4. Fill

the

Packing

Nut/Wet

Cup

(141)

1/4

full with

Graco Throat

Seal

Liquid nsu, supplied.

5.

Check

the

Hydraulic

Oil Level

a.

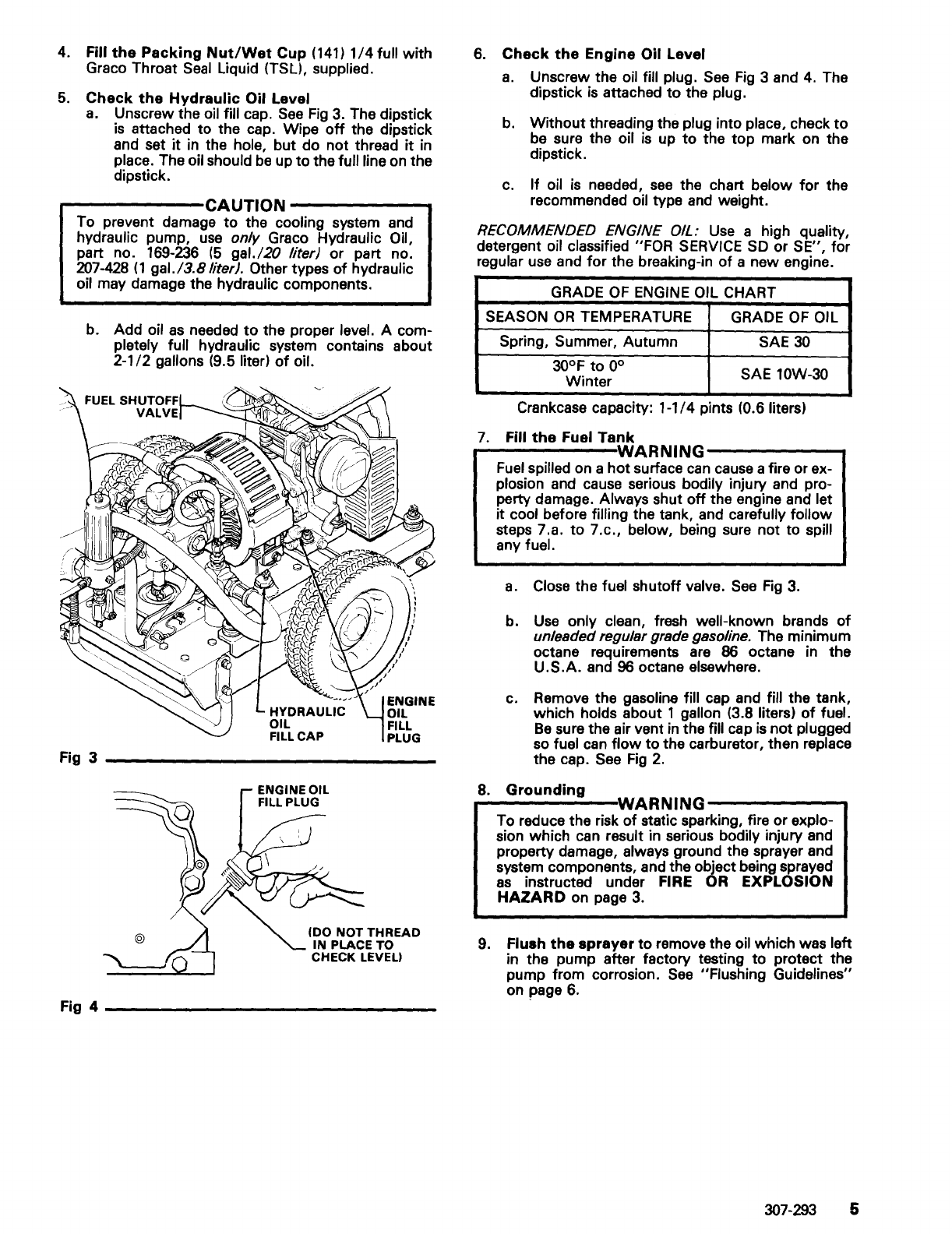

Unscrew the oil fill cap.

See

Fig

3.

The dipstick

is

attached

to

the cap. Wipe

off

the dipstick

and set

it

in the hole, but do not thread

it

in

place. The

oil should

be

up

to

the full line on the

dipstick.

------CAUTION

------..,

To prevent damage

to

the cooling

syster:n

a~d

hydraulic pump,

use

only Graco Hydraulic

011,

part no. 169-236

(5

gal.l20

liter) or part

nc.>.

207-428

(1

gaI.l3.8Iiter).

Other types

of

hydraulic

oil

may damage the hydraulic components.

b. Add

oil

as

needed

to

the proper level. A com-

pletely full hydraulic system contains about

2-1/2 gallons (9.5 liter)

of

oil.

HYDRAULIC

OIL

FILL

CAP

Fig 3

_______________

_

@

ENGINE OIL

FILL

PLUG

100

NOT THREAD

IN PLACE TO

CHECK

LEVEll

Fig 4

_______________

_

6.

Check

the

Engine

Oil Level

a.

Unscrew the oil fill plug.

See

Fig

3 and 4. The

dipstick

is

attached

to

the plug.

b.

Without

threading the plug into place, check

to

be sure the oil

is

up

to

the

top

mark on the

dipstick.

c.

If oil

is

needed,

see

the chart below

for

the

recommended

oil type and weight.

RECOMMENDED ENGINE

OIL:

Use

a high quality,

detergent

oil classified "FOR SERVICE

SO

or

SE",

for

regular use and

for

the breaking-in

of

a new engine.

GRADE

OF

ENGINE

OIL CHART

SEASON

OR

TEMPERATURE

GRADE

OF

OIL

Spring, Summer,

Autumn

SAE

30

30°F

to

0°

SAE 10W-30

Winter

Crankcase capacity:

1-1/4 pints (0.6 liters)

7.

Fill

the

Fuel

Tank

.-------WARNING-----

...

Fuel

spilled on a

hot

surface

can

cause a fire or ex-

plosion and cause serious bodily injury and pro-

perty

damage. Always shut

off

the engine and let

it

cool before filling the tank, and carefully follow

steps 7.a.

to

7.c., below, being sure not

to

spill

any

fuel.

a. Close the fuel shutoff valve.

See

Fig

3.

b.

Use

only clean, fresh well-known brands

of

unleaded regular grade gasoline. The

mi~imum

octane requirements are 86 octane

In

the

U.S.A.

and 96 octane elsewhere.

c. Remove the

gasoline fill cap and fill the tank,

which

holds about 1 gallon (3.8 liters)

of

fuel.

Be

sure the air vent in the fill cap

is

not

plugged

so

fuel can

flow

to

the carburetor, then replace

the cap.

See

Fig

2.

8.

Grounding

WARNING-----

...

To reduce the risk

of

static sparking, fire or explo-

sion which can result in serious bodily injury and

property damage, always ground the

~prayer

and

system components, and the object being sprayed

as

instructed under FIRE OR EXPLOSION

HAZARD

on page

3.

9.

Flush

the

sprayer

to

remove the oil which was left

in the pump after factory testing

to

protect the

pump from corrosion.

See

"Flushing Guidelines"

on page

6.

307-293 5