TENSIONING BLADE

Refer to Figure 15.

• Tension blade by rotating handwheel (Key No. 38). Be

sure blade guides do not interfere with blade path.

• Tighten blade until it is properly tensioned.

• A properly tensioned blade will ring slightly when back

of blade is plucked (like a string on an instrument).

NOTE: Check tension of new blade. Additional tension

may be required after a few minutes of operation.

TRACKING BLADE

Refer to Figure 15.

• Track blade after it has been tensioned. A change

in blade tension will affect wheel alignment. Proper

tracking is achieved when upper and lower wheels

are aligned.

• Set screws (Key No. 23) are used to align the track-

ing bracket to the saw frame.

• Turn idler wheel (Key No. 5) by hand and observe

how blade rides on the wheels.

• If blade rides away from the cabinet, tilt wheel up by

turning knob (Key No. 30) clockwise.

• If blade rides into cabinet, tilt wheel down by turning

knob counterclockwise.

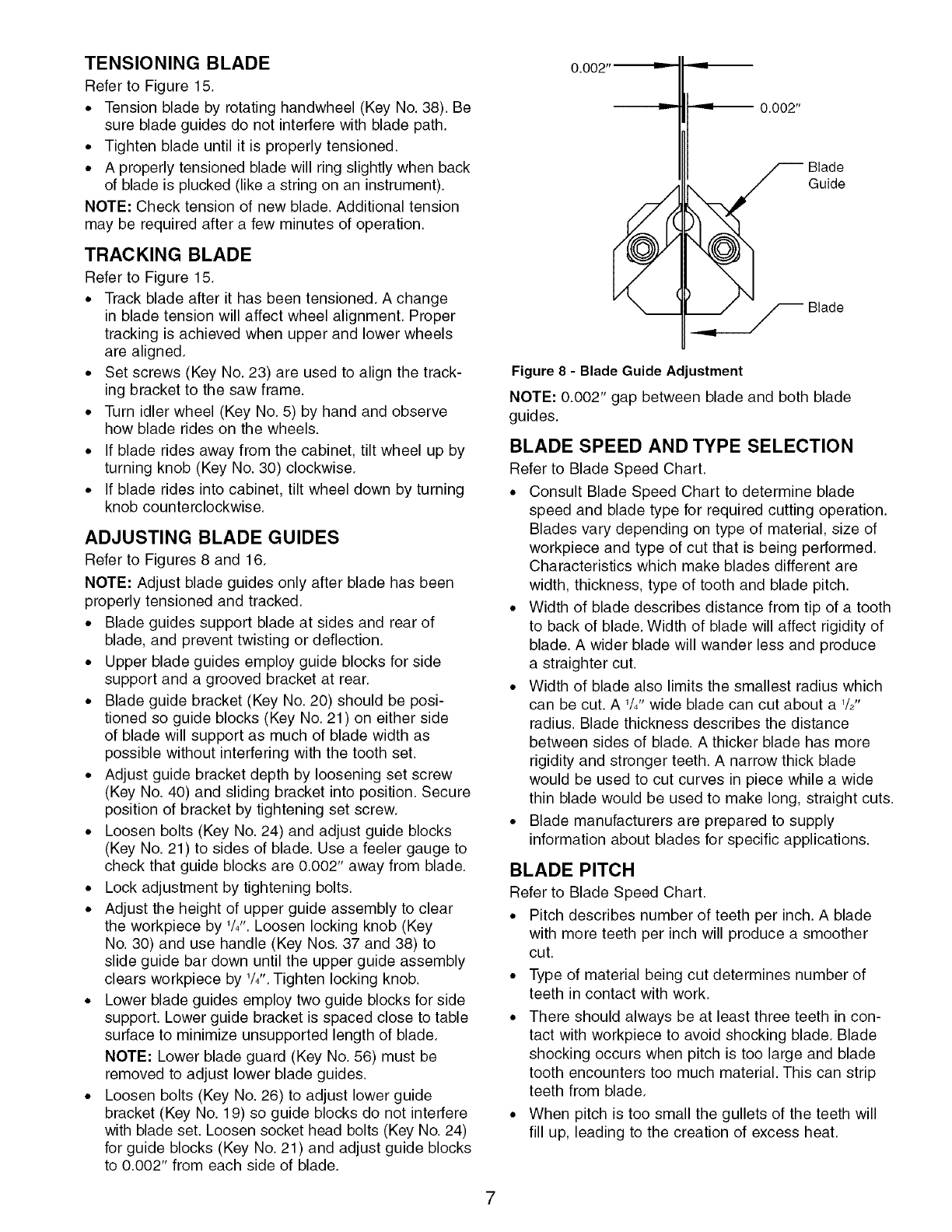

ADJUSTING BLADE GUIDES

Refer to Figures 8 and 16.

NOTE: Adjust blade guides only after blade has been

properly tensioned and tracked.

• Blade guides support blade at sides and rear of

blade, and prevent twisting or deflection.

• Upper blade guides employ guide blocks for side

support and a grooved bracket at rear.

• Blade guide bracket (Key No. 20) should be posi-

tioned so guide blocks (Key No. 21) on either side

of blade will support as much of blade width as

possible without interfering with the tooth set.

• Adjust guide bracket depth by loosening set screw

(Key No. 40) and sliding bracket into position. Secure

position of bracket by tightening set screw.

• Loosen bolts (Key No. 24) and adjust guide blocks

(Key No. 21 ) to sides of blade. Use a feeler gauge to

check that guide blocks are 0.002" away from blade.

• Lock adjustment by tightening bolts.

• Adjust the height of upper guide assembly to clear

the workpiece by 1/4".Loosen locking knob (Key

No. 30) and use handle (Key Nos. 37 and 38) to

slide guide bar down until the upper guide assembly

clears workpiece by 1/4".Tighten locking knob.

• Lower blade guides employ two guide blocks for side

support. Lower guide bracket is spaced close to table

surface to minimize unsupported length of blade.

NOTE: Lower blade guard (Key No. 56) must be

removed to adjust lower blade guides.

• Loosen bolts (Key No. 26) to adjust lower guide

bracket (Key No. 19) so guide blocks do not interfere

with blade set. Loosen socket head bolts (Key No. 24)

for guide blocks (Key No. 21) and adjust guide blocks

to 0.002" from each side of blade.

0.002"

0.002"

Blade

Guide

Blade

Figure 8 - Blade Guide Adjustment

NOTE: 0.002" gap between blade and both blade

guides.

BLADE SPEED AND TYPE SELECTION

Refer to Blade Speed Chart.

• Consult Blade Speed Chart to determine blade

speed and blade type for required cutting operation.

Blades vary depending on type of material, size of

workpiece and type of cut that is being performed.

Characteristics which make blades different are

width, thickness, type of tooth and blade pitch.

• Width of blade describes distance from tip of a tooth

to back of blade. Width of blade will affect rigidity of

blade. A wider blade will wander less and produce

a straighter cut.

• Width of blade also limits the smallest radius which

can be cut. A 1/Z'wide blade can cut about a 1/2"

radius. Blade thickness describes the distance

between sides of blade. A thicker blade has more

rigidity and stronger teeth. A narrow thick blade

would be used to cut curves in piece while a wide

thin blade would be used to make long, straight cuts.

• Blade manufacturers are prepared to supply

information about blades for specific applications.

BLADE PITCH

Refer to Blade Speed Chart.

• Pitch describes number of teeth per inch. A blade

with more teeth per inch will produce a smoother

cut.

• Type of material being cut determines number of

teeth in contact with work.

• There should always be at least three teeth in con-

tact with workpiece to avoid shocking blade. Blade

shocking occurs when pitch is too large and blade

tooth encounters too much material. This can strip

teeth from blade.

• When pitch is too small the gullets of the teeth will

fill up, leading to the creation of excess heat.