71

DISCHARGE MANIFOLD INSTALLATION

A) Install (2) guide rods to position the discharge

manifold. Install a new manifold gasket and

the discharge manifold. Install the dowel pins

and bolts, tighten manifold bolts to the recom-

mended torque value.

B) On VSS 451-3001 compressors install the dis-

charge spool or elbow between the discharge

manifold and oil separator with new gaskets.

When installing the discharge elbow tighten

the bolts to the correct torque on the manifold

flange first before tightening the separator

ange bolts. Install the drain plug in the bottom

of the discharge manifold.

C) On VSM 301-701 compressors install the bolts

in the discharge ange. Install the drain plug in

the bottom of the discharge manifold.

D) Install both command shaft assemblies and

control actuators.

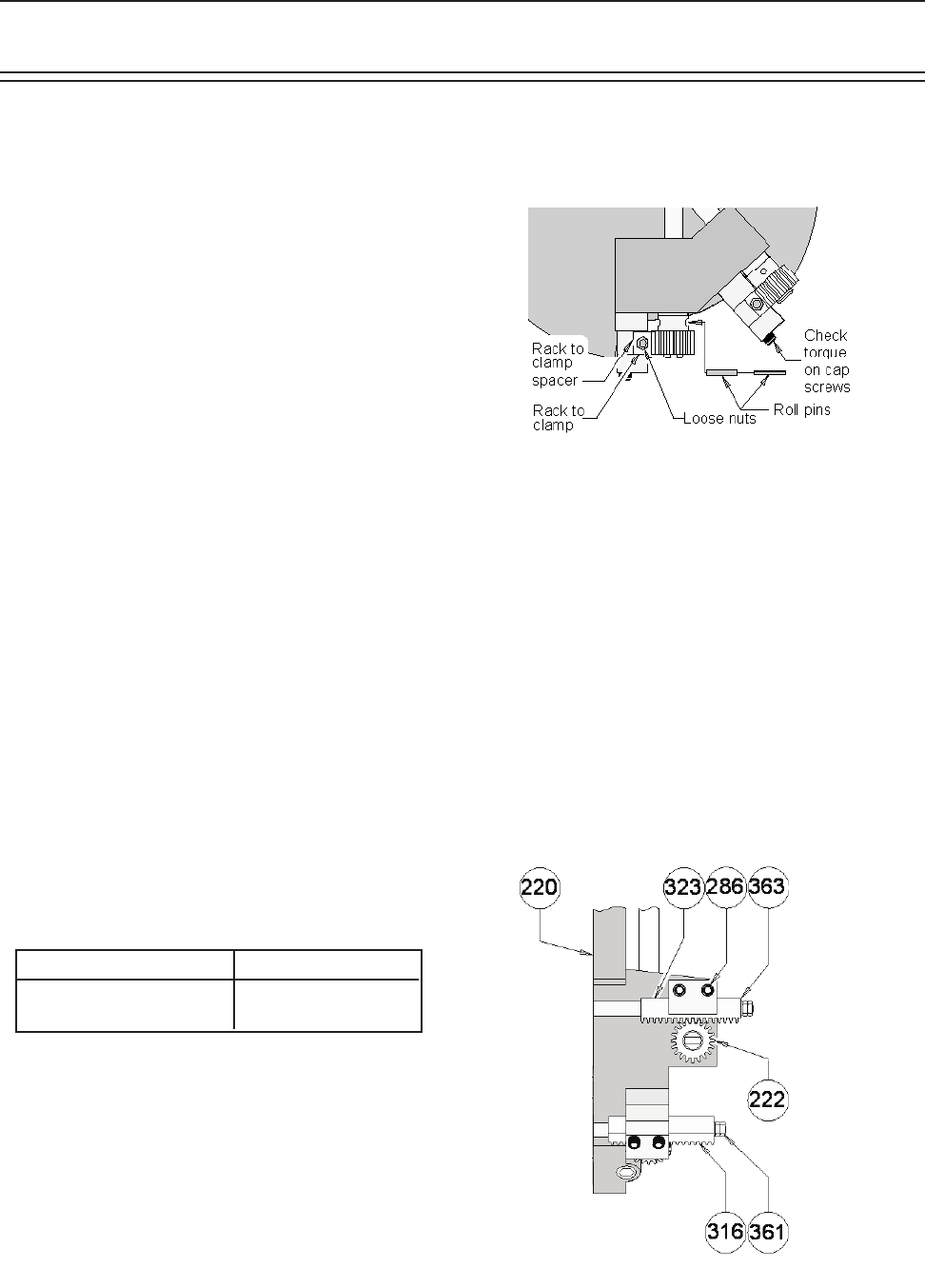

SLIDE VALVE GEAR AND RACK INSPECTION

A) Remove the discharge manifold.

B) Check rack to rack clamp and rack clamp spacer

clearance on all four slide valves.

TABLE 4.1

RACK CLEARANCE VALUES

C) Check torque of socket heat cap screws.

D) Check for excessive movement between the

slide valve rack shafts and the rack. The jam nuts

on the end of the slide valve rack shaft should be

tight.

E) Check for loose or broken roll pins in gears.

Service

F) Look for any excessive wear on all moving parts

and replace the worn parts.

G) Reassemble the manifold and discharge elbow.

REMOVAL OF CAPACITY OR VOLUME CROSS

SHAFTS

A) Remove the discharge manifold.

B) To remove the capacity or volume ratio slide

valve racks, remove the two jam nuts and lock

washers (361) securing the rack (316) to the slide

valve shafts. The racks can now be pulled off the

slide valve shafts. Repeat the procedure for the

remaining pair of slide valve racks.

MEASUREMENT CLEARANCE

Rack to clamp. 0.005 to 0.010”

Rack to clamp spacer. 0.003 to 0.005”