1.

Always

stop

the

pump

a

the

bottom

of

Its

stroke

when you take a break and at the end

of

the

day. This

helps keep fluid from drying on the rod

and damaging the packings.

2.

Keep

the

displacement

pump

packing

nut/wet-cup

1/4

full

of

TSL at

all

times. The TSL

helps

protect the packings and rod.

3.

Check

the

tightness

of

the

packing

nut

daily.

It

should be tight enough to stop leakage,

but

no

tighter. Overtightening will damage the packings.

------CAUTION------

Proper engine and hydraulic oil level

is

important

to prevent

costly damage

to

the sprayer. Check it

as

often

as

recommended

in

Steps 4 and 5, below.

4.

Check

tha

hydraulic

oil

level

weekly.

The oil

must be up

to

the top mark on the dipstick (25).

Use

only Graco Hydraulic Oil,

see

ACCESSORIES.

5.

Check

the

engine

oil

level

at

least

weekly.

The

oil must

be

up

to

the top mark on the dipstick with

the fill cap unthreaded.

The

engine should not

use

more than one ounce

of

oil per hour

of

operation.

Consult the engine manual, supplied, for additional

recommended maintenance.

6.

Inspect

the

return

line

filter. (65)

frequently

for

clogging. Replace it after every

500

hours

of

opera-

tion or every six months, whichever comes first. A

clogged or worn

out

filter reduces filter capability

and will damage the hydraulic pump.

7.

Change

the

hydraulic

oil

after

every

2000 hours

of

operation or every

12

months, whichever comes

first. For continuous operation in temperatures

above 85°F (30°C), change the oil after every 1000

hours or six months

of

use.

Refer to Step 8

for

pro-

cedure.

------CAUTION

-----

.......

Cleanliness

is

essential when servicing the

hydraulic system.

Use

special care

to

avoid get-

ting dust or dirt into the hydraulic system to pre-

vent damage to the

hydraulic components.

10 307-293

8.

To

change

the

hydraulic

oil:

a.

Follow the Pressure Relief

Procedure

Warn-

Ing,

on

page 8. Allow the oil to cool before pro-

ceeding.

b.

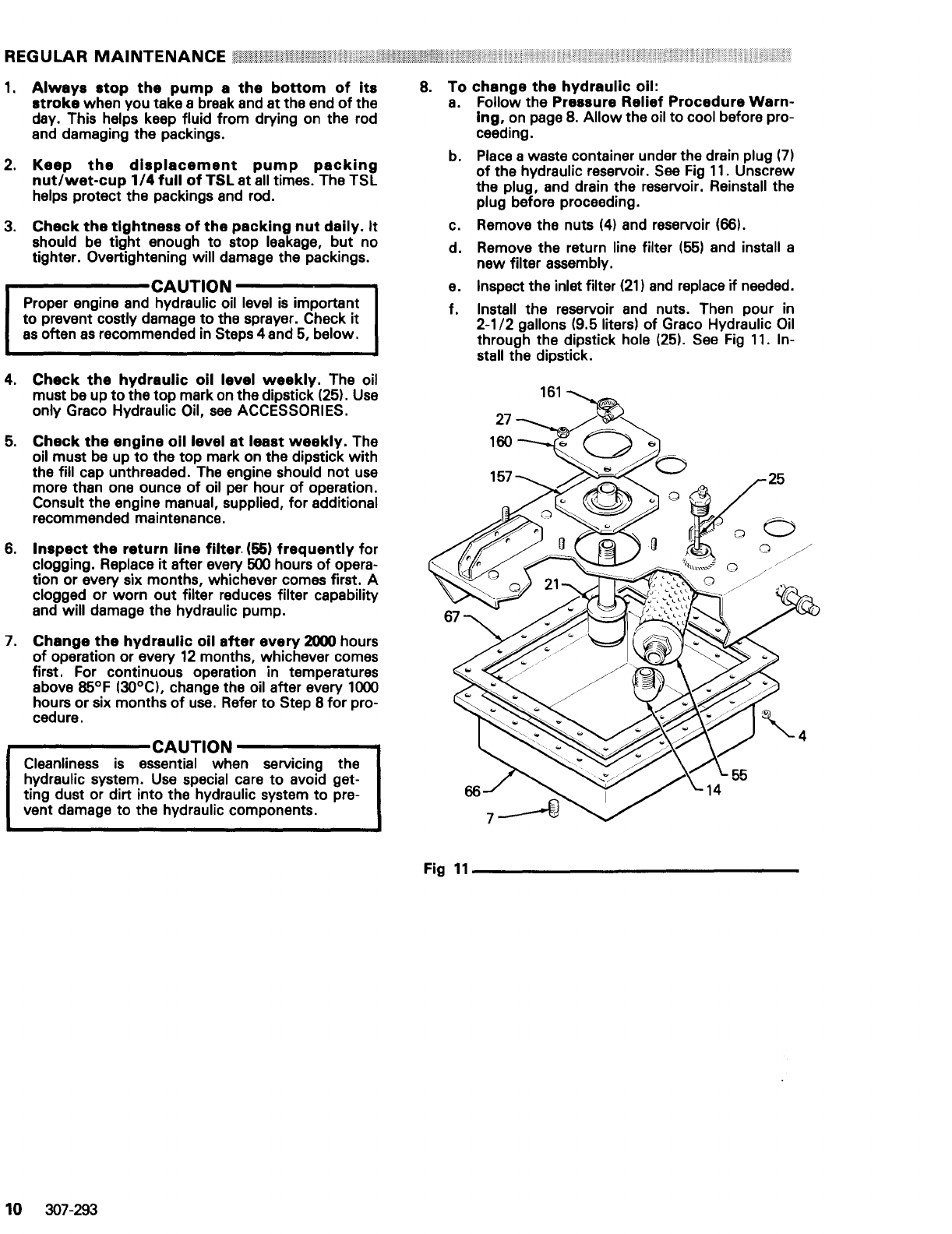

Place a waste container under the drain plug (7)

of

the hydraulic reservoir.

See

Fig

11. Unscrew

the

plug, and drain the reservoir. Reinstall the

plug before proceeding.

c.

Remove the nuts (4) and reservoir (66).

d. Remove the return line filter (55) and install a

new filter assembly.

e. Inspect the inlet filter (21)

and

replace

if

needed.

f. Install the reservoir and nuts. Then pour

in

2-1/2

gallons (9.5 liters)

of

Graco Hydraulic

Oil

through the dipstick hole (25),

See

Fig

11. In-

stall

the dipstick.

Fig

11

_______________

_