15

ADJUSTING LOWER BLADE

GUIDES AND BLADE SUPPORT

BEARING

The lower blade guides and blade support bearing

should be adjusted at the same time as the upper guides

and support bearings as follows:

DISCONNECT MACHINE FROM POWER

SOURCE.

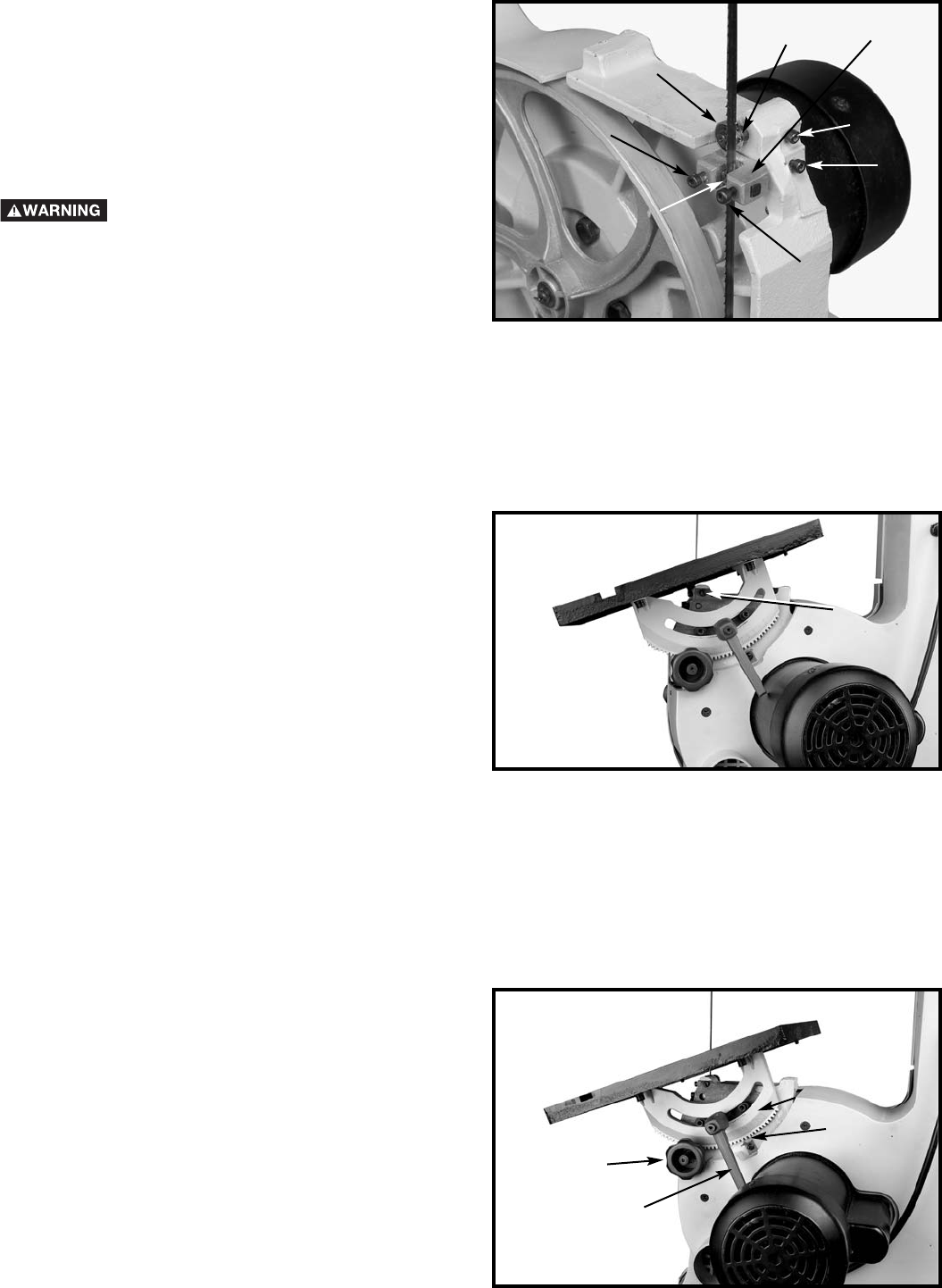

1. Loosen two screws (A) Fig. 29, and move guides (B)

as close as possible to the sides of the blade. Be careful

not to pinch the blade. Tighten the two screws (A).

NOTE: In Fig. 29, the table has been removed for clarity.

2. The front edge of the blade guides (B) Fig. 29 should

be adjusted so they are just behind the “gullets” of the

blade teeth. Loosen screw (C), and move the assembly

(D) in or out as necessary. Tighten screw (C).

3. The lower blade support thrust bearing (E) Fig. 29

prevents the saw blade from being pushed back too far

during cutting. The support bearing should be adjusted

approximately 1/32" behind the blade. Loosen screw (F)

Fig. 29, and move the bearing shaft (G) in or out as

necessary. Tighten screw (F).

4. The lower blade support bearing (E) Fig. 29 should

also be adjusted so that the blade overlaps the outside

diameter of the ball bearing by approximately 1/8". The

blade support bearing (E) is set on an eccentric shaft.To

change the position of the bearing (E), loosen the screw

(F) Fig. 29 and rotate the shaft (G) Fig 30 until the blade

properly overlaps the support bearing. Tighten screw (F)

Fig. 29.

Fig. 29

Fig. 30

G

F

E

C

A

A

B

Fig. 31

TILTING THE TABLE

The table can be tilted 45 degrees to the right. To tilt the

table, loosen lock handle (A) Fig. 31 and turn knob (B)

clockwise until desired angle is established. Then

tighten lock handle (A). NOTE: The table lock handle (A)

can be repositioned by pulling out on the handle and

repositioning it on the nut located underneath the hub of

the handle. A scale (C) and pointer (D) are provided to

indicate the degree of tilt.

A

D

C

B

D

G