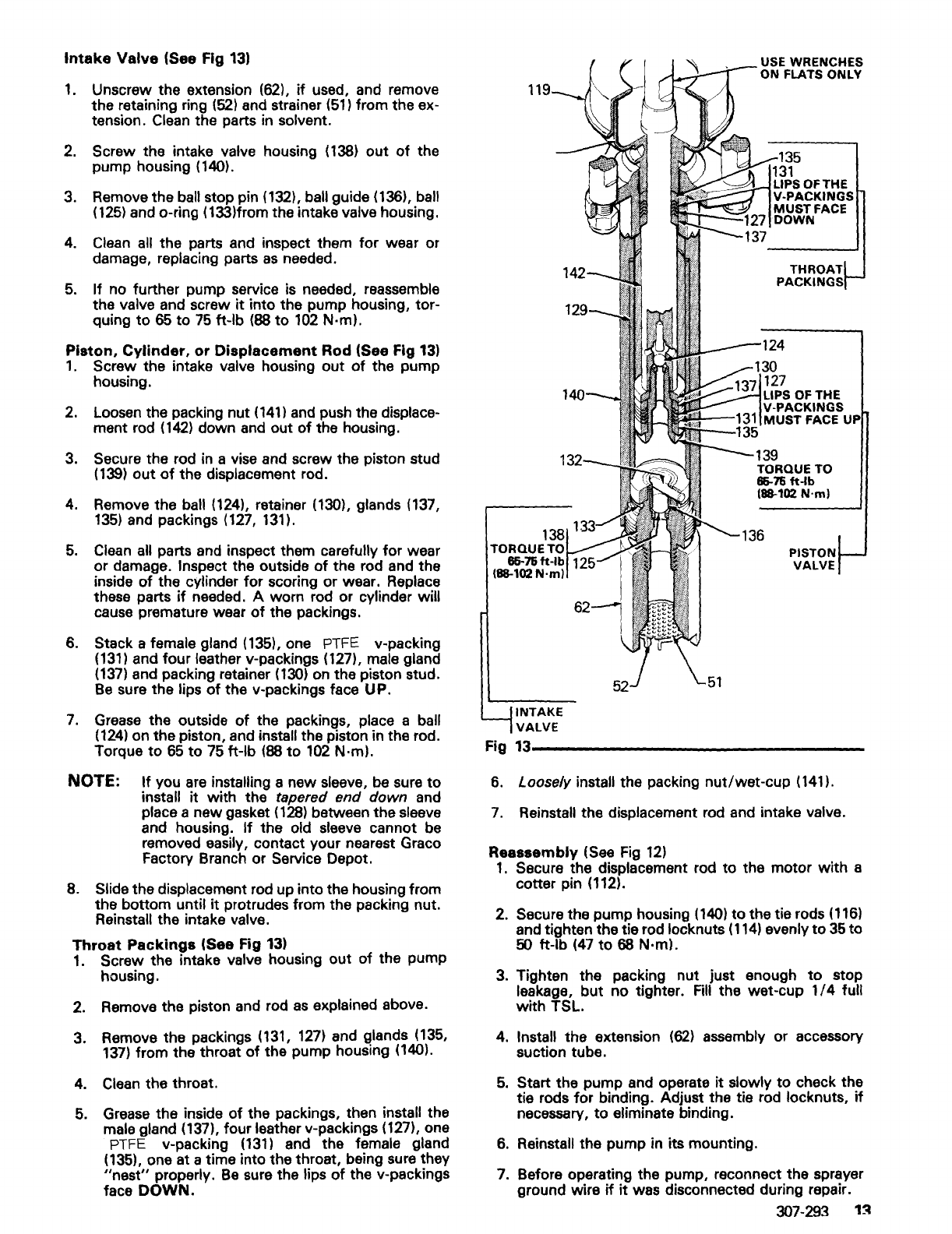

Intake

Valve

(See Fig

13)

1.

Unscrew the extension (62),

if

used, and remove

the retaining ring

(52) and strainer

(51)

from the ex-

tension. Clean the parts

in

solvent.

2.

Screw the intake valve housing

(138)

out

of

the

pump housing (140).

3. Remove the

ball stop pin (132), ball guide (136), ball

(125)

and o-ring (133)from the intake valve housing.

4.

Clean

all the parts and inspect them

for

wear or

damage, replacing parts

as

needed.

5.

If no further pump service is needed, reassemble

the

valve and screw

it

into the pump housing, tor-

quing

to

65

to

75

ft-Ib (88

to

102

N·m).

Piston,

Cylinder,

or

Displacement

Rod (See Fig

13)

1.

Screw the intake valve housing

out

of

the pump

housing.

2.

Loosen the packing nut

(141)

and push the displace-

ment rod

(142)

down and out

of

the housing.

3. Secure the rod

in

a vise and screw the piston stud

(139)

out

of

the displacement rod.

4.

Remove the ball (124), retainer (130), glands (137,

135)

and packings

(127,

131).

5.

Clean

all parts and inspect them carefully

for

wear

or damage. Inspect the outside

of

the rod and the

inside

of

the cvlinder

for

scoring or wear. Replace

these parts

if

needed. A worn rod or cylinder will

cause premature wear

of

the packings.

6.

Stack a female gland (135), one PTFE v-packing

(131)

and four leather v-packings (127), male gland

(137)

and packing retainer

(130)

on

the piston stud.

Be

sure the lips

of

the v-packings face UP.

7.

Grease

the outside

of

the packings, place a ball

(124)

on the piston, and install the piston in the rod.

Torque

to

65

to

75 ft-Ib (88

to

102

N·m).

NOTE:

If

you

are

installing a new sleeve, be sure

to

install it with the tapered end down and

place a new gasket

(128)

between the sleeve

and housing.

If

the old sleeve cannot be

removed easily, contact your nearest Graco

Factory Branch or

Service Depot.

8. Slide the displacement rod up into the housing from

the bottom until

it

protrudes from the packing nut.

Reinstall the intake valve.

Throat

Packings

(See Fig

13)

1.

Screw the intake valve housing out

of

the pump

housing.

2. Remove the piston and rod

as

explained above.

3. Remove the pac kings

(131,

127)

and glands (135,

137)

from the throat

of

the pump housing (140),

4.

Clean

the throat.

5. Grease the inside

of

the packings, then install the

male gland (137), four leather v-packings (127), one

PTFE v-packing

(131)

and the female gland

(135), one at a time into the throat, being sure they

"nest"

properly.

Be

sure the lips

of

the v-packings

face

DOWN.

INTAKE

VALVE

USE WRENCHES

ON FLATS ONLY

135

31

LIPS

OFTHE

.~~-----=:::...<-...,

V-PACKINGS

MUST

FACE

DOWN

137

THROAT

PACKINGS

124

30

127

LIPS

OF

THE

V-PACKINGS

a---'~'

MUST

FACE UP

35

139

TORQUE TO

66-76 ft-Ib

(88-102 N·m)

PISTON

VALVE

Fig

13-------

_______

_

6.

Loosely install the packing nut/wet-cup (141).

7.

Reinstall the displacement rod and intake valve.

Reassembly

(See

Fig

12)

1.

Secure the displacement rod to the motor

with

a

cotter pin (112).

2. Secure the pump housing

(140)

to the tie rods

(116)

and tighten the tie rod locknuts

(114)

evenly

to

35

to

50 ft-Ib

(47

to

68 N·m).

3. Tighten the packing nut just enough

to

stop

leakage,

but

no

tighter.

Fill

the wet-cup

1/4

full

with

TSL.

4.

Install the extension

(62)

assembly or accessory

suction tube.

5.

Start the pump and operate it slowly to check the

tie rods

for

binding. Adjust the tie rod locknuts,

if

necessary,

to

eliminate binding.

6.

Reinstall the pump in its mounting.

7. Before operating the pump, reconnect the sprayer

ground wire

if

it

was disconnected during repair.

307-293

1~