39

4. Filter Removal, VSS and VSM Units (after

5/1/00) when using Vilter Part Numbers

3109A (16” Duplex), or 3110A (39” Du

plex) oil filter housings.

Isolate the bowl to be worked on by turning

handle. The handle will cover the drain valve of

active element. Close commuter valve in center of

handle. Release the pressure in the isolated bowl

by bleeding through the stop valve on the oil filter

cover for Duplex (Vilter Part #3109A or 3110A),

or through the stop valve for the oil filter hous-

ing. Be sure to follow all Local, State and Federal

ordinances regarding the recovery of refrigerants.

Drain the filter bowl or housing in to an appro-

priate container and dispose of the oil in a ap-

propriate manner following all Local, State and

Federal ordinances regarding the disposal of used

refrigeration oil.

Loosen and remove the cover on the bowl of the

filter tank by turning it in a counter clockwise

direction. Remove the used element.

Wet the O-ring in the new element with clean

refrigeration oil. Insert the new element into the

filter tank with the close end visible and attach

the cover to the bowl. HAND TIGHTEN the cover.

The filter housing can be evacuated and then

slowly pressurized by opening the commuter

valve on handle. This will pressurize the housing.

Check for leaks. The filter can now be returned

to service. Repeat for other filter bowl if needed.

CAUTION

When changing filter, discard clogged filter only. Save

and reuse spring plate and centering piece. This filter

MUST be installed with the spring plate. A compressor

that is allowed to operate without the spring plate is

running with unfiltered oil.

The filter housing can be evacuated and then

slowly pressurized to check for leaks before re-

turning to service.

C. Oil Pressure Regulating

On units with a full time oil pump, the back pres-

sure regulator, in the oil supply line from the sepa-

rator, controls upstream pressure to the compres-

sor bearings and should be adjusted to hold the oil

pressure at 50 psig above suction pressure. Excess

oil not required for bearing lubrication is passed

through the regulator and flows into the separator.

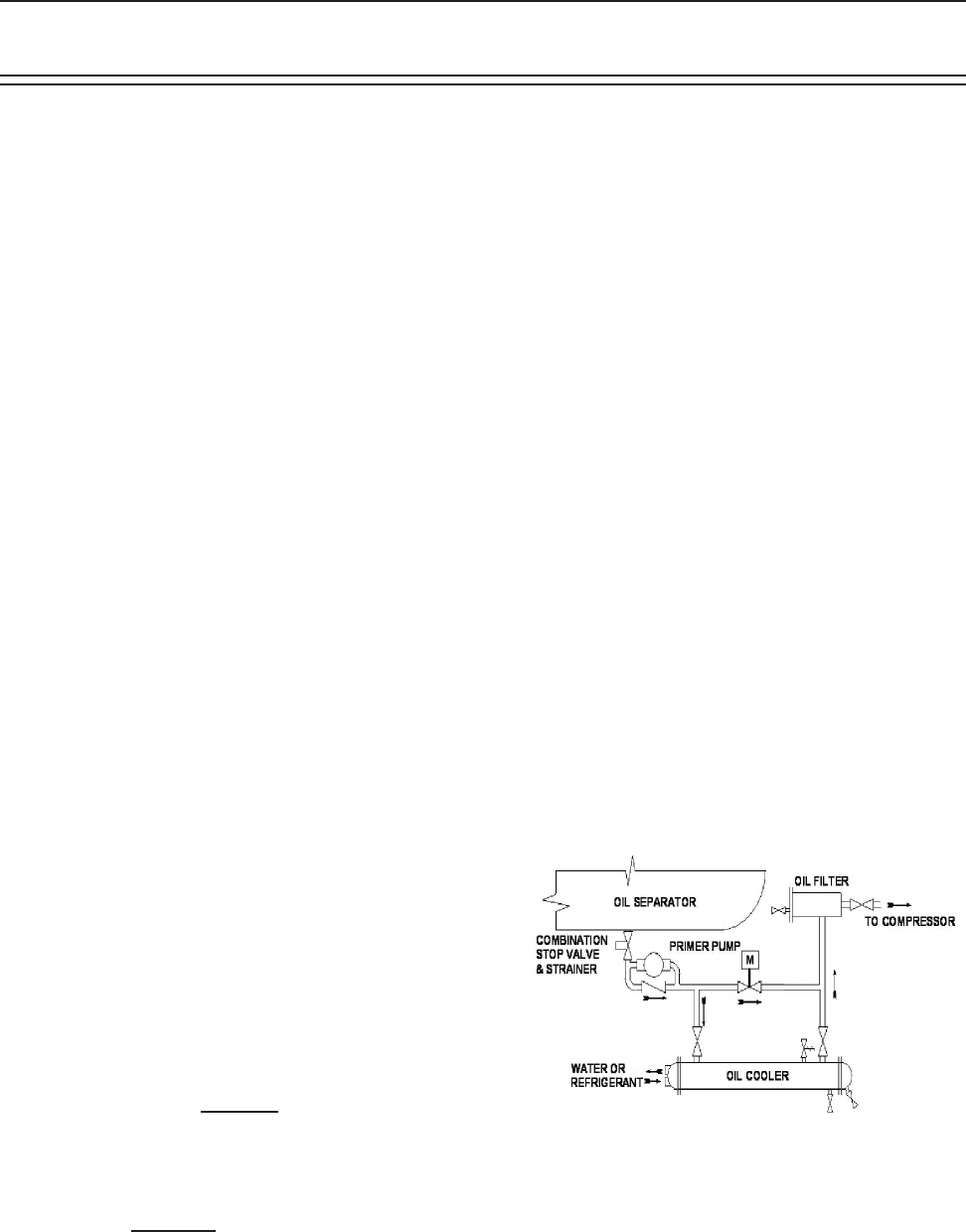

D. Oil Cooling

Various types of oil coolers can be used to main-

tain the oil injection temperature, usually either

a water-cooled shell-&-tube heat exchanger

mounted locally or a remotely located air-cooled

fan-coil unit. In either case, the oil temperature

control valve operates the same. (See Appendix

A: Pre Start Up for Remote Oil Coolers)

A two-way ball valve is located in the main oil line

between the oil separator and the compressor.

The oil cooler is piped in parallel to the oil tem-

perature control valve, which acts as a by-pass

valve (Figure 3).

FIGURE 3.

TYPICAL WATER COOLED OIL COOLER DIAGRAM

1. Temperature Control Valve Installation

& Position Indication

1.1 The ball valve is installed with the ball

closed.

Operation