4

© 2012 Emerson Climate Technologies, Inc.

Printed in the U.S.A.

AE4-1395

Application Engineering

BULLETIN

Introduction

The 3 to 15 ton Copeland Scroll Digital

™

compressors

described in this bulletin include the follow compressor

model numbers:

R-410A R-22 & R-407C

ZPD34 to ZPD54K5 ZRD36 to ZRD81KC

ZPD61 to ZPD91KC ZRD94 to ZRD125KC

ZPD103 to ZPD182KC

ZPD and ZRD digital scroll compressors are variable

capacity compressors that can modulate down to 10%

of full load. Digital scrolls are suitable for a variety of

applications where a variable capacity compressor is

useful, such as VAV applications, dedicated outside

air units, units that typically used hot gas bypass for

capacity control, and applications that require accurate

control of temperature and humidity. Other applications

include multiple compressor systems where modulation

is required over the entire operating range of the system

and in applications where compressor starting and

stopping is unacceptable. Typical digital scroll model

numbers are ZRD94KCE-TF5 and ZPD182KCE-TWD.

This bulletin describes the operating and application

differences with respect to the equivalent fixed

capacity Copeland Scroll

™

compressors. The following

Application Engineering bulletins should be consulted

for non-modulating scroll application guidelines:

AE4-1331 1.5 to 5 Ton R-410A

AE4-1365 5 to 7.5 Ton R-410A

AE4-1303 8 to 15 Ton R-22, R-407C & R-410A

AE4-1312 1.5 to 7 Ton R-22 & R-407C

Nomenclature

The model number of the Copeland Scroll Digital

compressors includes the approximate nominal

60 Hz capacity at the AHRI high temperature full

load air conditioning rating point. An example is the

ZPD120KCE-TFD, which has approximately 120,000

Btu/hr cooling capacity at the air conditioning rating

point when operated on 60 Hz. Note that the same

compressor will have approximately 5/6 of this capacity

or 100,000 Btu/hr when operated on 50 Hz power.

Please refer to the Online Product Information at

www.EmersonClimate.com for more information on

performance at part load.

Digital Compressor Operation

The digital scroll is capable of seamlessly modulating

its capacity from 10% to 100%. A normally closed

(de-energized) solenoid valve is a key component for

achieving modulation. When the solenoid valve is in its

normally closed position, the compressor operates at

full capacity, or loaded state. When the solenoid valve

is energized, the two scroll elements move apart axially,

or into the unloaded state. During the unloaded state,

the compressor motor continues running, but since

the scrolls are separated, there is no compression.

During the loaded state, the compressor delivers 100%

capacity and during the unloaded state, the compressor

delivers 0% capacity. A cycle consists of one loaded

state and one unloaded state. By varying the time of

the loaded state and the unloaded state, an average

capacity is obtained. The lowest achievable capacity is

10% which equates to 1.5 seconds of pumping during

one 15 second cycle.

An example for the 15 second controller cycle: In any

15 second cycle, if the loaded time is 10 seconds and

the unloaded time is 5 seconds, the average capacity

is 66% or if the loaded time is 5 seconds and the

unloaded time is 10 seconds the capacity during that

15 second period is 33%. See Figure 1 for a graphical

representation of the digital cycle, and Figure 6 for

a graph showing solenoid on-time vs. compressor

capacity.

How it Works

The digital scroll compressor unloads by taking

advantage of the Copeland Scroll

compressor's

axial compliance. All Copeland Scroll compressors

are designed so that the compression elements can

separate axially a few thousands of an inch. The 3

through 7.5 ton compressors described in this bulletin

use a lift piston mechanism to separate the scrolls during

the unloaded state. When the solenoid is energized the

volume on top of the piston is vented to the low side

allowingthepistonandxedscrollassemblytomove

axial away from the orbiting scroll. When the solenoid is

de-energized the piston is forced down and the scrolls

are loaded axially.

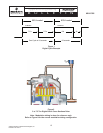

The 8 ton and larger digital scroll compressors employ

a solenoid valve that is mounted on the side of the

compressor that vents the intermediate cavity to the

low side of the compressor during the unloaded state.

During the loaded state the solenoid valve is de-

energized and the intermediate cavity is pressurized

toloadtheoatingsealandscrollsaxially.

Please refer to Figures 2 and 3 for cross sectional

pictures of the two digital modulation mechanisms.

APPLICATION CONSIDERATIONS

Operating Envelope

The operating envelope of the digital scroll compressors

for all loading conditions is shown in Figures 4 and 5.