www.controltechniques.com

9

Additional Software

CTOPC Server

OPC is the industry standard for connecting industrial

automation components to higher-level information systems

such as SCADA, MRP, ERP and others. Control Techniques’

CTOPC server is an OPC-compliant server that allows PCs to

communicate with Control Techniques drives via Ethernet,

CTNet, RS485 and USB. The OPC standard allows OPC clients

to browse data from an OPC server thus eliminating the

need for gateway data concentrators or proprietary drivers

and gateways. CTOPC server “serves” data to the various

OPC clients then polls data from all Control Techniques

components connected via Modbus RTU, Modbus TCP/IP or

CTNet.

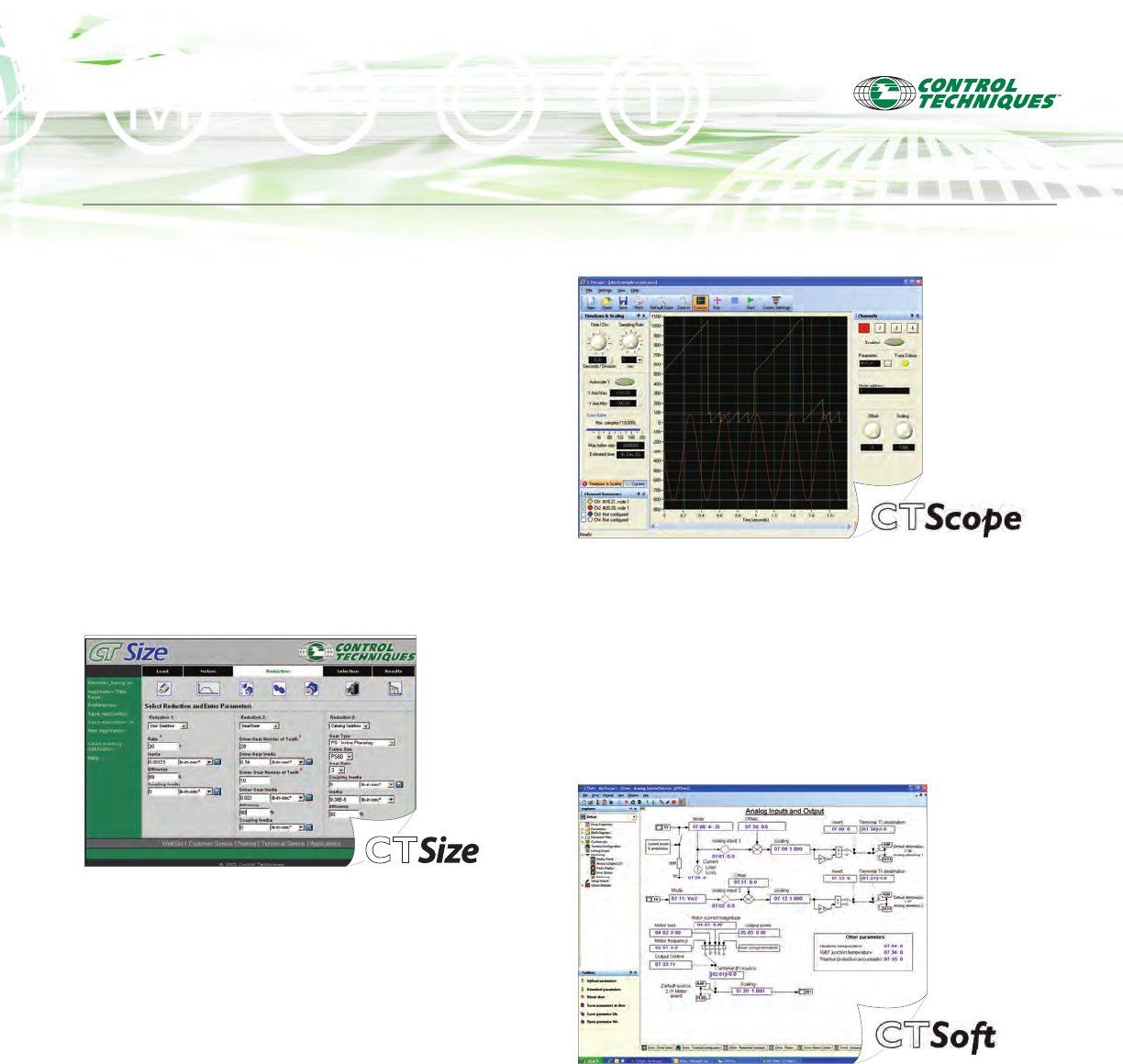

CTSize

This easy-to-use servo drive sizing software helps select the

optimum system in just six steps:

1. Select one of six pre-congured load types: Leadscrew,

Rack and Pinion, Conveyor, Cylinder, Feedroll and User

Dened.

2. Fill in the load details.

3. Enter the load’s motion prole, making use of prole-type

shortcuts or creating multi-segment proles.

4. Select speed reduction from Belt/Pulley, Gear/Gear,

Chain/Sprocket, or Gearbox for up to three separate

stages of reduction.

5. Select from all products or narrow the search to a specic

drive and/or motor.

The optimum motor/drive combination appears in the

Results tab.

CTScope

This Windows

®

-based software utility is designed to trend/

trace parameter values on Control Techniques drives and op-

tion modules. CTScope has the look and feel of a traditional

hardware oscilloscope and can plot up to four channels of

data simultaneously. All channel data appears in single-scope

view for easy comparison and CTScope les can be saved for

future use.

CTSoft

Control Techniques’ free drive conguration tool can be used

to commission, optimize and monitor Unidrive SP “Base”

drives. CTSoft uses wizards to simplify commissioning,

manages data stored on the SmartCard and features robust

and graphical tools for monitoring and troubleshooting. The

status of the program can be monitored and the speed of the

motion reduced for commissioning and testing purposes.