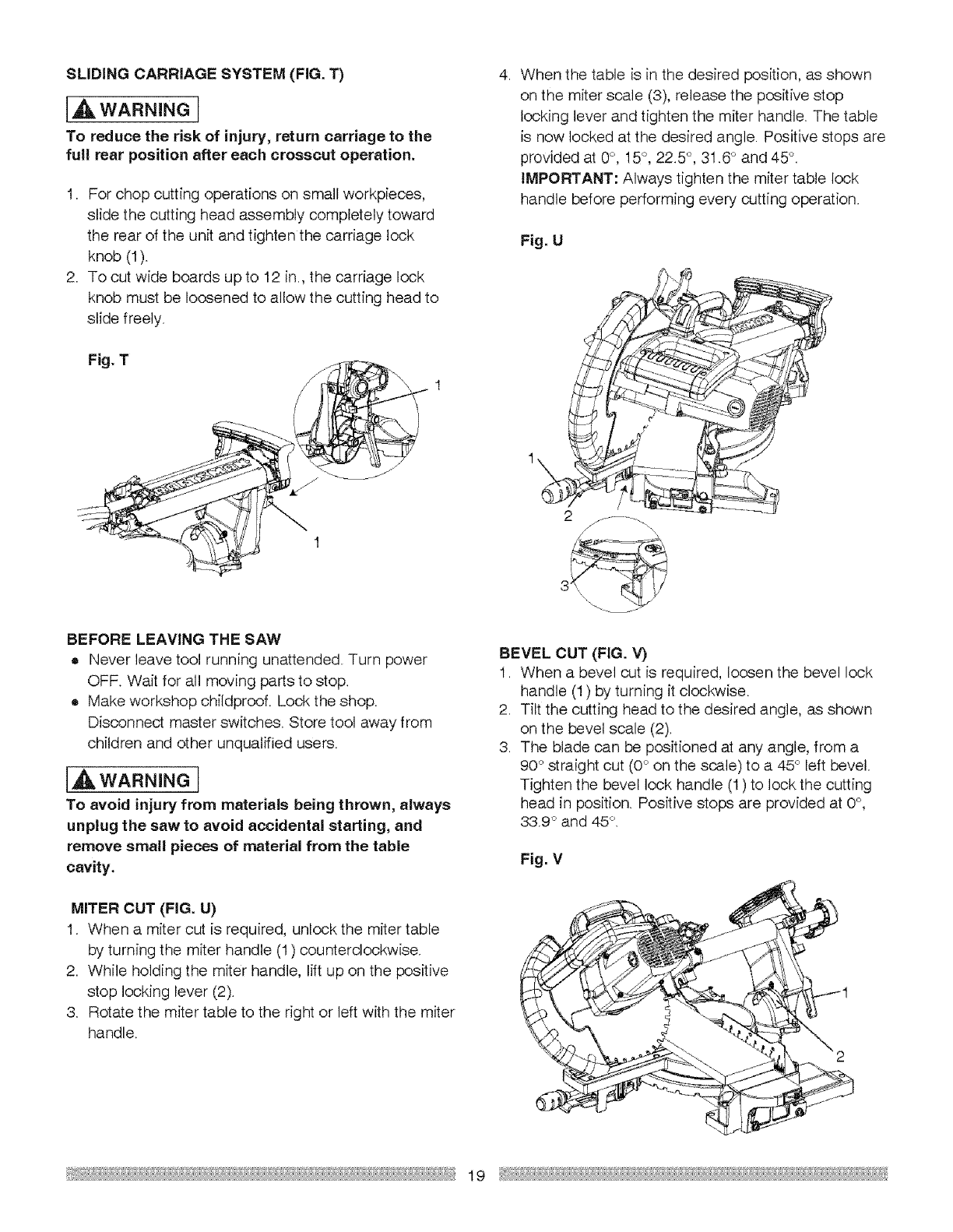

SLIDING CARRIAGE SYSTEM (FIG. 1")

[A WARNINGI

To reduce the risk of injury, return carriage to the

full rear position after each crosscut operation.

I. For chop cutting operations on small workpieces,

slide the cutting head assembly completely toward

the rear of the unit and tighten the carriage lock

knob (1).

2. To cut wide boards up to 12 in., the carriage lock

knob must be loosened to allow the cutting head to

slide freely.

Fig. T

When the table is in the desired position, as shown

on the miter scale (3), release the positive stop

locking lever and tighten the miter handle. The table

is now locked at the desired angle. Positive stops are

provided at 0°, 15°, 225 °, 31.6 ° and 45°.

IMPORTANT: Always tighten the miter table lock

handle before performing every cutting operation.

Fig. U

BEFORE LEAVING THE SAW

, Never leave tool running unattended. Turn power

OFF. Wait for all moving parts to stop.

® Make workshop childproof. Lock the shop.

Disconnect master switches. Store tool away from

children and other unqualified users.

[A wAR.mr,JGI

To avoid injury from materials being thrown, always

unplug the saw to avoid accidental starting, and

remove small pieces of material from the table

cavity.

MITER CUT (FIG. U)

I. When a miter cut is required, unlock the miter table

by turning the miter handle (1) counterclockwise.

2. While holding the miter handle, lift up on the positive

stop locking lever (2).

3. Rotate the miter table to the right or left with the miter

handle.

BEVEL CUT (FIG. V)

1. When a bevel cut is required, loosen the bevel lock

handle (1) by turning it clockwise.

2. Tilt the cutting head to the desired angle, as shown

on the bevel scale (2).

3. The blade can be positioned at any angle, from a

90° straight cut (0° on the scale) to a 45 ° left bevel.

Tighten the bevel lock handle (1) to lock the cutting

head in position. Positive stops are provided at 0°,

33.9° and 45 °1

Fig. V

19