38

2. Filter Removal and installation, all

VSR Units.

Release the pressure in the oil filter housing by

opening the bleed valves at the stop valve in the

block and bleed assembly, or at the bleed valve

for the oil filter housing. Be sure to follow all Lo-

cal, State and Federal ordinances regarding the

recovery of refrigerants.

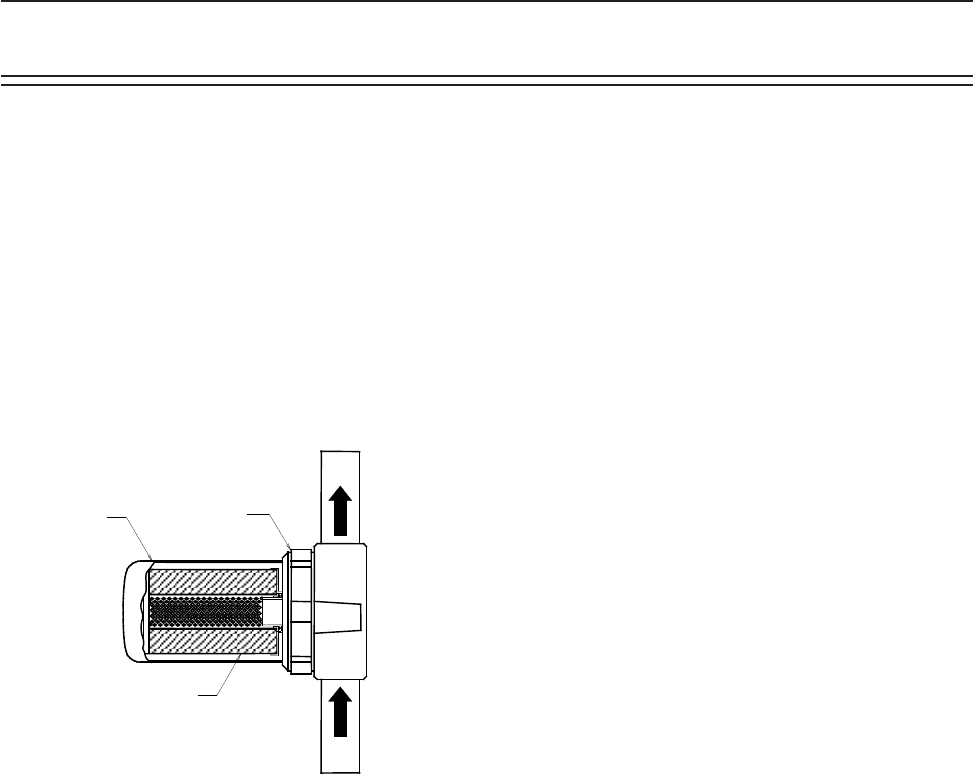

FIGURE 2.

TYPICAL CANISTER TYPE FILTER CROSS SEC-

TION

Drain the filter bowl or housing in to an appro-

priate container and dispose of the oil in a ap-

propriate manner following all Local, State and

Federal ordinances regarding the disposal of used

refrigeration oil.

Loosen and remove the locking ring on filter tank

by turning in a counter clockwise direction. Re-

move filter tank with the used element.

Remove the filter element from the tank. Be-

fore reassembling, thoroughly clean the tank to

lengthen the life span of the filter element.

Wet the threads and O-ring on the head and the

O-ring in the new element with clean refrigera-

tion oil.

CAUTION

Do not use a pipe wrench, hammer or any other tool

to tighten the locking ring.

nsert new element into the filter tank with

the open end visible. Attach tank to head and

HAND TIGHTEN the locking ring.

The filter housing can be evacuated and then

slowly pressurized to check for leaks before

returning to service.

3. Filter Removal, VSS and VSM Units

(after 5/1/00) when using Vilter Part

Numbers 3111A (16” Simplex), or

3112A (39” Simplex) oil filter

housings.

Release the pressure in the oil filter housing by

opening the bleed valves at the stop valve in

the block and bleed assembly, or at the bleed

valve for the oil filter housing. Be sure to follow

all Local, State and Federal ordinances regard-

ing the recovery of refrigerants.

Drain the filter bowl or housing in to an ap-

propriate container and dispose of the oil in a

appropriate manner following all Local, State

and Federal ordinances regarding the disposal

of used refrigeration oil.

Loosen and remove the cover on the bowl of

the filter tank by turning it in a counter clock-

wise direction. Remove the used element.

Wet the O-ring in the new element with clean

refrigeration oil. Insert the new element into

the filter tank with the closed end visible and

attach the cover to the bowl. HAND TIGHTEN

the cover.

The filter housing can be evacuated and then

slowly pressurized to check for leaks before

returning to service.

LOCKING

RING

FILTER

ELEMENT

FILTER

TANK

INLET

OUTLET

Operation