4. After the cut is complete, unplug the saw for safety, but

leave it on the guide rail.

5. Lower the sawblade to its maximum depth and examine

the gap between the blade and the workpiece using a

regular piece of paper as a thickness gauge.

► The front of the blade should be tight to the workpiece.

You should not be able to slip the paper between the blade

and workpiece.

► The rear of the blade should be 0.15mm away from the

workpiece. The paper should fit loosely between the blade

and workpiece, but two sheets of paper should not fit.

6. If an adjustment is necessary, loosen the rear bevel

locking knob and move the back of the saw until the

0.15mm gap is achieved.

7. Retighten the bevel locking knobs before removing the

saw from the guide rail, and then retighten the other

screws. (Set the bevel pointer to zero before tightening

the screw.)

Replacing the Splinter Guard

The splinter guard prevents splintering and chipping of the

workpiece by holding the top edge of the workpiece down as the

teeth of the sawblade move upward against it. The splinter guard

needs to be replaced if it becomes damaged or worn.

Because the splinter guard is trimmed by the sawblade, it is important

that the sawblade is properly adjusted before replacing the splinter

guard. Verify and/or perform the "Adjusting the Blade Position"

procedure described on page 10 before replacing the splinter guard.

Instruction Manual 11

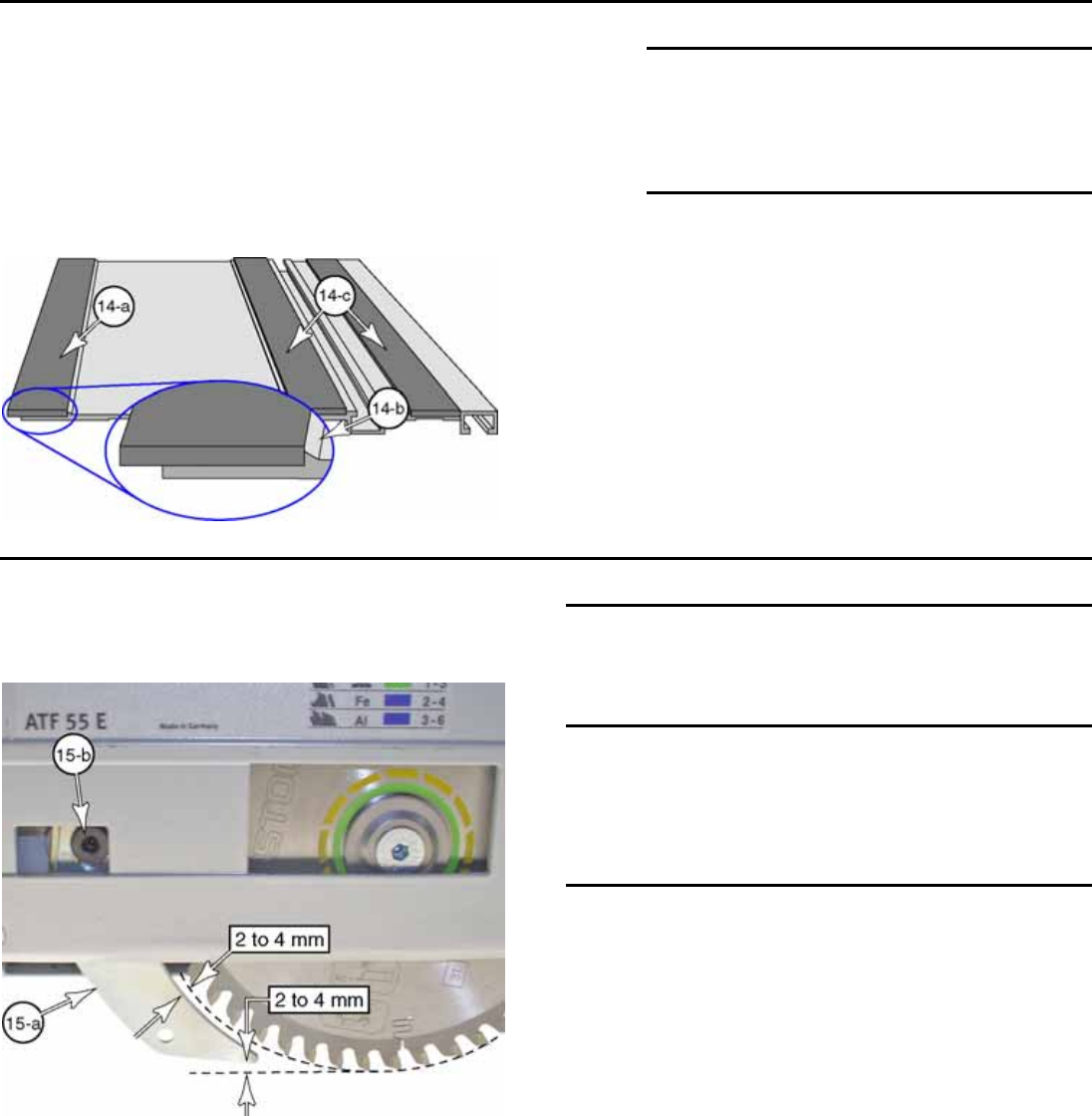

Figure 14

14-a Splinter Guard

14-b Alignment Rib

14-c Friction Strips

Replacement Procedure

1. Peel the original splinter guard away from the

guide rail.

2. As needed, clean residual adhesive and debris

from the guide rail.

3. Peel off the plastic backing from the new

splinter guard to expose the adhesive.

4. Without stretching the rubber, carefully place

the new splinter guard on the underside of the

guide rail tight to the alignment rib (14-b).

5. Make sure the splinter guard is firmly pressed

down to the guide rail.

6. Trim the splinter guard as described on page 8.

Removing/Replacing/Adjusting the Riving Knife

The riving knife must be removed before a plunge cut can be

made. After it is reinstalled, it must be adjusted for proper

clearance.

Figure 15

15-a Riving Knife

15-b Adjustment Screw

Removal Procedure

1. Unplug the saw.

2. Loosen the adjustment screw (15-b).

3. Remove the riving knife and retighten the adjustment

screw.

Replacement/Adjustment Procedure

1. Unplug the saw.

2. Loosen the adjustment screw (15-b).

3. Insert the riving knife under the adjustment screw.

4. Move the riving knife to achieve the clearance from the

blade as shown in figure 15.

5. Tighten the adjustment screw.