6

© 2012 Emerson Climate Technologies, Inc.

Printed in the U.S.A.

AE4-1395

Application Engineering

BULLETIN

bar) for R-407C & R-22 to prevent evaporator coil icing.

The cut in setting can be as high as 180 psig (12.5 bar)

for R-410A and 105 psig (7.2 bar) for R-407C & R-22 to

prevent rapid recycling in case of refrigerant loss.

For heat pumps, a cut out setting no lower than 20 psig

(1.4 bar) is recommended for R-410A and 10 psig (0.7

bar) for R-407C & R-22.

Scroll Temperature Protection

Most digital scrolls do not have internal discharge

gas temperature protection. In order for the Emerson

controllers to operate properly an NTC sensor must be

attached to the compressor discharge line as close as

possibletothecompressordischargetting.Forbest

response the sensor should be insulated. See Table 1

of AE8-1328 for thermistor temperature vs. resistance

values. Refer to Table 4 for part numbers of discharge

line thermistors. Figure 7 illustrates the two different

types of discharge thermistors.

The ZRD61 through ZRD81KC compressors have a

discharge thermistor that is inside of a well in the top

cap of the compressor. If this thermistor ever needs to

be replaced, it should be replaced with either 985-0199-

00 or 085-0204-00 as listed in Table 4.

Crankcase Heaters

A crankcase heater is required if the system charge

exceeds the system charge limits listed in Table 2.

For more information regarding regarding heater part

numbers and installation location please refer to the

equivalent non-digital scroll Application Engineering

bulletin listed on Page 4.

Oil Type and Oil Removal

Mineral oil is used in the ZRD*KC compressors for

R-22 applications. Polyolester (POE) oil is used in

the ZRD*KCE and ZPD*KCE compressors for R-22

& R-407C and R-410A applications respectively. See

the compressor nameplate for the original oil charge. A

completerechargeshouldbeapproximatelyfouruid

ounces (118 ml) less than the nameplate.

It is an approved practice to use ZRD*KCE compressors

with POE to replace ZRD*KC compressors with mineral

oil in R-22 service applications. R-22 has been approved

for use with both mineral and POE and some mixing of

these oil in the system is acceptable.

If additional oil is needed in the field for POE

applications, Copeland

™

Ultra 32-3MAF, Lubrizol

Emkarate RL32-3MAF, Parker Emkarate RL32-3MAF/

Virginia LE32-3MAF, or Nu Calgon 4314-66 (Emkarate

RL32-3MAF) should be used. Copeland Ultra 22 CC,

Hatcol EAL 22CC, and Mobil EAL Arctic 22 CC are

acceptable alternatives.

If additional oil is needed in theeld for mineral oil

applications, Sonneborn Suniso 3GS or Chevron

Texaco Capella WF32 should be used.

CAUTION

POE must be handled carefully and the proper

protective equipment (gloves, eye protection, etc.)

must be used when handling POE lubricant. POE

must not come into contact with any surface or

material that might be harmed by POE, including

without limitation, certain polymers (e.g. PVC/CPVC

and polycarbonate).

Power Factor

During the loaded state the digital scroll compressor

operates at full capacity and the power factor is the

same as a standard scroll. However, when the scrolls are

unloaded, the power factor is much lower. If power factor

is an important consideration, the correcting capacitors

should be calculated using the full capacity data to avoid

problems associated with over correction. See AE9-1249

for more information on power factor correction.

Tandem Applications

Tandem compressors follow the same application

guidelines as single compressors outlined in this bulletin.

The refrigerant charge limit for tandem compressors is

shown in Table 2. A tandem circuit with a charge over

this limit must have crankcase heaters applied to both

compressors.

Tandem compressor assemblies are available for

purchase from Emerson. In lieu of purchasing the

assembled tandem, the OEM has the option to

purchase the tandem-ready compressors to assemble

the compressors into a tandem conguration in their

manufacturing plant. Drawings of the tandem manifolds

are available by contacting your application engineer.

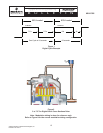

Figure 9 illustrates a typical tandem compressor

assembly using 3 through 7.5 ton scroll compressors.

Note that only one compressor in the tandem assembly

is a digital scroll compressor. Customers that choose

to design and build their own manifolds for tandem

and trio compressor assemblies are ultimately

responsible for the reliability of those manifold sets.

For more information on tandems, please refer to the

non-modulating compressor Application Engineering

bulletins listed on Page 4.