7

HVLP Paint Sprayers

Operating Instructions and Parts Manual

www.chpower.com

HV2100, HV2105

Operation

(Cont.)

13. Pull the trigger. Notice the pattern

has become smaller. (You can

continue reducing the material

flow and move the spray gun even

closer to the surface and the

pattern will keep getting smaller).

14. Rotate the air cap to a diagonal

position (See Figure 2).

15. Every so often, turn the material

flow knob to a different position.

Also, change the distance of the

spray gun from work surface. Notice

how doing this changes pattern size.

There is one additional control to

know. If you loosen the air cap locking

ring, approximately 1-2 turns, you can

control the fan pattern size and trim or

feather the edge of the fan pattern

itself. This should be considered a

secondary control, the primary fan

pattern size being adjusted between

fluid flow and distance of the spray

gun from the work piece.

Even when the turbine is turned off,

pressure will remain in the spray cup.

When trigger is pulled back, a stream

of fluid will flow. To prevent accidents,

turn material flow knob clockwise until

it is completely closed, locking trigger

in closed position.

NOTE: It is not necessary to empty and

clean your spray gun when you pause

between applications. Be sure,

however, to clean your spray gun

thoroughly at the end of your work

session.

Clean spray gun

thoroughly at end

of work session. Do not allow coating

to dry in spray gun overnight or at any

time when not in use.

Extra caution should be taken when

spraying coatings that have a catalyst

or hardener added since many of these

coatings have short pot life. These

NOTICE

!

WARNING

coatings can harden in your spray gun

quickly, making cleaning difficult or

impossible. Read manufacturer’s

coating instructions to help determine

how quickly a particular coating will

harden in your spray gun.

SPRAYING TECHNIQUE

Practice is the key element in achieving

a proper spray technique. Never try to

rush the spray finishing process. Learn

the properties of the coating you will

be spraying. Build up layers of material

(3-4 applications, or more if needed).

Sand between coats, if needed, and

allow proper drying time between

applications.

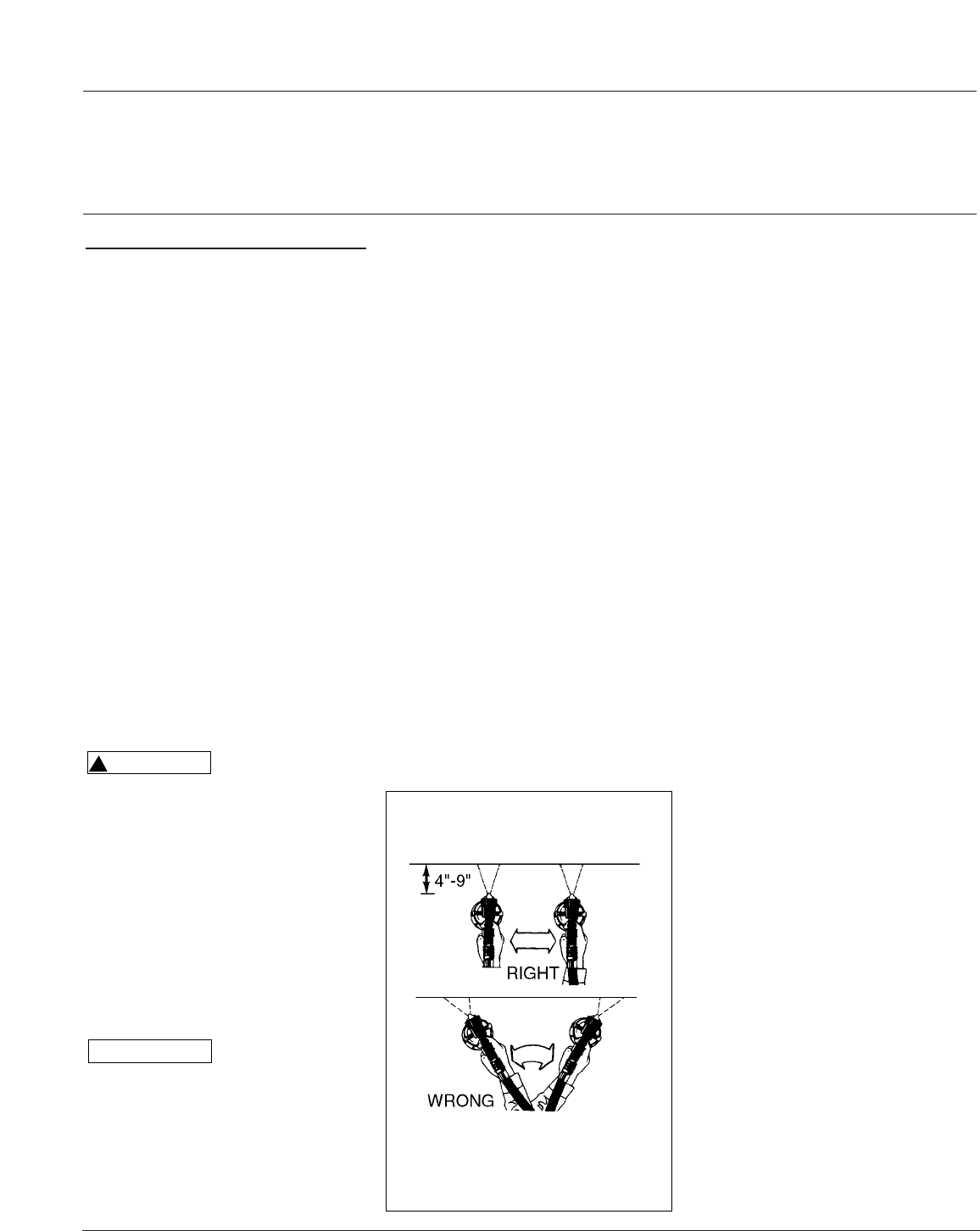

Remember to keep the distance of the

spray gun the same when moving

across your work (called a “pass”). Do

not rotate or turn your wrist from side

to side (See Figure 3). Move the spray

gun across your work from end to end.

Be sure to maintain the same speed of

movement. This will ensure an even

application of coating. Always release

the trigger at the end of a pass.

Continue spraying in the opposite

direction overlapping your previous

coat by 1/3 to 1/2. When finished, you

should have an even wet coat on your

work. If you have dry spots, you have

overlapped too widely.

If you have heavy or wet spots, you

have overlapped too much. When

spraying a large or pre-assembled

piece, start at the top and work down.

Try to spray the hard-to-reach surfaces

first. Keep in mind that a light, wet

film will generally produce better

results than a heavy, wet coat. When

spraying a vertical surface, apply a

thin“tack” coat first, followed by a

normal light wet coat. This technique

will help prevent “runs” and “sags.”

When using your Spray Gun you

control five variables.

1. Fluid flow

2. Distance of the spray gun from

your work. (4"–8" is average. Closer

if necessary.)

3. Pattern Direction (vertical fan,

horizontal fan and round)

4. Speed of application

5. Fan pattern control (adjust air cap

ring)

NOTE: Items 1, 2, and 4 directly relate

to each other.

RUNNING MULTIPLE SPRAY GUNS

WITH A TURBINE

It is possible to run the 4-stage turbine

system with two spray guns at the

same time by installing “Y” Connector

to the turbine outlet port.

IMPORTANT: If the “Y” connector is

installed and only one spray gun

operated, the 2nd outlet must be

capped or closed so that performance

to the single spray gun will not be

affected.

Figure 3 - Proper Spray Technique