7

© 2012 Emerson Climate Technologies, Inc.

Printed in the U.S.A.

AE4-1395

Application Engineering

BULLETIN

Modulation Control

Two different controls are available from Emerson to

provide digital scroll modulation control, the Copeland

Scroll

™

Digital Compressor Controller and the Emerson

Commercial Comfort Controller.

The Copeland Scroll

™

Digital Compressor Controller is

an open loop controller that provides control, protection,

and diagnostics for the digital scroll and is suited for

OEM applications. The system controller supplied by the

OEM calculates the required compressor capacity and

communicates that capacity to the digital scroll controller

via a 1-5 VDC analog signal. For more information on

the Copeland Scroll Digital Compressor Controller please

refer to AE8-1328.

The Emerson Commercial Comfort Controller is a closed

loop controller that provides modulation control based

on space temperature and is suited for both OEM and

retrotapplications.Thiscontrolleristypicallylocatedin

the conditioned space and controls the modulation cycle

of the compressor without the need for an additional

system controller. For more information on the Emerson

Commercial Comfort Controller, please refer to AE8-1393.

NOTICE

For OEMs that choose their own controls

package, the controls must include the protection

features incorporated into the Copeland Scroll

™

Digital Compressor Controller. Please consult

with Application Engineering for a list of these

requirements.

APPLICATION TESTS

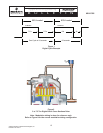

Oil Level Verication

If the system conguration is more complex than a

single circuit packaged system with one compressor,

evaporator, and condenser, an oil return test is highly

recommended during system development testing. For

this test a sample compressor with a sight-tube should

be used to observe the oil level over the entire operating

range of the system at the expected compressor

modulation rates, to ensure an adequate oil level in

the compressor at all times. The oil level should not

go below the weld points of the lower bearing bracket

for the 3 through 7.5 ton compressors. For the 8 ton

and larger digital scrolls the minimum oil level is 1.5"

(40 mm) below the center of the standard oil sight-

glass on the compressor. If the oil level falls below the

prescribed level for more than a few minutes either more

oil is required in the system or an oil recovery cycle is

needed. For more information on what an oil recovery

cycle is, please consult with Application Engineering.

If the system contains more than 20 pounds (9 kg) of

refrigerant,itisourrecommendationtoaddoneuid

ounce of additional oil for every 5 pounds (15 ml/kg)

of refrigerant over this amount. This is a starting point

and oil should be added as determined through system

testing or as required by the end use application in the

eld.

The compressor oil level should be checked with

the compressor "off" to avoid the sump turbulence

when the compressor is running. Manifolded

compressors should have their oil levels checked

after 20 to 30 seconds of off time, to allow oil

balancing between the manifolded compressors.

Excessive Liquid Flood Back Tests

It is expected that the design will not ood during

operation at all of the varying loaded and modulation

conditions. This places demanding requirements

on theow control deviceto control refrigerantow

and superheat all the way down to 10% of full load.

Throughout the operating range of the unit, the

suction superheat must remain positive. If the

ow control deviceis unable to maintain superheat,

an electronic expansion valve, accumulator, or other

means must be taken to maintain at least 20°F of

compressor sump superheat.

Operating Envelope Test

The operating envelopes and recommended modulation

ranges are shown in Figures 4 and 5. System testing must

be performed if operation outside of these recommended

ranges is desired. System testing should consist of unit/

system operation at abnormal operating conditions to

verify that suction superheat and compressor discharge

temperatures stay in a range that is healthy for the

compressor and tripping of the compressor overload is

avoided. Please consult with application engineering for

recommended tests and analysis of test data.

DIGITAL COMPRESSOR RETROFIT APPLICATIONS

Reasons To Retrot

Thereareanumberofreasonswhyretrottinganon-

modulatingsystemtoonethatmodulateswillbenet

the building owner and its occupants. Some of these

reasons include:

1. Reduced indoor temperature and humidity swings

2. Reduced power consumption and operating costs

3. Reduced cyclic losses

4. Qualicationforspecialutilityrebates

Applications that have excess cooling capacity and are

singlezone,constantorvariableair-owarecertainly

inthescopeofretrotopportunities.Unitsthatemploy