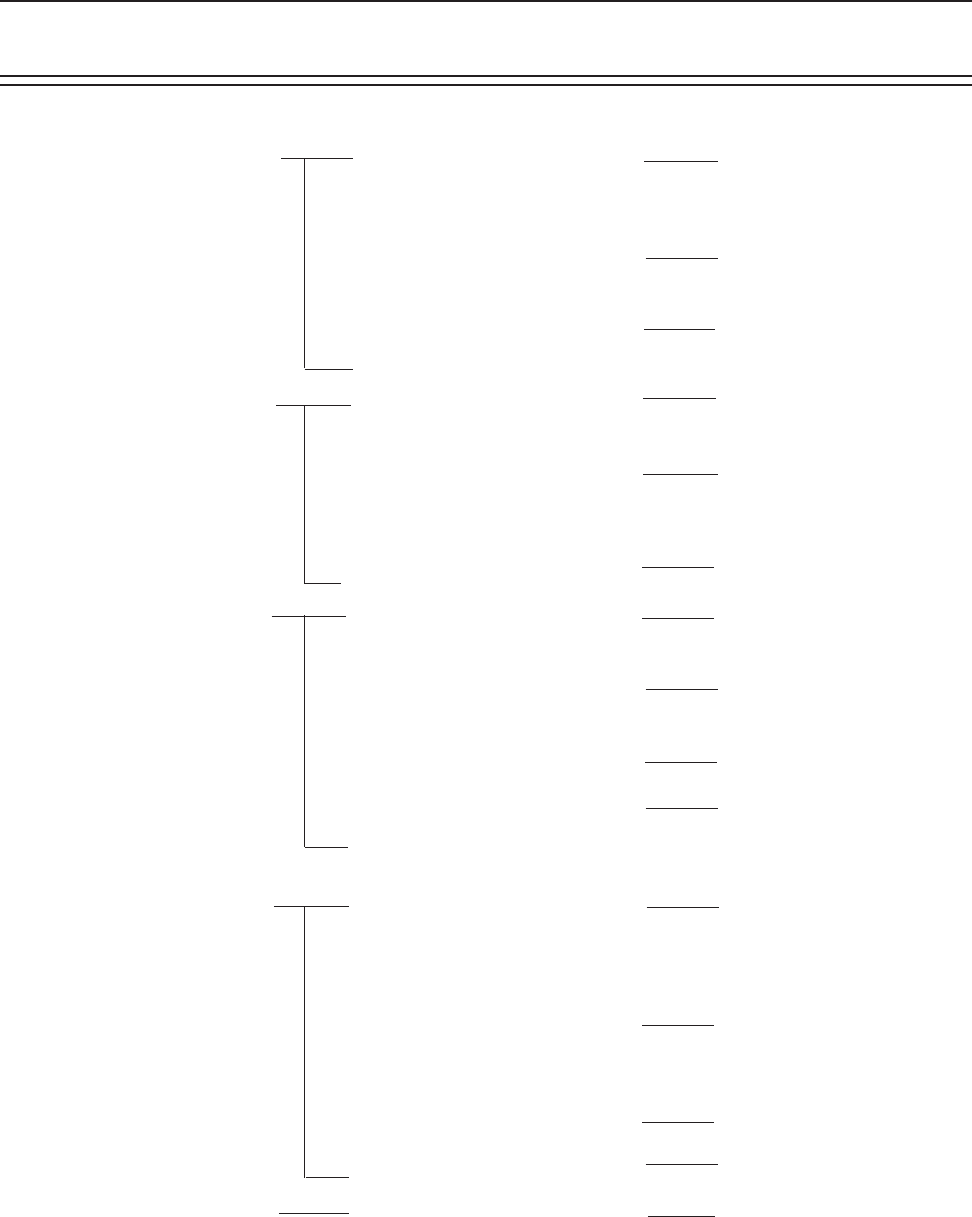

33

The motor was manually moved

while the position sensor was not

powered.

The motor brake is not working

properly

The position sensor’s EEPROM

memory has failed

The photochopper is misaligned

with the slotted optocouplers

The photochopper is positioned

too low on the motor shaft.

A motor bearing has failed

There is a loose connection in the

screw terminal blocks

There is a loose or dirty connec-

tion in the yellow Turck cable

The position sensor has failed

There is a broken motor lead or

winding

The thermal switch has tripped

because the motor is overheated

Any of the reasons listed in “The

motor operates in one direction

only”

The command shaft is jammed

Broken gears in the gearmotor

Motor is overheating and the

thermal switch is tripping

Recalibrate.

Get the motor brake to where it

operates freely and then recali-

brate.

Replace the actuator.

Try to realign or replace the ac-

tuator.

Adjust the photochopper so that

the fence extends further into

the optocoupler slots.

Replace the actuator.

Tighten.

Clean and tighten.

Replace the actuator.

Replace the actuator.

The motor will resume opera-

tion when it cools. This could be

caused by a malfunctioning con-

trol panel. Consult the factory.

See above.

Free the command shaft.

Replace the actuator.

This could be caused by a mal-

functioning control panel. Con-

sult the factory.

The actuator does not trans-

mit the correct position after

a power loss

There is a rapid clicking noise

when the motor is operat-

ing

The motor operates in one

direction only

The motor will not move in

either direction

The motor runs intermittently,

several minutes on, several

minutes off

Slide Valve Actuator Trouble Shooting Guide

Problem Reason Solution