9

© 2012 Emerson Climate Technologies, Inc.

Printed in the U.S.A.

AE4-1395

Application Engineering

BULLETIN

7. Using the appropriate lifting devices, carefully

remove the compressor from the system.

The following steps should be followed to install the digital

compressor into the system.

1. Before removing the rubber plugs, install the

compressor in the unit on the mounting grommets

using the appropriate lifting devices.

2. Install the compressor mounting bolts.

3. Connect the suction and discharge lines using

standard brazing practices.

4. If the compressor has an external modulation valve

and tubing (3 to 7.5 ton only) refer to Figure 8 for the

correct valve orientation and position. Wrap a wet

rag around the valve and complete the assembly

by brazing the valve and tubing into place.

5. Check for leaks using nitrogen with a properly sized

regulating and relief valve.

6. Connect conduits and wiring to the compressor.

Inspect and/or replace the contactor. If the

compressor is 1-phase, install the correct run

capacitor.

NOTICE

The above procedures for changing the

compressor are not comprehensive and additional

steps/procedures may be necessary.

Refrigerant Flow Control

In the system with a digital compressor, the refrigerant

owcontrolvalveisrequiredtocontrolowacrossawide

rangeofowratesandvaryingpressuredifferentials.

Most balanced port thermostatic expansion valves can

controlowdowntoabout40%oftheirratedcapacity.

Excessive hunting and loss of superheat control can

result when asking a thermostatic expansion valve to

operate outside of its design range. For this reason,

the expansion device needs to be evaluated to ensure

reliable operation over the expected operating range.

Limiting the minimum compressor modulation rate to

a value that the expansion valve can tolerate should

be considered. Electronic expansion valves should be

considered if modulation over the entire range of the

compressor’s modulation range is anticipated.

Evaporator Air Flow

For the highest level of energy savings, comfort, and

efciencythevariablecapacitysystemshouldbecapable

of varyingthe airow. Variable frequencydrives and

tapped blowers are two means of reducing air ow.

Reducing air ow in humid or maritime climates is

important to maintain coil temperatures low enough to

remove latent heat. In desert and arid climates, because

oflowornolatentloads,airowislesscritical.

Thecontrolsrequiredforvariableairowarenotprovided

by Emerson so the contractor may need to consult with

controlsexpertsinthiseld.

Condenser Air Flow

Modulatingthecondenserairowisnotcriticaltothe

success of the application. For the highest level of energy

savings,condenserairowwillbereducedbasedonthe

compressor modulation rate, condensing temperature,

ambient temperature, etc.

Modulation Control

Thepreferredmodulationcontrolforretrotapplications

is the Commercial Comfort Controller. This controller is a

closed loop controller that is installed in the conditioned

space. The controller measures the space temperature

and through an algorithm in the controller, controls the

modulation of the digital scroll. The controller can be

positioned up to 300 feet from the compressor/unit, is

congurableforrooftopunitorheatpump,andiswired

like a commercial room thermostat. For more information

on the Commercial Comfort Controller please refer to

AE8-1393.

ASSEMBLY LINE PROCEDURES

3 To 7.5 Ton Modulation Valve Brazing Procedure

The external modulation valve is purchased and shipped

separately from the 3 to 7.5 ton digital scroll. Therefore,

assembly is required in the OEM manufacturing plant.

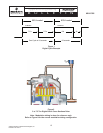

Figure 8 illustrates the correct position and orientation

of the modulation valve. Please note the direction of the

arrow on the valve, it must point to suction.

When brazing the modulation valve into the system,

the valve must be wrapped with a wet rag to help keep

thevalvecool.Thetorchamemustbedirectedaway

from the valve and the brazing operation should be

done quickly so the valve isn't overheated. The brazing

operation should be performed with a nitrogen purge to

prevent the build-up of copper oxide. The solenoid coil

should be installed after the brazing operation, so the

leads are kept away from the brazing operation and the

wet rag is able to fully contact the valve body.

Pressure Testing

The pressure used on the OEM assembly line to meet

the UL burst pressure requirement cannot be higher

than 400 psig (27.6 bar) for R-407C & R-22 and 475

psig (32.8 bar) for R-410A. Higher pressure may result

in permanent deformation of the compressor shell and

possibly cause misalignment or bottom cover distortion.