SPECIFICATIONS

Depth of throat ............................. 18"

Maximum depth of cut ...................... 10s/4''

Table size ........................... 23% x 21%"

Table tilt ............................ -15 to +15 °

Wheel diameter ............................ 18"

Blade length .............................. 140"

Blade width ............................. 1/8to %"

Blade speeds .... infinitely variable from 80 to 385 FPM

Overall dimensions .................. 75 x 37 x 30"

Shipping weight ........................ 1012 Ibs

Dust collection port ........................... 4"

CAUTION: Always observe the following safety

precautions:

• Make sure that blade guides and thrust bearings are

positioned and adjusted correctly to prevent side-

ways and rearward movement of the blade. Adjust

upper guide to just clear workpiece.

• Check to make sure blade is tensioned and tracking

properly. Do not over tension the blade in order to

prevent premature blade wear and breakage. Avoid

under tensioning to eliminate back and forth, side to

side blade movement as it cuts.

• Use proper blade and speed for the cutting operation.

• After turning saw on, allow blade to come to full

speed before attempting any cutting operation.

• Support workpiece properly and use a smooth

steady feed to guide work through the cut. Use

push sticks or push blocks when required.

• Keep hands away and out of line with moving parts.

• Always wear eye protection.

OPERATING SAW CONTROLS

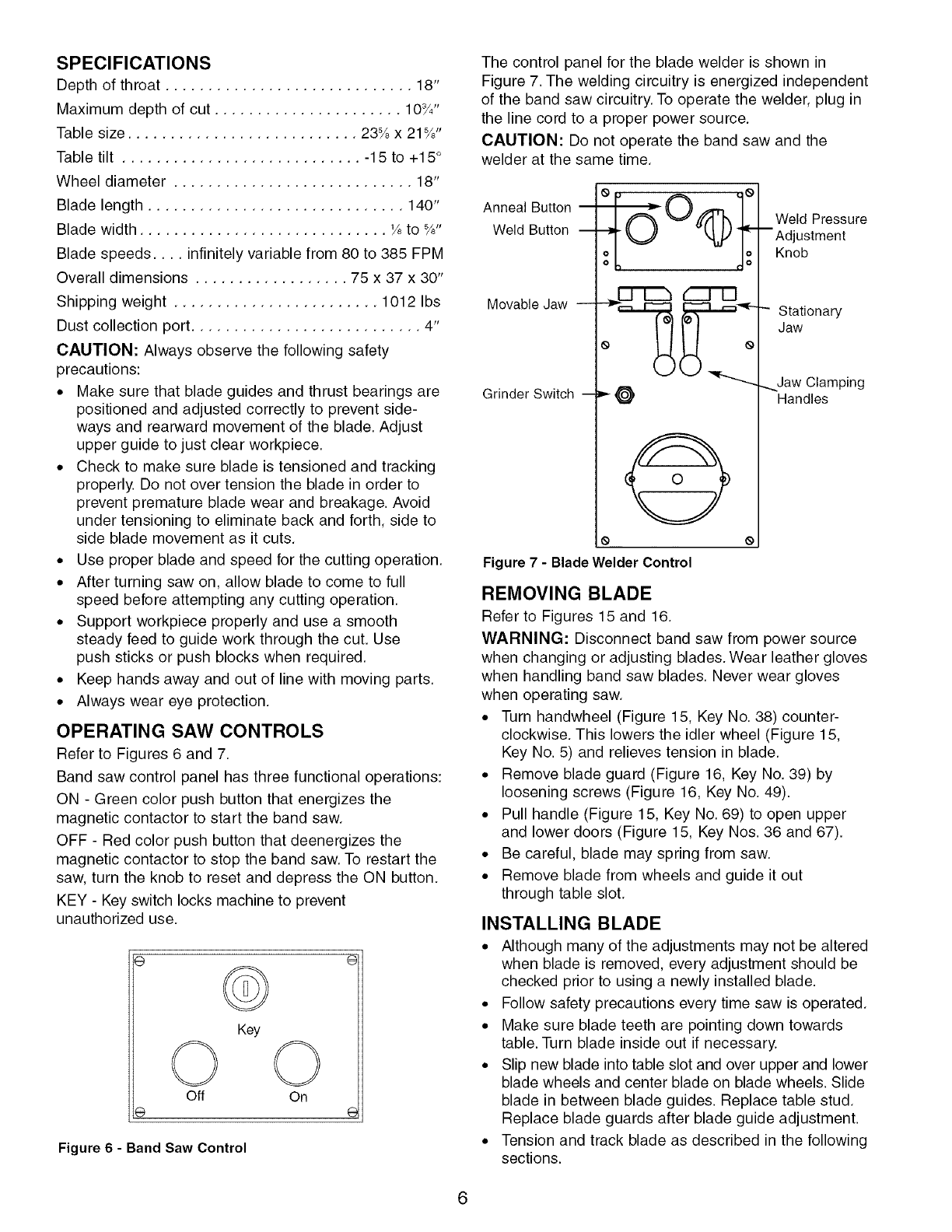

Refer to Figures 6 and 7.

Band saw control panel has three functional operations:

ON - Green color push button that energizes the

magnetic contactor to start the band saw.

OFF - Red color push button that deenergizes the

magnetic contactor to stop the band saw. To restart the

saw, turn the knob to reset and depress the ON button.

KEY - Key switch locks machine to prevent

unauthorized use.

Key

Off On

÷

Figure 6 - Band Saw Control

The control panel for the blade welder is shown in

Figure 7. The welding circuitry is energized independent

of the band saw circuitry. To operate the welder, plug in

the line cord to a proper power source.

CAUTION: Do not operate the band saw and the

welder at the same time.

Anneal Button

Weld Button --

Movable Jaw --

Grinder Switch -

cTD,

@

Figure 7 - Blade Welder Control

@

Weld Pressure

-- Adjustment

Knob

Stationary

Jaw

....Jaw Clamping

Handles

REMOVING BLADE

Refer to Figures 15 and 16.

WARNING: Disconnect band saw from power source

when changing or adjusting blades. Wear leather gloves

when handling band saw blades. Never wear gloves

when operating saw.

• Turn handwheel (Figure 15, Key No. 38) counter-

clockwise. This lowers the idler wheel (Figure 15,

Key No. 5) and relieves tension in blade.

• Remove blade guard (Figure 16, Key No. 39) by

loosening screws (Figure 16, Key No. 49).

• Pull handle (Figure 15, Key No. 69) to open upper

and lower doors (Figure 15, Key Nos. 36 and 67).

• Be careful, blade may spring from saw.

• Remove blade from wheels and guide it out

through table slot.

INSTALLING BLADE

• Although many of the adjustments may not be altered

when blade is removed, every adjustment should be

checked prior to using a newly installed blade.

• Follow safety precautions every time saw is operated.

• Make sure blade teeth are pointing down towards

table. Turn blade inside out if necessary.

• Slip new blade into table slot and over upper and lower

blade wheels and center blade on blade wheels. Slide

blade in between blade guides. Replace table stud.

Replace blade guards after blade guide adjustment.

• Tension and track blade as described in the following

sections.

6