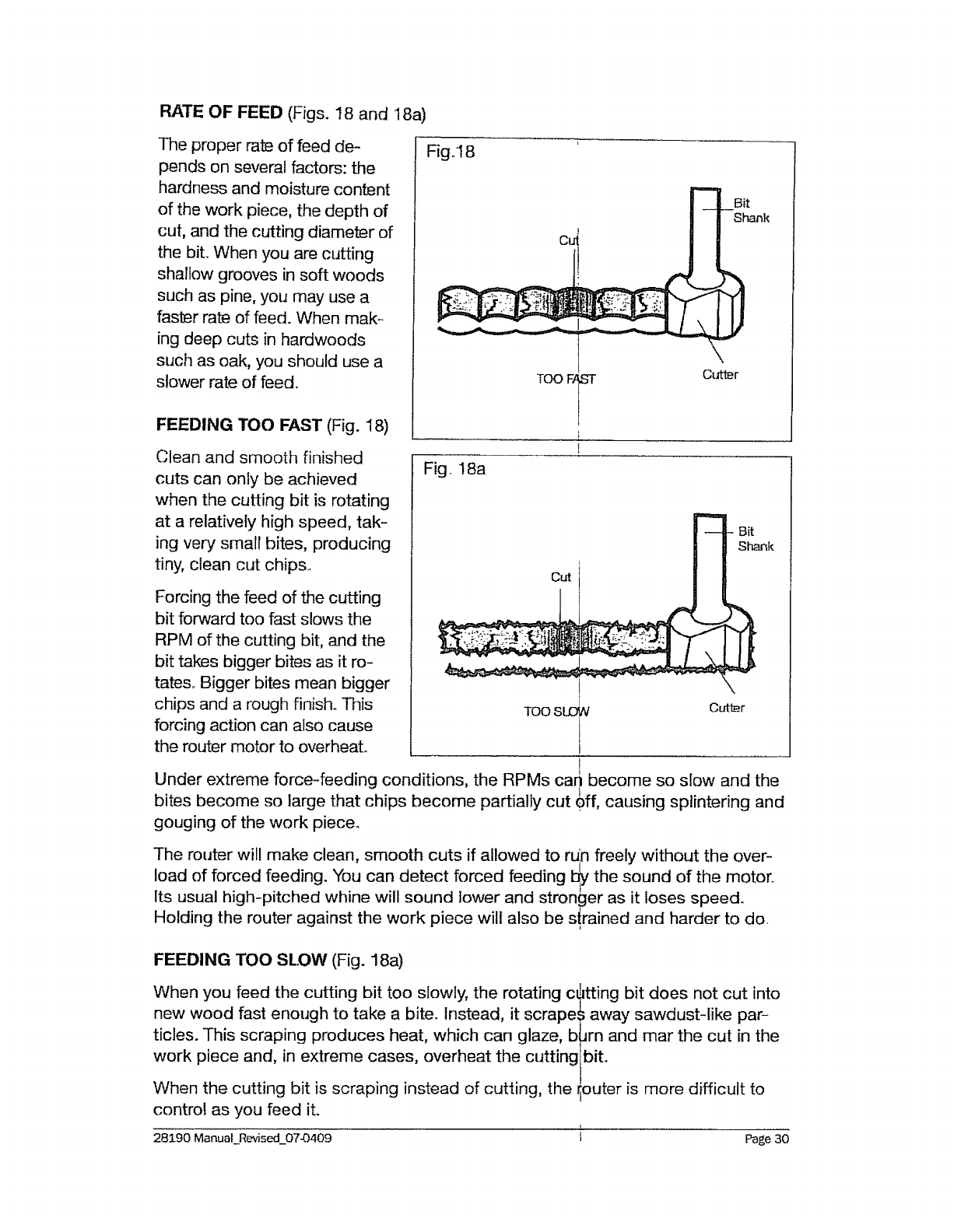

RATE OF FEED (Figs. 18 and '18a)

The proper rate of feed de-

pends on several factors: the

hardness and moisture content

of the work piece, the depth of

cut, and the cutting diameter of

the bit. When you are cutting

shallow grooves in soft woods

such as pine, you may use a

faster rate of feed. When mak-

ing deep cuts in hardwoods

such as oak, you should use a

slower rate of feed.

FEEDING TOO FAST (Fig. 18)

Clean and smooth finished

cuts can only be achieved

when the cutting bit is rotating

at a relatively high speed, tak-

ing very smalr bites, producing

tiny, clean cut chips..

Forcing the feed of the cutting

bit forward too fast slows the

RPM of the cutting bit, and the

bit takes bigger bites as it ro-

tates,. Bigger bites mean bigger

chips and a rough finish. This

forcing action can also cause

the router motor to overheat.

Fig. 18

Bit

Shank

Fig. 18a

Cut

Bit

Shank

TOO

!

Under extreme force-feeding conditions, the RPMs cari become so slow and the

bites become so large that chips become partially cut _ff, causing splintering and

gouging of the work piece.

The router will make clean, smooth cuts if allowed to ruln freely without the over-

load of forced feeding. You can detect forced feeding !_ the sound of the motor..

Its usual high-pitched whine will sound lower and stronger as it loses speed.

Holding the router against the work piece will also be s!rained and harder to do

FEEDING TOO SLOW (Fig. 18a)

When you feed the cutting bit too slowly, the rotating c_

new wood fast enough to take a bite. Instead, it scrape

ticles. This scraping produces heat, which can glaze, b

work piece and, in extreme cases, overheat the cutting

When the cutting bit is scraping instead of cutting, the

control as you feed it.

itting bit does not cut into

;away sawdust-like par-

Jrn and mar the cut in the

bit_

outer is more difficult to

L

28190 ManuaLRevised_07-0409 i Page 30