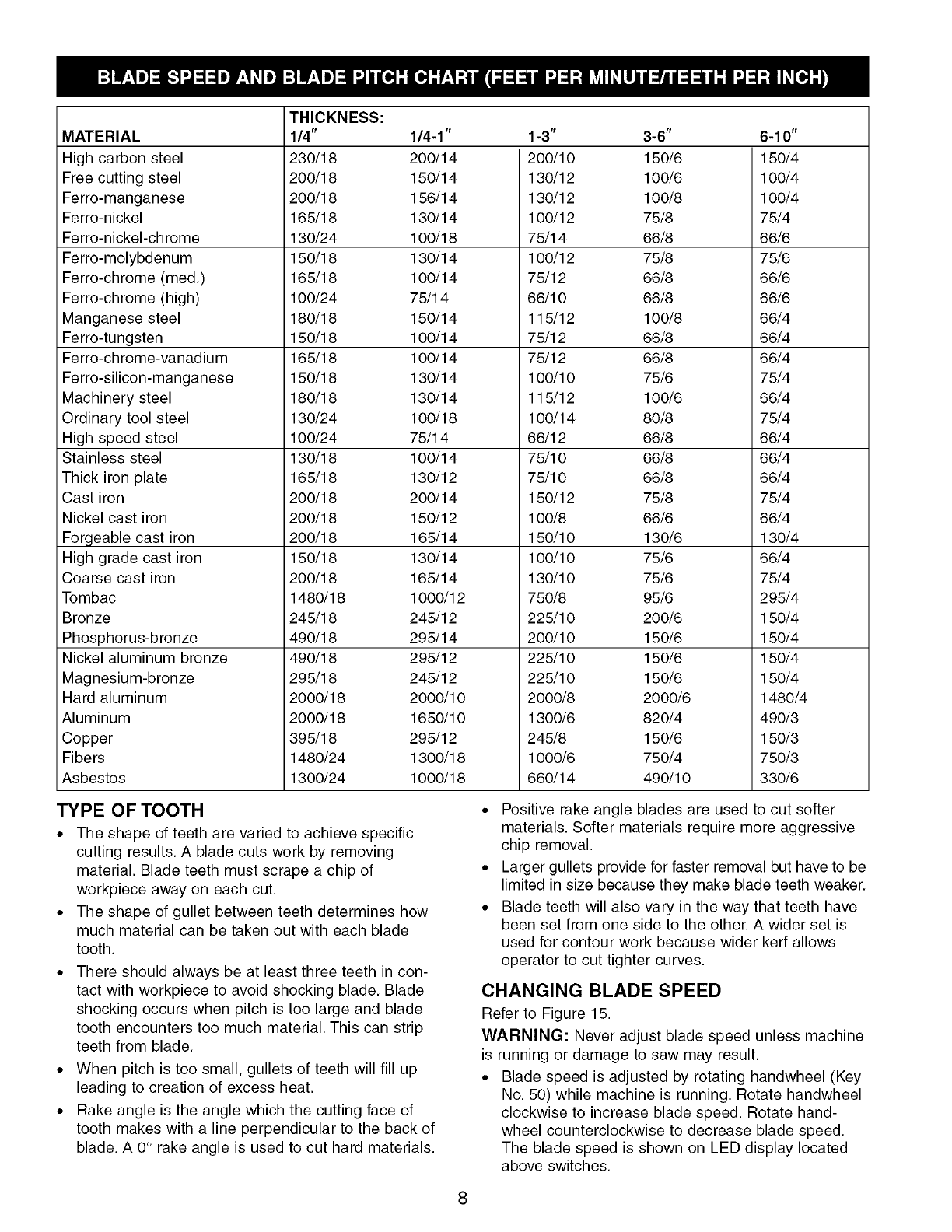

MATERIAL

Highcarbonsteel

Freecuttingsteel

Ferro-manganese

Ferro-nickel

Ferro-nickel-chrome

Ferro-molybdenum

Ferro-chrome(med.)

Ferro-chrome(high)

Manganesesteel

Ferro-tungsten

Ferro-chrome-vanadium

Ferro-silicon-manganese

Machinerysteel

Ordinarytoolsteel

Highspeedsteel

Stainlesssteel

Thickironplate

Castiron

Nickelcastiron

Forgeablecastiron

Highgradecastiron

Coarsecastiron

Tombac

Bronze

Phosphorus-bronze

Nickelaluminumbronze

THICKNESS:

1/4"

230/18

200/18

200/18

165/18

130/24

150/18

165/18

100/24

180/18

150/18

165/18

150/18

180/18

130/24

100/24

130/18

165/18

200/18

200/18

200/18

150/18

200/18

1480/18

245/18

490/18

490/18

1/4-1"

200/14

150/14

156/14

130/14

100/18

130/14

100/14

75/14

150/14

100/14

100/14

130/14

130/14

100/18

75/14

100/14

130/12

200/14

150/12

165/14

130/14

165/14

1000/12

245/12

295/14

295/12

.3 tt

200/10

130/12

130/12

100/12

75/14

100/12

75/12

66/10

115/12

75/12

75/12

100/10

115/12

100/14

66/12

75/10

75/10

150/12

100/8

150/10

100/10

130/10

750/8

225/10

200/10

225/10

.6 tr

150/6

100/6

100/8

75/8

66/8

75/8

66/8

66/8

100/8

66/8

66/8

75/6

100/6

80/8

66/8

66/8

66/8

75/8

66/6

130/6

75/6

75/6

95/6

200/6

150/6

150/6

Magnesium-bronze

Hard aluminum

Aluminum

Copper

Fibers

Asbestos

295/18

2000/18

2000/18

395/18

1480/24

1300/24

245/12

2000/10

1650/10

295/12

1300/18

1000/18

225/10

2000/8

1300/6

245/8

1000/6

660/14

150/6

2000/6

820/4

150/6

750/4

490/10

6-1O"

150/4

100/4

100/4

75/4

66/6

75/6

66/6

66/6

66/4

66/4

66/4

75/4

66/4

75/4

66/4

66/4

66/4

75/4

66/4

130/4

66/4

75/4

295/4

150/4

150/4

150/4

150/4

1480/4

490/3

150/3

750/3

330/6

TYPE OF TOOTH

• The shape of teeth are varied to achieve specific

cutting results. A blade cuts work by removing

material. Blade teeth must scrape a chip of

workpiece away on each cut.

• The shape of gullet between teeth determines how

much material can be taken out with each blade

tooth.

• There should always be at least three teeth in con-

tact with workpiece to avoid shocking blade. Blade

shocking occurs when pitch is too large and blade

tooth encounters too much material. This can strip

teeth from blade.

• When pitch is too small, gullets of teeth will fill up

leading to creation of excess heat.

• Rake angle is the angle which the cutting face of

tooth makes with a line perpendicular to the back of

blade. A 0° rake angle is used to cut hard materials.

• Positive rake angle blades are used to cut softer

materials. Softer materials require more aggressive

chip removal.

• Larger gullets provide for faster removal but have to be

limited in size because they make blade teeth weaker.

• Blade teeth will also vary in the way that teeth have

been set from one side to the other. A wider set is

used for contour work because wider kerf allows

operator to cut tighter curves.

CHANGING BLADE SPEED

Refer to Figure 15.

WARNING: Never adjust blade speed unless machine

is running or damage to saw may result.

• Blade speed is adjusted by rotating handwheel (Key

No. 50) while machine is running. Rotate handwheel

clockwise to increase blade speed. Rotate hand-

wheel counterclockwise to decrease blade speed.

The blade speed is shown on LED display located

above switches.

8