NOTE:Thesawcomeswitha33.9°crownmolding

stop.

33.9° BEVEL STOP FOR CROWN MOLDING (FIG. W)

I. Push the bevel detent stop pin (2) in toward the front

of the machine.

2. Loosen the bevel lock handle (1).

3. Rotate the cutting head until the bevel detent pin

stops the bevel angle at 33.9 c'on the bevel scale.

4. Tighten the bevel lock handle before making a cut.

Fig. W

COMPOUND CUT (FIG. X)

A compound cut is the combination of a miter and a

bevel cut simultaneously,

I. Loosen the bevel lock handle (1) and position the

cutting head at the desired bevel position. Lock the

bevel lock handle.

2. Loosen the miter handle (2). Press down the positive

stop locking lever (3) and position the table at the

desired angle. Release the positive stop locking lever

and lock the miter handle.

Fig. X

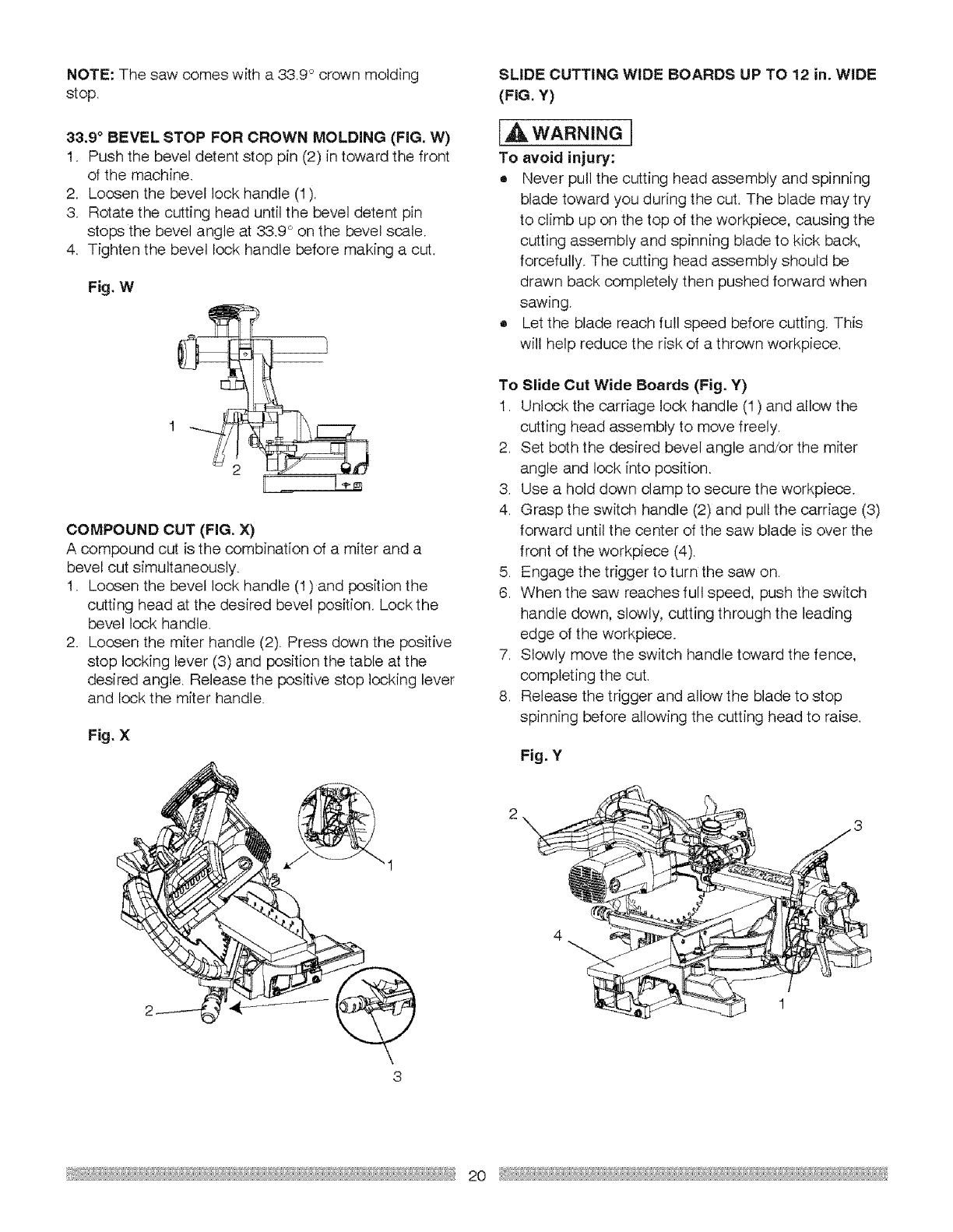

SLIDE CUTTING WIDE BOARDS UP TO 12 in. WIDE

(FIG. Y)

IAWA"Ni"GI

To avoid injury:

• Never pull the cutting head assembly and spinning

blade toward you during the cut. The blade may try

to climb up on the top of the workpiece, causing the

cutting assembly and spinning blade to kick back,

forcefully. The cutting head assembly should be

drawn back completely then pushed forward when

sawing

• Let the blade reach full speed before cutting. This

will help reduce the risk of a thrown workpiece.

To Slide Cut Wide Boards (Fig. Y)

1. Unlock the carriage lock handle (I) and allow the

cutting head assembly to move freely.

2. Set both the desired bevel angle and/or the miter

angle and lock into position.

3. Use a hold down clamp to secure the workpiece.

4. Grasp the switch handle (2) and pull the carriage (3)

forward until the center of the saw blade is over the

front of the workpiece (4).

5. Engage the trigger to turn the saw on.

6. When the saw reaches full speed, push the switch

handle down, slowly, cutting through the leading

edge of the workpiece.

7. Slowly move the switch handle toward the fence,

completing the cut.

8. Release the trigger and allow the blade to stop

spinning before allowing the cutting head to raise.

Fig, Y

2O