18

START-UP

Use the following information and Start-Up Checklist on

page CL-1 to check out unit PRIOR to start-up.

Unit Preparation —

Check that unit has been installed in

accordance with these installation instructions and all applica-

ble codes.

Internal Wiring —

Check all electrical connections in

unit control boxes; tighten as required.

Crankcase Heater (Size 028 and Units with

MoistureMiser Dehumidification Package

Only) —

Heater is energized as long as there is power to unit

and compressor is not operating.

Compressor Mounting —

Compressors are internally

spring mounted. Do not loosen or remove compressor hold-

down bolts.

Refrigerant Service Ports —

Each refrigerant sys-

tem has a total of 3 Schrader-type service gage ports. One port

is located on the suction line, one on the compressor

discharge

line, and one on the liquid line. In addition Schrader-type

valves are located underneath the low-pressure switches. Be

sure that caps on the ports are tight.

Compressor Rotation —

It is important to be certain

the compressors are rotating in the proper direction. To deter-

mine whether or not compressors are rotating in the proper di-

rection:

1. Connect service gages to suction and discharge pressure

fittings.

2. Energize the compressor.

3. The suction pressure should drop and the discharge pres-

sure should rise, as is normal on any start-up.

If the suction pressure does not drop and the discharge pres-

sure does not rise to normal levels:

1. Note that the evaporator fan is probably also rotating in

the wrong direction.

2. Turn off power to the unit.

3. Reverse any two of the incoming power leads.

4. Turn on power to the compressor.

The suction and discharge pressure levels should now move

to their normal start-up levels.

NOTE: When compressors are rotating in the wrong direction,

the unit will have increased noise levels and will not provide

heating and cooling.

After a few minutes of reverse operation, the scroll com-

pressor internal overload protection will open, which will acti-

vate the unit’s lockout and requires a manual reset. Reset is ac-

complished by turning the thermostat on and off.

Evaporator Fan —

Fan belt and variable pulleys are fac-

tory installed. Remove tape from the fan pulley. See Table 7 for

Air Quantity Limits. See Tables 8-10 for Fan Performance

data. Be sure that fans rotate in the proper direction. See

Tables 11-13 for Static Pressure information for accessories

and options. See Table 14 for fan rpm at various fan motor pul-

ley settings. To alter fan performance, see Evaporator-Fan Per-

formance Adjustment section, page 25.

Table 7 — Air Quantity Limits

Condenser Fans and Motors —

Fans and motors

are factory set. Refer to Condenser-Fan Adjustment section

(page 26) as required.

Return-Air Filters —

Check that correct filters are in-

stalled in filter tracks. See Table 1. Do not operate unit without

return-air filters.

Outdoor-Air Inlet Screens —

Outdoor-air inlet screens

must be in place before operating unit.

Accessory EconoMi$er Adjustment —

Remove fil-

ter access panel. Check that outdoor-air damper blades are

closed and return-air damper blades are open.

EconoMi$er operation and adjustment is described in Base

Unit Operation and EconoMi$er Adjustment sections

(pages 23 and 27), respectively.

IMPORTANT: Unit power must be on for 24 hours prior

to start-up. Otherwise, damage to compressor may

result.

UNIT

50TJ

MINIMUM CFM MAXIMUM CFM

016

4500 7,500

020

5400 9,000

024

6000 10,000

028

7000 11,250

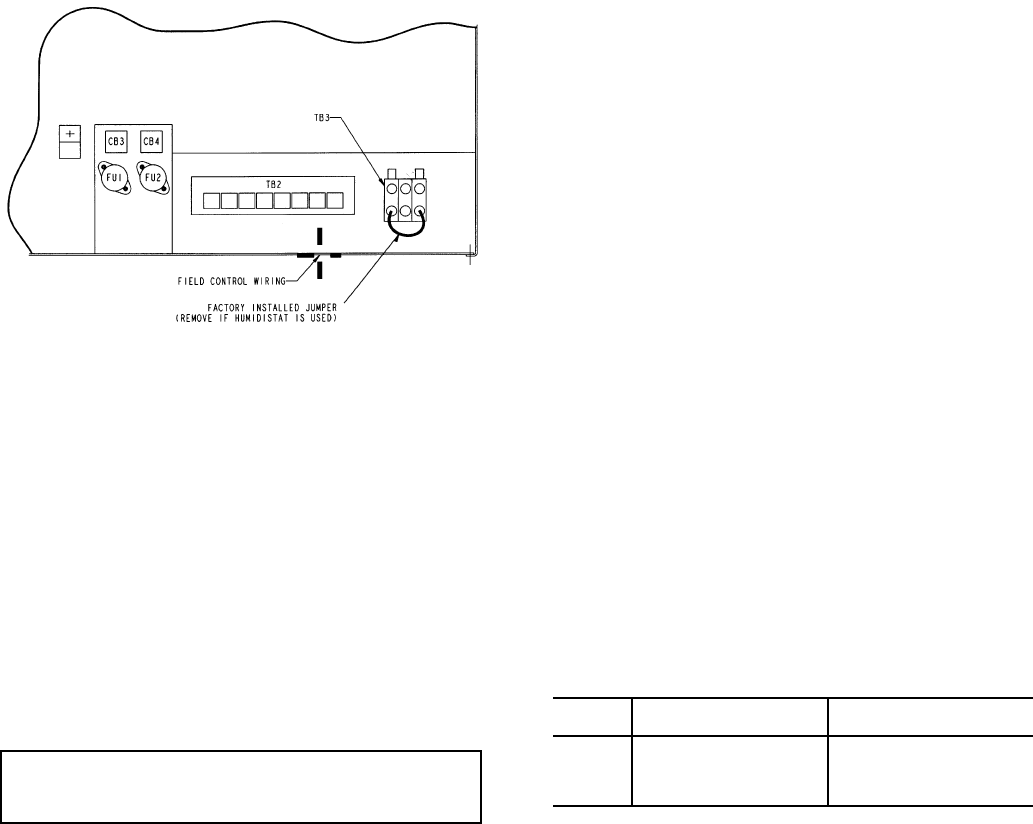

Fig. 29 — Typical MoistureMiser Dehumidification

Package Control Box