37

OIL SYSTEM

A. Oil Charge

Charge the oil separator with the proper quantity of

lubricating oil (see Table 2 in the Installation Section).

CAUTION

It is imperative you charge the oil into the receiver/

separator prior to energizing the control panel to

prevent burning out the immersion heater in the

separator/receiver.

During operation, maintain the separator oil level

in the normal operating range between the two

bullseye sight glasses. If the oil level is visible only

in the lowest sight glass, add oil to the operating

compressor through the connection located at the

compressor suction inlet. Pump oil into the compres-

sor until the oil level in the separator is between the

two bullseye sight glasses. Watch this level carefully

to maintain proper operation. Never allow the oil to

reach a level higher than indicated on the highest

sight glass, since this may impair the operation and

efficiency of the oil separator portion of this combi-

nation vessel.

B. Oil Filter

Change the oil filter after the first 200 hours of opera-

tion, as noted on the hour meter. Thereafter, replace

the filter every six months, or when the oil pressure

drop through the filter reaches 45 psi, whichever oc-

curs first. The pressure drop across the filter is read

on the microprocessor panel. Check the pressure

drop and record it daily.

To prepare for the removal of the filter, shut down

the compressor. Isolate the filter housing appropri-

ately. If unit is equipped with duplex filter housings

the unit does not have to be shut down, however

the filter to be serviced must be isolated before the

tank can be opened.

1. Filter Removal, VSG Units using Vilter Part

Number1833Coillterelements.

Release the pressure in the oil filter housing by

opening the bleed valves at the stop valve in the

block and bleed assembly, or at the bleed valve

for the oil filter housing. Be sure to follow all

Local, State, and Federal ordinances regarding

the recovery of refrigerants.

Drain the filter housing in to an appropriate

container and dispose of the oil in a appropriate

manner following all Local, State and Federal

ordinances regarding the disposal of used oil.

Unscrew the bolts holding the cover flange to

the tank. Remove the cover flange and spring

plate. Pull out the filter element(s). Before

reassembling, thoroughly clean the tank and

spring plate to lengthen the life span of the filter

element(s).

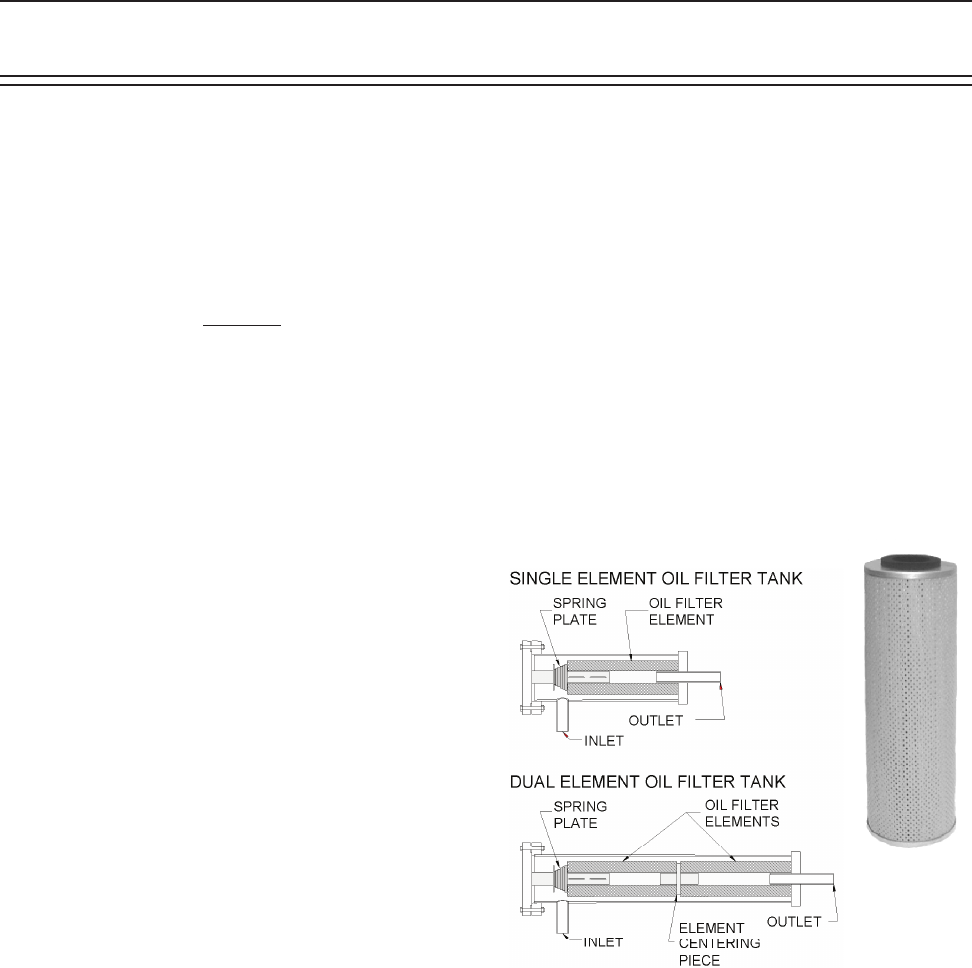

FIGURE 1.

1833C FILTER ELEMENT TANKS

To replace the filter element(s), on single ele-

ment tanks, insert the element and make sure

it fits onto the outlet connection. Install spring

plate, and bolt the cover assembly in place. On

units equipped with dual element tanks, insert

inner element and make sure it fits onto the

outlet connection. Put the centering piece on

the outer element and slide into tank making

sure the center piece fits into the inner element.

Put spring plate on outer element and bolt the

cover assembly in place.

Operation

1833C

Filter

Element