Locking

Pin

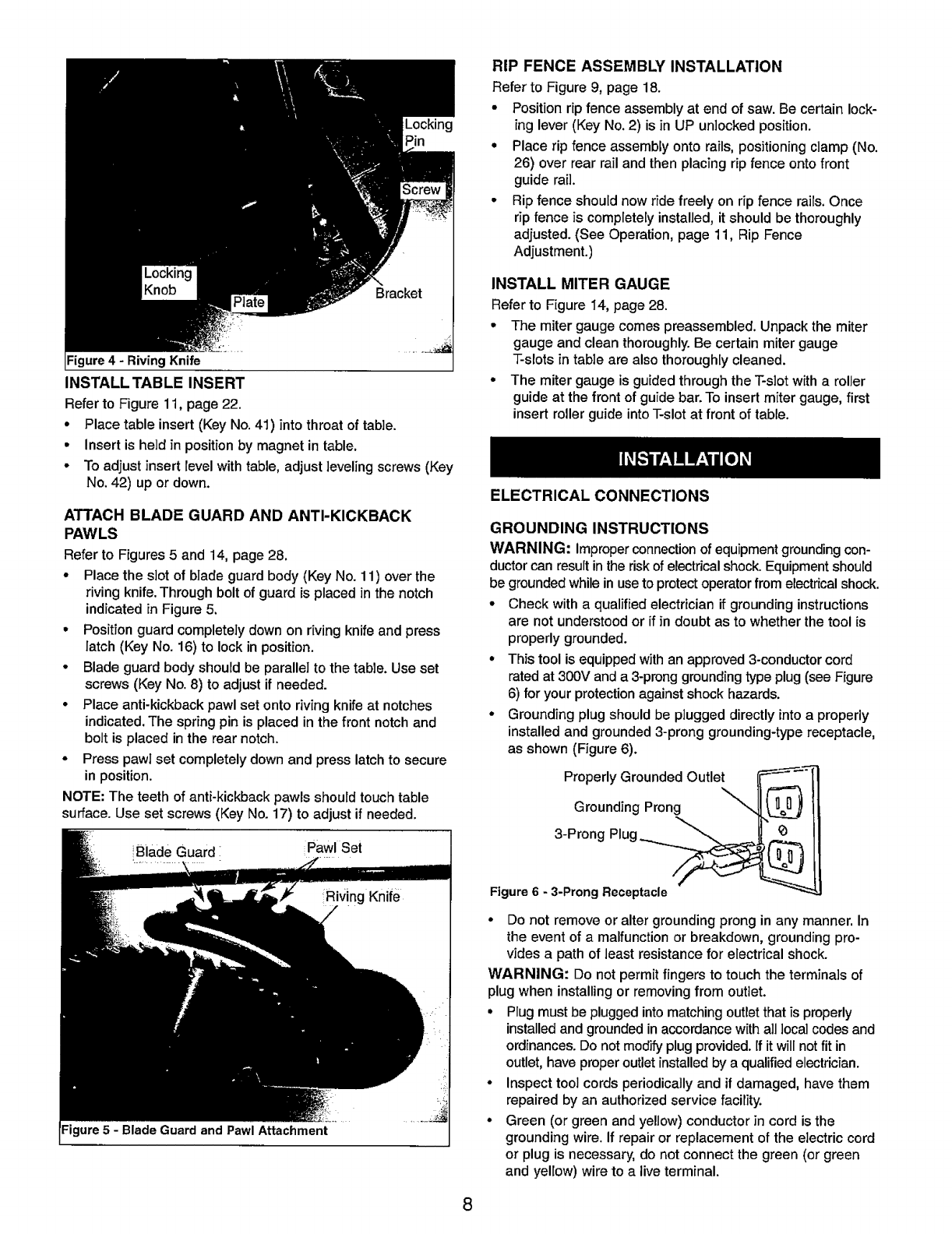

Figure 4 - Riving Knife

INSTALL TABLE INSERT

Referto Figure 11, page 22.

° Place table insert (Key No.41) into throat of table.

• Insert is held in position by magnet in table.

• Toadjust insert levelwith table, adjust leveling screws (Key

No. 42) up or down.

RIP FENCE ASSEMBLY INSTALLATION

Refer to Figure 9, page 18.

° Positionrip fence assembly at end of saw.Be certainlock-

ing lever(KeyNo.2) isin UP unlockedposition.

° Place rip fence assembly ontorails,positioningclamp(No.

26) overrear rail and thenplacingripfence ontofront

guide rail.

° Rip fence should now ride freely on rip fence rails. Once

rip fence is completely installed, it should be thoroughly

adjusted. (See Operation, page 11, Rip Fence

Adjustment.)

INSTALL MITER GAUGE

Referto Figure 14, page 28.

° The mitergauge comespreassembled.Unpackthe miter

gauge and cleanthoroughly.Be certainmitergauge

T-slotsin tableare alsothoroughlycleaned.

° The mitergaugeis guidedthroughthe T-slotwitha roller

guideat the frontofguidebar.To insertmiter gauge,first

insert rollerguideintoT-slotat front of table.

ATTACH BLADE GUARD AND ANTI-KICKBACK

PAWLS

Refer to Figures 5 and 14, page 28.

• Placethe slot of blade guardbody (Key No. 11) overthe

riving knife.Throughbolt of guardis placed in the notch

indicatedin Figure5.

• Positionguardcompletelydownon rivingknifeand press

latch (KeyNo. 16) tolockin position.

° Bladeguardbody should be parallel tothe table.Use set

screws(Key No.8) to adjustif needed.

• Placeanti-kickbackpawlset ontorivingknifeat notches

indicated.The springpin isplacedin the front notchand

bolt is placed inthe rearnotch.

° Press pawlset completelydown and presslatchto secure

in position.

NOTE:The teeth of anti-kickback pawls should touchtable

surface. Use set screws (Key No. 17) to adjust if needed.

iBlade Guard Pawl Set

ELECTRICAL CONNECTIONS

GROUNDING INSTRUCTIONS

WARNING: improperconnectionof equipmentgroundingcon-

ductorcan resultinthe riskofelectricalshock.Equipmentshould

be groundedwhileinusetoprotectoperatorfrom electricalshock.

• Check witha qualifiedelectrician ifgroundinginstructions

are not understoodor if in doubtas to whetherthe tool is

properlygrounded.

• Thistool isequippedwithan approved3-conductorcord

rated at 300V anda 3-pronggroundingtypeplug(see Figure

6) for yourprotectionagainst shock hazards.

• Grounding plug should be pluggeddirectlyintoa properly

installedand grounded3-prong grounding-typereceptacle,

as shown (Figure6).

Properly Grounded Outlet

Grounding Prong

3-Prong Plug ___

Figure 6 - 3-Prong Receptacle

° Do not remove or alter grounding prong in any manner. In

the event of a malfunction or breakdown, grounding pro-

vides a path of least resistance for electrical shock.

WARNING: Do not permit fingers to touch the terminals of

plug when installing or removing from outlet.

• Plug must be plugged into matching outlet that is properly

installed and grounded in accordance with all local codes and

ordinances. Do not modify plug provided. If it will not fit in

outlet, have proper outlet installed by a qualified electrician.

° Inspect tool cords periodically and if damaged, have them

repaired by an authorized service facility.

• Green (or green and yellow) conductor in cord is the

grounding wire. If repair or replacement of the electric cord

or plug is necessary, do not connect the green (or green

and yellow) wire to a live terminal.

8