10

© 2012 Emerson Climate Technologies, Inc.

Printed in the U.S.A.

AE4-1395

Application Engineering

BULLETIN

SERVICE PROCEDURES

Modulation Troubleshooting

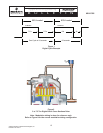

The modulation valve and solenoid coil are engineered

forspecicusewiththedigitalscroll.Don’tattemptto

substitute replacement solenoid coils that are not of

the correct part number. The 3 to 7.5 ton modulation

valves must be installed in the correct orientation and

with the arrow on the valve pointing to suction. Installing

a modulation valve in a horizontal position, or with the

suction and discharge connections reversed, can result

in sporadic operation of the modulation valve. See

Figure 8 for an illustration of the correct valve location

and orientation.

Figure 10isatroubleshootingowcharttohelpwith

simple modulation problems. For more information on

troubleshooting the Copeland

™

Digital Compressor

Controller please refer to AE8-1328. For more

information on troubleshooting the Emerson Commercial

Comfort Controller please refer to AE8-1393.

3 to 7.5 Ton Modulation Valve Replacement

Procedure

The 3 through 7.5 ton digital scroll compressors employ

a modulation valve that is mounted external to the

compressor in the modulation tubing. To replace the

modulation valve, follow these recommended steps:

1. Disconnect and lockout the power to the unit.

2. Recover the refrigerant charge from the compressor/

system.

3. Remove the screw holding the coil to the valve

using a Phillips screwdriver or appropriate size nut

driver.

4. Remove the coil from the valve.

5. Using manifold gauges, double check to make

sure the refrigerant charge is completely

recovered from the compressor before

proceeding.

6. Using tubing cutters, cut the modulation tubing

close to the valve body leaving the valve tubing

stubs in the suction “T” connection and the swaged

tubing from the compressor top cap.

7. Carefully unbraze and remove the tubing stubs from

the suction “T” and top cap tubing swage. Carefully

unbrazing and removing these stubs will allow the

tubing/suction“T”ttingtobereused.

8. Afterthesettingshavecooled,cleanthettings

and prepare to braze the new valve in place. Wrap

a wet rag around the valve body to keep from

overheating the valve.

9. Using standard brazing practices for refrigeration

systems, carefully braze the new valve into the

system, directingthe torchame awayfrom the

valve body.

10. Check for leaks using nitrogen with a properly sized

regulating and relief valve.

11. Install the solenoid coil and torque the retaining

screw to 25 in-lbs.

12. Evacuate the compressor/system and put the

system back into operation.

8 To 15 Ton Modulation Valve Replacement

Procedure

The 8 through 15 ton digital scroll compressors have

a modulation valve that is replaceable in the event the

valve stops functioning. The modulation valve threads

into a receptacle that is inside the small terminal box on

the compressor. To replace the modulation valve, follow

these recommended steps:

1. Disconnect and lockout the power to the unit.

2. Recover the refrigerant charge from the compressor/

system.

3. Remove the cover from the small terminal box and

remove the screw holding the coil to the valve using

a Phillips screwdriver or appropriate size nut driver.

4. Remove the coil from the valve and clean the area

around the valve body to prevent debris and dirt

from entering the system when changing the valve.

5. Using manifold gauges, double check to make

sure the refrigerant charge is completely

recovered from the compressor before

proceeding.

6. Using a 7/8” deep well socket and ratchet, turn the

valve counterclockwise to remove the valve.

7. Visually inspect the valve receptacle on the

compressor for damage or debris. Ensure that the

blacko-ringandwhiteTeongasketareremoved

with the valve and do not remain on the valve

receptacle.

8. The replacement valve should have a new,

black o-ringand white,Teongasket as shown: