15

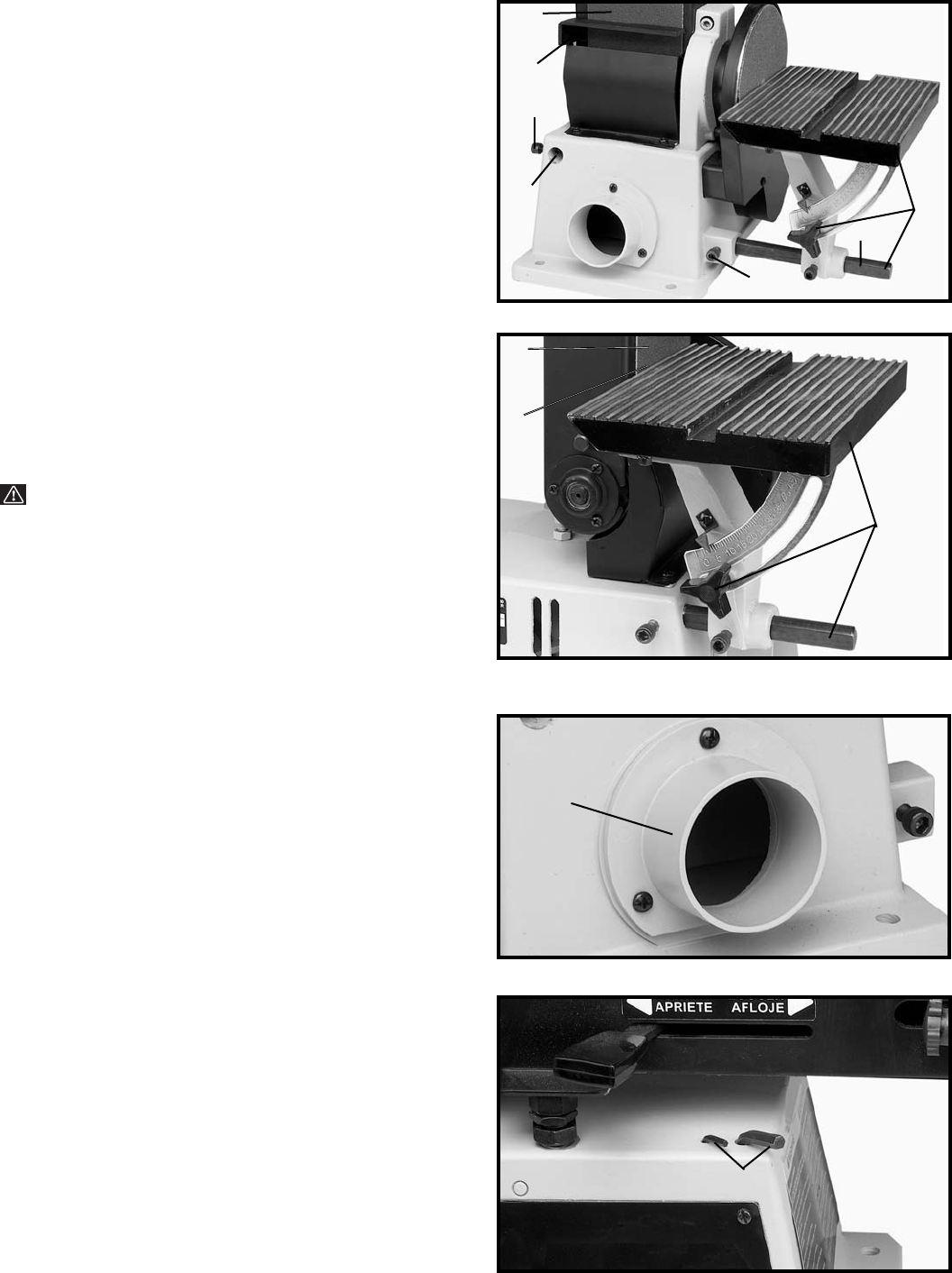

Fig. 39

Fig. 38

Fig. 37

Fig. 36

USING TABLE ASSEMBLY

WITH SANDING BELT

When the sanding arm (A) Fig. 36, is used in the vertical

position, the complete table assembly (B) can be moved

from the disc unit to the belt unit as follows:

1. DISCONNECT MACHINE FROM POWER SOURCE.

2. Remove the backstop (C) Fig. 36.

3. Thread the M8x1.25x20mm hex socket head screw

(D) Fig. 36, into base casting as shown. NOTE: Only

thread screw (D) partway into base casting.

4. Loosen screw (E) Fig. 36, and remove table

assembly (B) from disc unit. Insert bar (F) into hole (G) on

belt unit and tighten screw (D).

5. Fig. 37, illustrates the table assembly (B) assembled

to the belt unit.

WARNING: THE TABLE EDGE (G) MUST BE

POSITIONED A MAXIMUM OF 1/16 INCH AWAY

FROM THE SANDING BELT (H) TO AVOID TRAPPING

THE WORK OR FINGERS BETWEEN THE TABLE AND

SANDING BELT.

DUST CHUTE

A dust chute (A) Fig. 38, is supplied with your sander and

can be connected to a standard shop vacuum hose. The

outside diameter of the opening of the dust spout is 2-

1/2 inches.

WRENCH STORAGE

Two holes are provided in the base casting and are used

for storing the two wrenches (A) Fig. 39, supplied with

the sander.

A

C

D

G

E

F

B

H

G

B

A

A