28

MOISTUREMISER SYSTEM CHARGING — The system

charge for units with the MoistureMiser option is greater than

that of the standard unit alone. The charge for units with this

option is indicated on the unit nameplate drawing. To charge

systems using the MoistureMiser Dehumidification package,

fully evacuate, recover, and re-charge the system to the name-

plate specified charge level. To check or adjust refrigerant

charge on systems using the MoistureMiser Dehumidification

package, charge per the standard subcooling charts. The sub-

cooler MUST be deenergized to use the charging charts. The

charts reference a liquid pressure (psig) and temperature at a

point between the condenser coil and the subcooler coil. A tap

is provided on the unit to measure liquid pressure entering the

subcooler (leaving the condenser).

Filter Drier —

Replace whenever refrigerant system is ex-

posed to atmosphere.

Protective Devices

COMPRESSOR PROTECTION

Overcurrent

— Each compressor has internal line break motor

protection, except the circuit no. 1 on the 50TJ028 unit. Com-

pressor no. 1 on the 50TJ028 unit uses an electronic module lo-

cated with the compressor junction box, to provide motor pro-

tection. This electronic module monitors winding and dis-

charge temperatures. If these temperatures reach the trip

values, the module interrupts the control line and causes the

compressor to switch off.

Crankcase Heater

— Only the 50TJ028 unit and units with

the optional MoistureMiser Dehumidification system are

equipped with a 70-watt crankcase heater to prevent absorption

of liquid refrigerant by oil in the crankcase when the compres-

sor is idle. The crankcase heater is energized whenever there is

a main power to the unit and the compressor is not energized.

Compressor Lockout

— If any of the safeties (high-pressure,

low-pressure, freeze protection thermostat, compressor internal

thermostat) trip, or if there is loss of power to the compressors,

the CLO (compressor lockout) will lock the compressors off.

To reset, manually move the thermostat setting.

EVAPORATOR FAN MOTOR PROTECTION — A manu-

al reset, calibrated trip, magnetic circuit breaker protects

against overcurrent. Do not bypass connections or increase the

size of the breaker to correct trouble. Determine the cause and

correct it before resetting the breaker.

CONDENSER-FAN MOTOR PROTECTION — Each

condenser-fan motor is internally protected against

overtemperature.

HIGH- AND LOW-PRESSURE SWITCHES — If either

switch trips, or if the compressor overtemperature switch acti-

vates, that refrigerant circuit will be automatically locked out

by the CLO. To reset, manually move the thermostat setting.

FREEZE PROTECTION THERMOSTAT (FPT) — An FPT

is located on the top and bottom of the evaporator coil. It de-

tects frost build-up and turns off the compressor, allowing the

coil to clear. Once the frost has melted, the compressor can be

reenergized.

Relief Devices —

All units have relief devices to protect

against damage from excessive pressures (e.g., fire). These de-

vices protect the high and low side.

Control Circuit, 24-V —

This control circuit is protect-

ed against overcurrent by a 3.2-amp circuit breaker. Breaker

can be reset. If it trips, determine cause of trouble before

resetting.

Replacement Parts —

A complete list of replacement

parts may be obtained from any Carrier distributor upon

request.

EconoMi$er LEDs —

The EconoMi$er control module

has an LED for diagnostic purposes. The flash code identifica-

tion is shown in Table 15.

Optional Hinged Access Doors —

When the optional

service package is ordered or the if the hinged access doors

option is ordered, the unit will be provided with external and

internal hinged access doors to facilitate service.

Four external hinged access doors are provided. All external

doors are provided with 2 large

1

/

4

turn latches with folding

bail-type handles. (Compressor access doors have one latch.) A

single door is provided for filter and drive access. One door is

provided for control box access. The control box access door is

interlocked with the non-fused disconnect which must be in the

OFF position to open the door. Two doors are provided for ac-

cess to the compressor compartment.

Two internal access doors are provided inside the filter/

drive access door. The filter access door (on the left) is secured

by 2 small

1

/

4

turn latches with folding bail-type handles. This

door must be opened prior to opening the drive access door.

The drive access door is shipped with 2 sheet metal screws

holding the door closed. Upon initial opening of the door, these

screws may be removed and discarded. The door is then held

shut by the filter access door, which closes over it.

IMPORTANT: After prolonged shutdown or servicing,

energize the crankcase heaters for 24 hours before start-

ing the compressors.

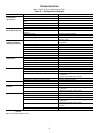

50

40

100

150

200

250

300

350

400

60

80

100

120

140

ALL OUTDOOR FANS MUST BE OPERATING

LIQUID PRESSURE AT LIQUID VALVE (PSIG)

LIQUID TEMPERATURE AT LIQUID VALVE (DEG F)

BOTH CIRCUITS

REDUCE CHARGE IF BELOW CURVE

ADD CHARGE IF ABOVE CURVE

Fig. 36 — Cooling Charging Chart