• Avoid accidental start-up. Make sure that the tool is

in the "off" position before plugging in.

• Do not force tool. It will work most efficiently at the

rate for which it was designed.

• Keep hands away from moving parts and cutting

surfaces.

• Never leave tool running unattended. Turn the

power off and do not leave tool until it comes to

a complete stop.

• Do not overreach. Keep proper footing and balance.

• Never stand on tool. Serious injury could occur if tool

is tipped or if blade is unintentionally contacted.

• Know your tool. Learn the tool's operation, applica-

tion and specific limitations.

• Use recommended accessories (refer to page 17).

Use of improper accessories may cause risk of

injury to persons.

• Handle workpiece correctly. Protect hands from

possible injury.

• Turn machine off if it jams. Blade jams when it digs

too deeply into workpiece. (Motor force keeps it

stuck in the work.) Do not remove summed or cut

off pieces until the saw is turned off, unplugged

and the blade has stopped.

WARNING: The operation of any power tool can result

in foreign objects being thrown into the eyes, which can

result in severe eye damage. Always wear safety goggles

complying with United States ANSI Z87.1 (shown on

package) before commencing power tool operation.

Safety goggles are available through your Sears catalog.

WARNING: Be careful not to touch overhead power

lines, piping, lighting, etc., if lifting equipment is used.

Band saw weighs approximately 1000 Ibs. Proper tools,

equipment and qualified personnel should be employed

in all phases of unpacking and installation.

IMPORTANT: Table is coated with a protectant. To

ensure proper fit and operation, remove coating.

Coating is easily removed with mild solvents, such as

mineral spirits, and a soft cloth. Avoid getting solution

on paint or any of the rubber or plastic parts. Solvents

may deteriorate these finishes. Use soap and water

on paint, plastic or rubber components. After cleaning,

cover all exposed surfaces with a light coating of oil.

Paste wax is recommended for table top.

WARNING: Never use highly volatile solvents. Non

flammable solvents are recommended to avoid possible

fire hazard.

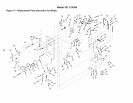

Refer to Figure 16.

CAUTION: Do not attempt assembly if parts are miss-

ing. Use operator's manual to order replacement parts.

MOUNT RIP FENCE

Refer to Figure 16.

Thread rip fence lock knob into rip fence (Key Nos. 43

and 42) and slide rip fence into groove on top of work

table. Secure rip fence with lock knob.

Refer to Figures 2-5, 14 and 17.

Check for shipping damage. If damage has occurred,

a claim must be filed with carrier. Check for complete-

ness. Immediately report missing parts to dealer.

The band saw comes assembled as one unit. Additional

parts which need to be fastened to the saw should be

located and accounted for before assembling:

A Rip Fence

B Knob

B

Figure 1 - Unpacking

Unbolt saw from shipping pallet and remove saw from

crate using eye bolt on saw and heavy duty lifting

equipment such as an overhead crane.

MOTOR

The 115/230 Volt AC motor has the following

specifications:

Horsepower (Continuous Duty) ................. 11/2

Voltage ............................... 115/230

Amps .................................... 18/9

Hertz ..................................... 60

Phase .................................. Single

RPM .................................... 1720

Before band saw is installed, a suitable location should

be chosen. Band saw weighs approximately 1000 Ibs.

1. Band saw needs to be set on a flat, level surface.

2. Make sure there is ample room for moving the work-

piece through the entire cut. There must be enough

room that neither the operator nor bystanders will

have to stand in line while using the tool.

3. Good lighting and correct power supply are also

required for a proper work area.

Mount saw on level surface using mounting brackets

welded to cabinet. Bolt cabinet to floor (hardware not

included).