68

English

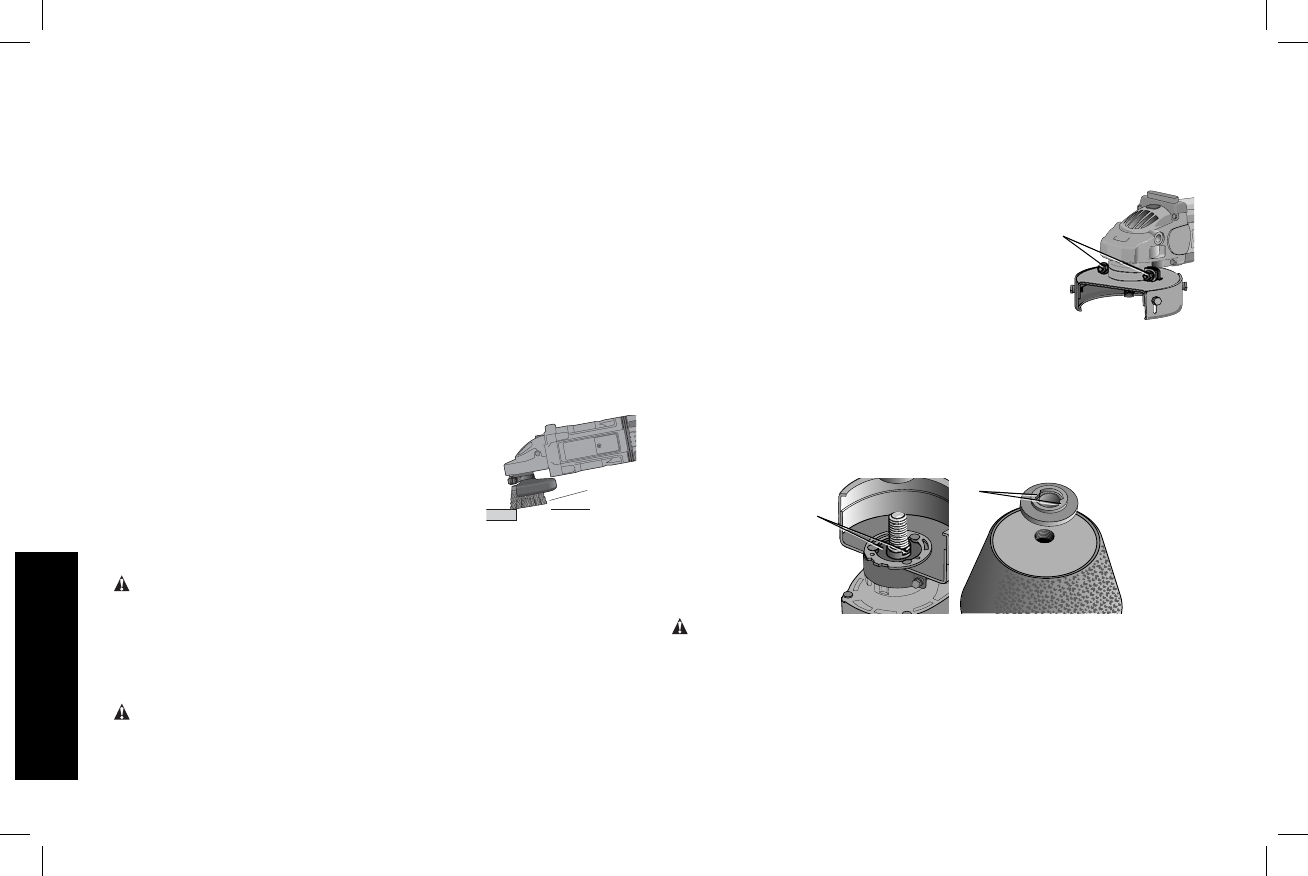

USING WIRE CUP BRUSHES AND WIRE WHEELS (FIG. 14)

Wire wheels and brushes can be used for removing rust, scale and

paint, and for smoothing irregular surfaces.

NOTE: The same precautions should be taken when wire brushing

paint as when sanding paint (refer to Precautions To Take When

Sanding Paint).

1. Allow the tool to reach full speed before touching the tool to the

work surface.

2. Apply minimum pressure to work surface, allowing the tool to

operate at high speed. Material removal rate is greatest when the

tool operates at high speed.

3. Maintain a 5° to 10° angle between the tool and work surface

for wire cup brushes.

4. Maintain contact between the edge of the wheel and the work

surface with wire wheels.

5. Continuously move the tool in a forward and

5˚–10˚

FIG. 14

back motion to avoid creating gouges in

the work surface. Allowing the tool to rest

on the work surface without moving, or

moving the tool in a circular motion causes

burning and swirling marks on the work

surface.

6. Remove the tool from the work surface before turning the tool off.

Allow the tool to stop rotating before setting it down.

CAUTION: Use extra care when working over an edge, as a

sudden sharp movement of grinder may be experienced.

Mounting and Using Flaring Cup

(Type 11) Wheel

MOUNTING FLARING CUP WHEEL GUARD (FIG. 15)

WARNING: The flaring cup wheel guard is not included with this

tool. Flaring cup wheels require proper flanges and guards.

4" (101 mm) flaring cup wheel guard D284934 and 5"–6"

(127–152 mm) flaring cup wheel guard D284936 are available as

accessories and include proper flange. Failure to use the proper

flange and guard can result in injury resulting from wheel break age

and wheel contact.

1. Install the guard as shown in Figure 15.

2. Guard body should be positioned between

S

FIG. 15

the spindle and the operator to provide

maximum operator protection.

3. Securely tighten the two clamping screws

(S) supplied with the guard.

MOUNTING FLARING CUP WHEEL

(FIG. 16)

1. Install the flaring cup wheel backing flange, aligning the flats on

spindle (T) with the flats on backing flange (O).

2. Thread the flaring cup wheel on spindle by hand, seating wheel

against backing flange.

3. Depress the spindle lock button and tighten the wheel by hand.

4. To remove the wheel, reverse the above procedure.

T

O

FIG. 16

CAUTION: Failure to properly seat the wheel against backing

flange before turning the tool on may result in damage to the tool or

the wheel.

NOTE: Adjust the guard skirt so that only 1/8" (3.17 mm) of the wheel

is exposed by loosening the bolts, allowing the guard to lengthen.

Tighten the guard skirt bolts securely before using the grinder.