11

© 2012 Emerson Climate Technologies, Inc.

Printed in the U.S.A.

AE4-1395

Application Engineering

BULLETIN

9. Use care when handling the replacement

valve – don’t drop the valve or impact the

solenoid stem. If the valve is dropped or

damaged, discard it and obtain a new valve

for replacement.

10. Lightly oil the gaskets with refrigeration oil and

hand tighten the new modulation valve into the

valve receptacle on the compressor.

11. Using a 7/8” deep well socket and a torque wrench,

torque the modulation valve to 230 in-lbs.

12. Check for leaks using nitrogen with a properly

sized regulating and relief valve.

13. Install the solenoid coil and torque the retaining

screw to 25 in-lbs.

14. Install the terminal box cover, evacuate the

compressor/system, and put the system back into

operation.

NOTICE

The above procedures for changing the

modulation valve are comprehensive. Depending

on the equipment being serviced, additional steps

may be required. Refer to OEM instructions for

more information.

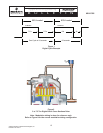

Copeland Scroll Compressor Functional Check

A functional compressor test with the suction service

valve closed to check how low the compressor will pull

suction pressure is not a good indication of how well a

compressor is performing. Such a test may damage a

scroll compressor. The following diagnostic procedure

should be used to evaluate whether a Copeland Scroll

compressor is working properly.

1. Propervoltagetotheunitshouldbeveried.

2. The normal checks of motor winding continuity

and short to ground should be made to determine

if the inherent overload motor protector has

opened or if an internal motor short or ground fault

has developed. If the protector has opened, the

compressormustbeallowedtocoolsufcientlyto

allow it to reset.

3. Proper indoor and outdoor blower/fan operation

shouldbeveried.

4. Remove power from the unloader solenoid to

load the compressor 100% . With service gauges

connected to suction and discharge pressure

ttings,turnonthecompressor.Ifsuctionpressure

falls below normal levels, the system is either low

onchargeorthereisaowblockageinthesystem.

5. If suction pressure does not drop and discharge

pressure does not rise to normal levels, reverse

any two of the compressor power leads (this

procedure is for 3-phase compressors only) and

reapply power to make sure compressor was not

wired to run in reverse direction. If pressures still

do not move to normal values, either the reversing

valve (if so equipped) or the compressor is faulty.

Reconnect the compressor leads as originally

conguredandusenormaldiagnosticprocedures

to check operation of the reversing valve.

The solenoid coil should only be energized

when it is installed on the solenoid valve.

Energizing the coil when it is not installed on

the valve will result in a failed coil.

Note: It is also possible that the unloader valve is

not closed. With the compressor off, cycle power

to the unloader solenoid and listen for clicking. If

no sound is heard the valve is very likely stuck.

6. To test if the compressor is pumping properly,

the compressor current draw must be compared

to published compressor performance curves

using the operating pressures and voltage of

the system. If the measured average current

deviates more than ±15% from published values,

a faulty compressor may be indicated. A current

imbalance exceeding 15% of the average on the

three phases should be investigated further. A

more comprehensive trouble-shooting sequence

for compressors and systems can be found in

Section H of the Emerson Electrical Handbook,

Form No. 6400.

7. Before replacing or returning a compressor: Be

certain that the compressor is actually inoperable.

As a minimum, recheck a compressor returned

from the eld in the shop or depot for Hipot,

winding resistance, and ability to start before

returning. More than one-third of compressors

returned to Emerson for warranty analysis

are determined to have nothing found wrong.

They were misdiagnosed in the eld as being

inoperable. Replacing working compressors

unnecessarily costs everyone.