27

EconoMi$er Adjustment

LED INDICATION — The EconoMi$er controller features

an onboard diagnostic LED (light-emitting diode) that flashes

to indicate its status. See Table 15 for flash codes. The control-

ler also has terminal connections (REM LED) for remotely

mounting an LED, if desired. The flash code priorities are as

follows:

1. On/Off or continuous flash

2. Critical fault

3. Non-critical fault

If any sensors are opened, shorted, or removed, the

EconoMi$er determines whether the failure is critical or non-

critical and flashes the appropriate code. If a non-critical sensor

fault occurs (i.e., outdoor air humidity), the EconoMi$er auto-

matically reconfigures its control strategy to a more appropriate

mode. If a critical sensor fault occurs (i.e., supply air sensor),

the EconoMi$er reverts to a safe mode of operation until the

sensor problem is resolved.

MANUAL CONFIGURATION PUSHBUTTON — The

EconoMi$er controller also features an onboard button (CON-

FIG) to help troubleshoot the system. See Fig. 16. The button

can perform 3 different functions.

Pressing the CONFIG button for more than three seconds,

but less than ten seconds and then releasing will start the auto-

matic test procedure. The damper will modulate fully open,

wait, and modulate closed. This process takes three minutes to

complete. Use this feature to determine if the actuator can be

commanded.

If the CONFIG button is pressed and held for ten seconds

and less than 30 seconds then released, the EconoMi$er con-

troller reconfigures its mode of operation based on the sensors

that are connected and functioning normally, and cancels the

automatic test procedure.

If the EconoMi$er controller recognized a non-critical

sensor fault, and flashed a code (i.e., FLASH 6, outdoor air

humidity sensor fault) the FLASH CODE will be cleared, and

normal operation begins. Ensure faulty sensor is removed

before clearing faults.

If the EconoMi$er controller recognizes a critical sensor

fault, and flashes a code (i.e., FLASH 4, discharge air thermo-

stat fault) the FLASH code will not be cleared, and the

EconoMi$er will remain in the safe operation mode. The

sensor fault must be corrected to enable EconoMi$er to revert

to normal operation.

If the CONFIG button is pressed and held for more than

30 seconds and released, the EconoMi$er controller will enable

the enthalpy comparison strategy (with outdoor air enthalpy

and return air enthalpy sensors installed).

Power Failure —

Dampers have a spring return. In event

of power failure, dampers will return to fully closed position

until power is restored.

Do not manually operate damper

motor.

Refrigerant Charge —

Amount of refrigerant charge is

listed on unit nameplate and in Table 1. Refer to Carrier GTAC

II; Module 5; Charging, Recovery, Recycling, and Reclamation

section for charging methods and procedures. Unit panels must

be in place when unit is operating during charging procedure.

NOTE: Do not use recycled refrigerant as it may contain con-

taminants.

NO CHARGE — Use standard evacuating techniques. After

evacuating system, weigh in the specified amount of refriger-

ant (refer to Table 1).

LOW CHARGE COOLING — Using cooling charging chart

(see Fig. 36), add or remove refrigerant until conditions of the

chart are met. Note that charging chart is different from those

normally used. An accurate pressure gage and temperature-

sensing device is required. Charging is accomplished by ensur-

ing the proper amount of liquid subcooling. Measure liquid line

pressure at the liquid line service valve using pressure gage.

Connect temperature sensing device to the liquid line near the

liquid line service valve and insulate it so that outdoor ambient

temperature does not affect reading.

TO USE THE COOLING CHARGING CHART — Use the

above temperature and pressure readings, and find the intersec-

tion point on the cooling charging chart. If intersection point on

chart is above line, add refrigerant. If intersection point on

chart is below line, carefully recover some of the charge. Re-

check suction pressure as charge is adjusted. NOTE: Indoor-air

CFM must be within normal operating range of unit. All out-

door fans must be operating.

The TXV (thermostatic expansion valve) is set to maintain

between 15 and 20 degrees of superheat at the compressors.

The valves are factory set and should not require re-adjustment.

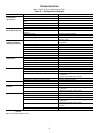

Table 15 — EconoMi$er Control Module Flash Code Identification

FLASH CODE CAUSE ACTION TAKEN BY ECONOMI$ER

Constant On

Normal operation Normal operation.

Constant Off

No power No operation.

Continuous

Flash

CONFIG button pushed and held

between 3 and 9 seconds

Outdoor air damper is stroked fully open, then closed

(automatic test procedure takes 3 minutes to complete).

Critical Fault

Flash One

Control board fault System shutdown.

Flash Two

Thermostat fault (i.e., Y2 without Y1) System shutdown until corrected.

Flash Three

Actuator fault Revert to mechanical cooling only.

Flash Four

Discharge air thermistor fault

Continue operation with damper at minimum position.

Revert to mechanical cooling only.

Flash Five

Outdoor air temperature sensor fault

Continue operation with damper at minimum position.

Disable mechanical cooling lockout.

Non-Critical Fault

Flash Six

Outdoor air humidity sensor fault Continue operation with dry bulb or dry bulb differential switchover.

Flash Seven

Return air temperature sensor fault

Continue operation with single enthalpy EconoMi$er

switchover or dry bulb EconoMi$er switchover (without

humidity sensor).

Flash Eight

Return air humidity sensor fault

Continue operation with single enthalpy, differential dry

bulb, or dry bulb EconoMi$er switchover.

Flash Nine

Carbon Dioxide (CO

2

) sensor fault Continue operation without ventilation control.

Flash Ten

Onboard adjustment potentiometer fault Continue operation with default potentiometer settings.