 45°. When

the air cap is in the 45° position the

pattern is round. This is useful for

spraying small, narrow pieces of

work. Paint flow will increase when

using the diagonal position. It is

usually necessary to reduce the

paint flow by adjusting the flow

knob. (See Figure 2)

3. Turn the material flow knob

counterclockwise to open or

release more fluid, clockwise to

reduce or close material flow.

HV2100, HV2105

Figure 2 - Material flow knob positions and spray patterns

1. Use this position when spraying across from side to side.

2. Use this position when spraying from top to bottom.

3. Use this position for spotting small objects, corners and sharp angles.