Heat build-up in the tool can cause serious damage

to the tool. Allow transformer to cool down to room

temperature between each welding or each anneal-

ing operation. It is a safe procedure to let the trans-

former be idle for at least 3 minutes between

successive welding/annealing operations.

BLADE ANNEALING

• After the blade has been welded, the weld area will

be very hard and brittle. Before the blade can be

used, it must be annealed and the flash removed.

• The blade weld is annealed by heating the blade

just under the melting temperature and then slowly

cooling the weld.

NOTE: Reset weld pressure adjustment knob to "0"

prior to annealing. Failure to do so can cause damage

to transformer.

• Press the anneal button until the weld area glows

a cherry red and then release the anneal button.

CAUTION: The blade weld will melt, destroying the

weld, if the anneal button is not released as soon as

the weld glows cherry red.

• Let the blade cool for several seconds.

• Press the anneal button again, but release the but-

ton before the weld glows as brightly as the first

time.

• Wait several seconds until the blade cools further.

• Repeat the anneal process 6 or 7 times, decreasing

the anneal temperature each time.

• The weld flash must be ground from the blade. See

"Grinding Blade".

GRINDING BLADE

• After annealing the blade, the metal buildup or flash

must be ground from the blade.

• Toggle grinder switch to the ON position.

• Flip the grinder guard open, exposing the top of the

grinding wheel.

• Weld should be ground to same thickness as blade.

• Grind flash off underside of blade taking care not

to grind into blade.

• Turn blade inside out and grind other side of blade

same as first side (or, flip the grinder guard to the

closed position and use the bottom of the wheel).

• Take care not to grind into blade.

• Turn blade inside out again (to original shape).

• Turn grinder off when grinding is completed. The

blade must be annealed again.

ANNEAL BLADE AFTER GRINDING

• After flash has been removed, anneal the blade a

second time. The weld may have been hardened

by heat created during grinding. Repeat "Blade

Annealing" step.

• After second blade annealing operation, the blade

is ready for installation onto band saw. Follow band

saw instruction when installing and adjusting blade.

WARNING: Make certain that unit is disconnected

from power source before attempting to service or

remove any component.

CLEANING

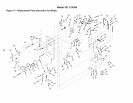

Refer to Figure 15.

• Keep machine and workshop clean. Do not allow

sawdust to accumulate on band saw.

• Keep wheels clean. Debris on wheels will cause

poor tracking and blade slippage.

• Keep mechanisms and threaded or sliding surfaces

clean and free of foreign particles.

• Operate band saw with a dust collector to minimize

clean up.

• Make sure that brush (Key No. 63) is in contact with

blade to properly remove foreign particles from

drive wheel.

LUBRICATION

Refer to Figures 15-17.

• The shielded ball bearings are permanently lubricat-

ed and require no further lubrication.

• Grease guide post (Figure 16, Key No. 36) once a

week. Grease speed operator shaft in gearbox hous-

ing (Figure 15, Key No. 28 and 45) and blade tension

lead screw (Figure 15, Key No. 16) every 100 hours.

Use grease gun on grease fitting every 100 hours

(Figure 17, Key No. 10). Grease table support

brackets every three months.

• Add light machine oil or air tool oil to air pump

(Figure 17, Key No. 49) when pump loses power

or fails to pump air.

• Occasionally apply a coat of paste wax to table

top to keep it slick and corrosion free.

KEEP BAND SAW IN REPAIR

• If power cord is worn or cut in any way, have it

replaced.

• Replace V-belt and blade when they are worn.

Replace any damaged or missing part.

• Use parts list to order parts.

CLEAN WELDER JAWS

After each welding operation, wipe welder jaws clean

of any oil, dirt or rust and scrape any flash deposited

on welder jaws.

Welder jaws must be kept clean at all times. The jaws

must be wiped clean of any dirt or oil and scraped

clean of flash after each weld.

The shear blades should be wiped with an oily cloth

to remove any dirt or rust.

To replace grinding wheel, remove two screws holding

grinder guard and remove guard. Hold grinding wheel

stationary and remove nut and washer. Install new wheel

on grinder motor shaft and fasten with washer and nut.

Make sure nut is tight. Attach grinder guard with two screws.

11