13

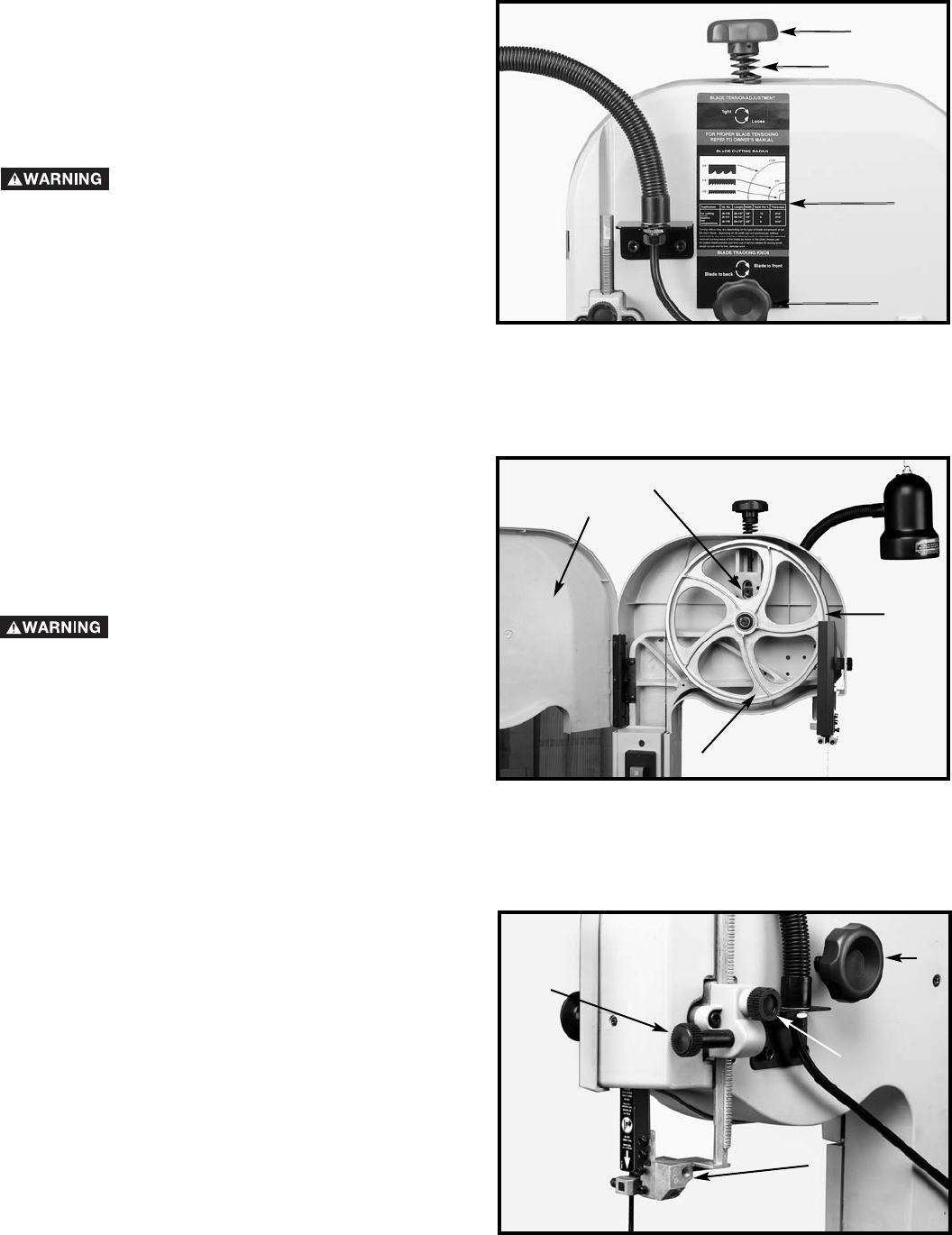

Fig. 24

ADJUSTING BLADE TENSION

Blades of 1/8", 1/4", and 3/8" in width by 59-1/2" in

length are available for use with your band saw. NOTE:

The blade tension must be adjusted to accommodate

different blade widths in order to provide proper blade

tracking, cutting performance, and blade life.

DISCONNECT MACHINE FROM POWER

SOURCE.

1. To install the desired blade, loosen screw (E) Fig. 25

with 5mm hex wrench provided and turn the tension knob

(A) Fig. 24, clockwise until the spring (B) begins to

compress.

2. Turn the tension knob (A) Fig. 24 an additional 2-1/2

turns for 1/8" wide blades; 3 turns for 1/4" wide blades;

and 4 turns for 3/8" wide blades. Tighten the screw (E)

Fig. 25.

3. A chart (C) Fig. 24 is located at the rear of the band

saw. This chart shows blade size, and the minimum

radius that can be cut with each size blade.

Fig. 25

TRACKING THE BLADE

DISCONNECT MACHINE FROM POWER

SOURCE.

1. Before tracking the blade, make sure that the blade

guides and blade support bearings are clear of the blade

so as not to interfere with the tracking adjustment. Also

make sure that the blade is tensioned properly. (Refer to

section “ADJUSTING BLADE TENSION”).

2. Open the hinged door (C) Fig. 25.

3. Rotate upper wheel (A) Fig. 25, clockwise by hand

and check to see if the blade (B) rides true on the

approximate center of the two wheels.

4. If an adjustment is necessary, turn the blade

tracking knob (D) Fig. 24 and/or Fig. 26, clockwise to

move the blade to the rear, and counterclockwise to

move the blade to the front. NOTE: Turn the blade

tracking knob (D) in small intervals to adjust the blade

tracking.

Fig. 26

ADJUSTING UPPER BLADE

GUIDE ASSEMBLY

The upper blade guide assembly (A) Fig. 26 should

always be no more than 1/8" above or as close as

possible to the top surface of the workpiece being cut.

Loosen knob (B), rotate knob (C) and position the guide

assembly (A) to the desired position. Then tighten the

knob (B).

A

B

A

B

C

D

C

B

A

C

E

D