Plunge Routing

Plunge routing is any operation where the router is

lowered down into the cutting area after the router has

been started. Most often this involves router bits that do

not have a guide bearing, but can also be used for interior

cutting (such as the circular cut shown on page 12).

Instruction Manual 13

!WARNING: Take care while plunge routing to maintain

control of the router at all times. For many plunge

operations, one side of the router bit will be climb-

cutting and the other side will be push-cutting. This

can lead to a loss of control and/or poor cut quality.

1. Verify that the router bit is properly secured and the

router is ready for operation.

2. Secure the workpiece to a stable surface.

3. Set the router speed according to the speed settings

table below.

4. With the router turned off, place the router on the

workpiece.

5. Firmly grasp both handles of the router and pull up on the

power switch.

6. Lower the router to the desired depth, tighten the plunge

lock knob, and advance the router through the cut.

!WARNING: Failure to tighten the plunge lock knob may

result in a loss of control and injury.

► For router bits with guide bearings, advance the router

through the cut according to the feed direction rules

discussed on page 12.

► When using router bits without a guide bearing, or with an

external guide rail, follow the tips in "plough cuts" below

to keep the router tracking properly.

Plough Cuts

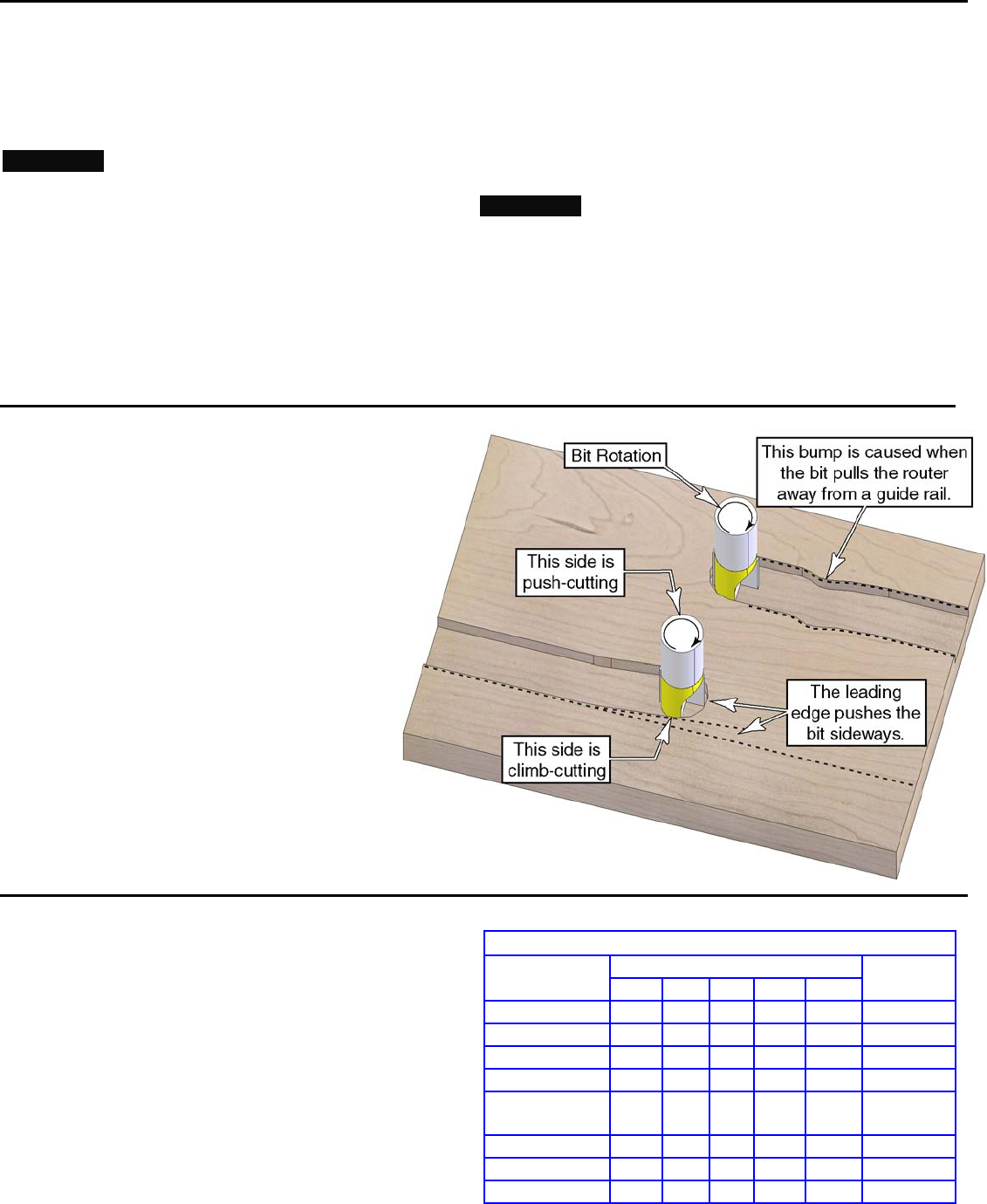

When making plough cuts, as shown to the right,

three sides of the router bit are engaging the

workpiece. This can lead to undesired changes in

the path of the router.

► One side of the router bit is climb-cutting, and

this tends to propel the router forward.

► One side of the router bit is push-cutting, and

this tends to slow the feed rate.

► The leading edge of the router bit pushes the

router sideways, opposite the rotation of the bit.

The opposing climb-cutting and push-cutting sides

will cause the router to advance with a jerking

motion.

To avoid drift from the leading edge of the router

bit, position a guide rail on the push-cutting side of

the router (toward the middle in the image to the

right).

Router Speed and Feed Rate

The optimal router speed for an operation is determined

by the diameter of the router bit and the type of material

being machined. The important factor is the speed that the

router bit tips move past the workpiece. The tip speed is

proportional to the diameter of the router bit.

If the tip speed is too high, friction causes excessive heat

and the workpiece can be scorched. Too low of a tip speed

and the bit will tear the material instead of cutting (for

aluminum, the bit will grab the workpiece).

The feed rate of the router past the workpiece is a function

of the router speed, material type, and amount of material

being removed. Too fast of a feed rate can cause chatter

and tearout. Too slow of a feed rate can burn or scorch the

workpiece.

Router Speed Settings

Bit Diameter (inches)

Material

≤½ ¾ 1 1¼ ≥1½

Feed

Rate

Pine

5-6 5-6 4-6 3-5 3-5 Fast

Oak

5-6 4-6 4-5 3-5 2-4 Moderate

Cherry

3-5 3-5 3-4 2-4 2-3 Moderate

Maple

3-5 3-5 3-4 2-4 2-3 Slow

Particleboard

and MDF

5-6 5-6 4-6 3-5 3-5 Fast

Soft Plastics

3-5 3-5 3-4 2-4 1-3 Slow

Hard Plastics

2-4 1-4 1-3 1-2 1-2 Slow

Aluminum

3-4 3-4 2-3 2-3 1-3 Slow