Page|13

ENERGIZERBATTERYMANUFACTURING

VERSION1.2

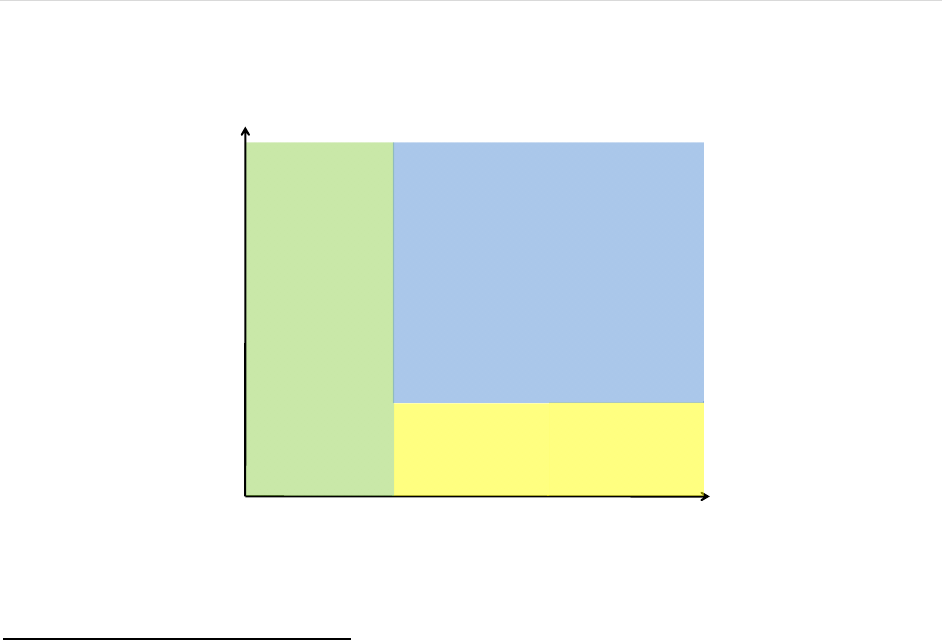

Figure11:OverviewofDifferentAirManagementTechniques

high

low

continuous inter mittent

noneorsmall

degreeofair

management

needed,sincecell

capacityisquickly

used

(1‐3months)

highdegreeofairmanagementneeded,

cellhashighairaccessbutisexpectedto

beinservicewithlongperiodsof“off”

time(>3months)

DutyCycle

Discharg eRate

throttlingneededto

maximizeservice

time(>3months )

3.2‐‐ElementsofAirManagement

Twoelementsofasuccessfulin‐deviceairmanagementsystemareameansforallowingcontrolledair

accesstothebatteryandanairplenumforevenairdistribution.Anairplenumisanairgap,orvolume,

which has access to all of the air holes on the battery.

The air plenum allows for more even air

distribution over the battery air holes, and it provides a reserve of air immediately available to the

batterytohandlepeakpowerneeds.Controllingairaccesstothebatteryisaccomplishedbycreatingan

access path to the sealed volume of air within

a device.The air access path is designed to allow a

desired amount of air to flow to the sealed volume of air, which includes the plenum, either

continuously or intermittently.A sealed volume of air can be created by sealing an entire device, a

portionofthedeviceincluding

thebatterycompartment,orjustaplenumabovetheairholesideofthe

battery.Thepowerrequirementsofthedevicedeterminetherateatwhichairisrequiredtoflowtothe

battery.

Figure 12 illustrates a simple, cost effective air management solution designed into a device.The

compartmentdoorcontainsano‐ringwhichsealsagainsttheairholesideofthebatterywhenthedoor

isclosed.Theairplenu mvolumeisdefinedbythecompartmentdoorandthesidesof the

o‐ring.A

slideswitchislocatedinthecompartmentdoortocreateanairaccesspoint.Theslideswitchactsasa

valvewhich seals thecompartment when inthe closedposition andallows air toflow tothe battery

when in the open position.The slide switch could

be mechanically manipulated by the user or

electronicallycontrolledbythedevice.