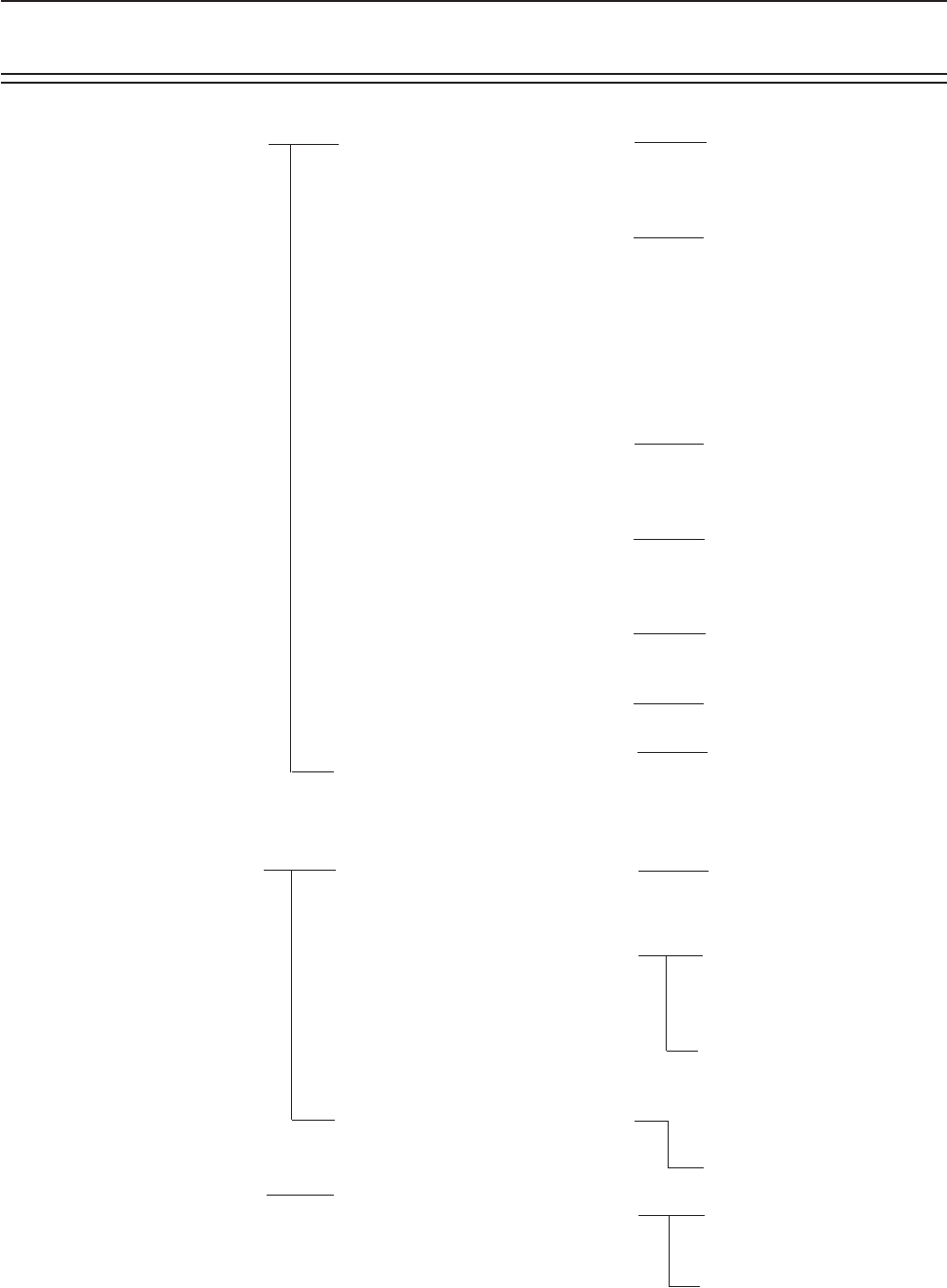

32

The actuator cannot be cali-

brated

The actuator goes into cali-

bration mode spontane-

ously

The actuator goes into cali-

bration mode every time

power is restored after a

power loss

Dirt or debris is blocking one or

both optocoupler slots

The photochopper fence extends

less than about half way into the

optocoupler slots

The white calibrate wire in the grey

Turck cable is grounded

Dirt and/or condensation on the

position sensor boards are causing

it to malfunction

The calibrate button is stuck

down

The position sensor has failed

Push button is being held down for

more that ¾ second when going

through the calibration procedure

The white calibrate wire in the grey

Turck cable is grounding intermit-

tently

A very strong source of electromag-

netic interference (EMI), such as a

contactor, is in the vicinity of the

actuator or grey cable

There is an intermittent failure of

the position sensor

The motor brake is not work-

ing properly (see theory section

above.)

Clean the optocoupler slots

with a Q-Tip and rubbing alco-

hol.

Adjust the photochopper so

that the fence extends further

into the optocoupler slots.

Make sure the motor brake

operates freely and the pho-

tochopper will not contact the

optocouplers when the shaft is

pressed down.

Tape the end of the white wire

in the panel and make sure that

it cannot touch metal

Clean the boards with an elec-

tronics cleaner or compressed

air.

Try to free the stuck button.

Replace the actuator.

Depress the button quickly and

then let go. Each ¾ second the

button is held down counts as

another press.

Tape the end of the white wire

in the panel and make sure that

it cannot touch metal.

Increase the distance between

the EMI source and the actua-

tor.

Install additional metal shield-

ing material between the EMI

source and the actuator or

cable.

Replace the actuator.

Get the motor brake to where it

operates freely and recalibrate.

Replace the actuator.

Slide Valve Actuator Trouble Shooting Guide

Problem Reason Solution