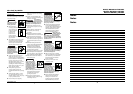

2. Remove cover screw and polarity

cover.

3. Remove four nuts from polarity

studs.

4. Pull out polarity bus bar and rotate

it 90°. Reinsert aligning groove with

the correct rib in polarity box.

Upper right rib marks the MIG

position; lower right rib marks the

Flux position. (See Figure 4c.)

5. Reinstall four nuts and tighten

securely.

6. Reinstall polarity cover and cover

screw.

7. Make sure arrow on polarity cover

points to desired setting.

Assembly (Continued)

POLARITY

MIG welding wire requires electrode

positive electrical polarity. Flux welding

wire requires electrode negative

electrical polarity. The welder is factory

set for flux welding wire.

To Change Polarity

(See Figure 4b)

NOTE: The arrow on the Polarity Cover

points to the current polarity setting.

TOOLS NEEDED: Phillips screwdriver

and 10mm socket wrench.

1. Unplug power cord from socket.

40 Sp

1 Ensamble del soplete y la manguera

(MIG, 2,44 m, WG2060) WC403660AV 1

Ensamble del soplete y la manguera

(MIG, 3,05 m, WG2064) WC404100AV 1

2 Punta de contacto - 0,035” (0,9 mm) WT501400AV 1

Punta de contacto opcional – 0,024”

(0,6 mm) Paq. 4 WT501200AJ †

Punta de contacto opcional – 0,030”

(0,8 mm) Paq. 4 WT501300AJ †

Punta de contacto opcional – 0,035”

(0,9 mm) Paq. 4 WT501400AJ †

3 Boquilla WT502100AV 1

4 Portabobinas WC500805AV 1

5 Ensamble de la placa de conducción WC500800AJ 1

6 Vástago y rejilla WC707018AV 1

7 Retén de la bobina WC707024AV 1

8 Resorte del retén de la bobina WC707026AV 1

9 Anillo del retén de la bobina WC707023AV 1

10 Alambre de soldar con fundente – 0,030”

(0,8 mm) Bobina de 2 lb. (0,9 kg) (E71T-GS) WE200001AV †

Alambre de soldar con fundente – 0,030”

(0,8 mm) Bobina de 10 lb. (4,54 kg) (E71T-GS WE201000AV †

Alambre de soldar con fundente – 0,035”

(0,9 mm) Bobina de 2 lb. (0,9 kg) (E71T-GS) WE200501AV †

Alambre de soldar con fundente – 0,035”

(0,9 mm) Bobina de 10 lb. (4,54 kg) (E71T-GS) WE201500AV †

Alambre de soldar MIG – 0,024”

(0,6 mm) Bobina de 2 lb (0,9 kg) (ER70S6) WE300001AV †

Alambre de soldar MIG – 0,024”

(0,6 mm) Bobina de 11 lb. (5 kg) (ER70S6) WE301500AV †

No de No De

Ref. Descripción Componente Cant

Modelos WG2060 y WG2064

Alambre de soldar MIG – 0,030” (0,8 mm)

Bobina de 2 lb. (0,9 kg) (ER70S6) WE300501AV †

Alambre de soldar MIG – 0,030” (0,8 mm)

Bobina de 11 lb. (5 kg) (ER70S6) WE302000AV †

Alambre de soldar MIG – 0,035” (0,9 mm)

Bobina de 2 lb. (0,9 kg) (ER70S6) WE301001AV †

Alambre de soldar MIG – 0,035” (0,9 mm)

Bobina de 11 lb. (5 kg) (ER70S6) WE302500AV †

Alambre de soldar MIG – 0,030” (0,8 mm)

1 lb (0,45 kg) de aluminio (ER5356) WE303001AV †

11Retén del recipiente con 4 tornillos WC302600AJ 1

12 Conexión dentada de la manguera

(externa) WC403900AV 1

▲ Accesorio de conexión rápida

(interna) WC403901AV 1

13▲ Manguera de gas – 22” (56 cm) WC403902AV 1

14▲ Abrazadera de la manguera WC403903AV 2

15▲ Regulador (WG2060) WC803500AV 1

▲ Regulador (WG2064) WC803600AV 1

16▲ Máscara de mano

(no se incluyen lentes) WC801700AV 1

17▲ Lentes oscuros

(para máscara de mano) WC801100AV 1

18▲ Martillo/cepillo cincelador WC803400AV 1

19▲ Etiqueta adhesiva de seguridad DK688509AV 1

20▲ Juego de la barra de polaridad WC403128AV 1

21 ▲ Pinza de tierra (WG2060) WC100300AV 1

▲ Pinza de tierra (WG2064) WC100600AV 1

22 ▲ Guantes para soldar (sólo WG2064) WT200501AV 1

▲ No se muestra

† Accesorio opcional

No de No De

Ref. Descripción Componente Cant

Soldadora Por Arco Con Alimentación de Cable

3

4

1

8

9

2

11

10

7

12

6

5

Figura 14 - Piezas de Repuesto

Para Ordenar Repuestos o

Asistencia Técnica, Sírvase Llamar

al Distribuidor Más Cercano a Su

Domicilio

Dirija toda la correspondencia a:

Campbell Hausfeld

Attn: Customer Service

100 Mundy Memorial Drive

Mt. Juliet, TN 37122 U.S.A.

Sírvase suministrarnos la siguiente información:

- Número del modelo

- Número de Serie (de haberlo)

- Descripción y número del repuesto según la

lista de repuestos

Shielding Gas Preparation

Improper handling

and maintenance of

compressed gas cylinders and regulators

can result in serious injury or death!

Always secure gas cylinders to tank

bracket kit, a wall or other fixed support

to prevent cylinder from falling over.

Read, understand and follow all

compressed gas and equipment

warnings in the safety instructions.

NOTE: Shielding gas is not required if

flux-core welding wire is used.

GAS TYPES

There are 3 types of gas generally used

for gas metal arc welding; 100% argon,

a mixture of 75% argon and 25%

carbon dioxide (C25) or 100% carbon

dioxide.

Use ONLY the type

of gas recommended

for your welder. Use ONLY an inert, non-

flammable type of gas. Failure to do so

will result in a very hazardous situation.

NOTE: 100% carbon dioxide is not

recommended due to unsatisfactory

weld beads.

The 75/25 mixture is recommended for

general steel welding. For aluminum

welding, use 100% argon. Cylinders of

either type gas may be obtained at your

local welding supply outlet. Secure

cylinder in place on your welding

machine or other support to prevent the

cylinder from falling over.

Obtaining Correct Gas Type. The gas

used in any welding application for your

welder must be an INERT, NON-

FLAMMABLE TYPE. You can get the type

of gas needed from a nearby welding

gas distributor (often found in the

yellow pages under “Welders” or

‘Welding Equipment”).

REGULATOR

An adjustable regulator without gauges

is supplied with the WG2060. The

regulator supplied with the WG2064

includes two gauges. The regulator

provides a constant shielding gas pressure

and flow rate during the welding process.

Each regulator is designed to be used

with a specific gas or mixture of gases.

The argon and argon mixture use the

same thread type. The 100% carbon

dioxide uses a different thread type. An

adapter is available at your local welding

gas supplier to change between the two.

!

DANGE

R

!

DANGER

5

Models WG2060 and WG2064

www.chpower.com

Contact Tip Markings

Mark Wire Size

0.6 mm .024"

0.8 mm .030”

0.9 mm .035”

Torch Diffuser

Contact Tip

Nozzle

Figure 4 - Torch Nozzle

Figure 4b

Polarity box

Flux rib

Polarity bus bar

Nuts

Cover screw

Polarity

cover

Groove

Polarity studs

MIG rib

Figure 4c

MIG position

Flux position

Upper right—

MIG rib

Lower right—

Flux rib